A variable diameter wheel hub

A wheel and hub technology, applied in the field of variable-diameter hubs, can solve the problems of increased energy consumption, inability to meet the driving smoothness, large driving force, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

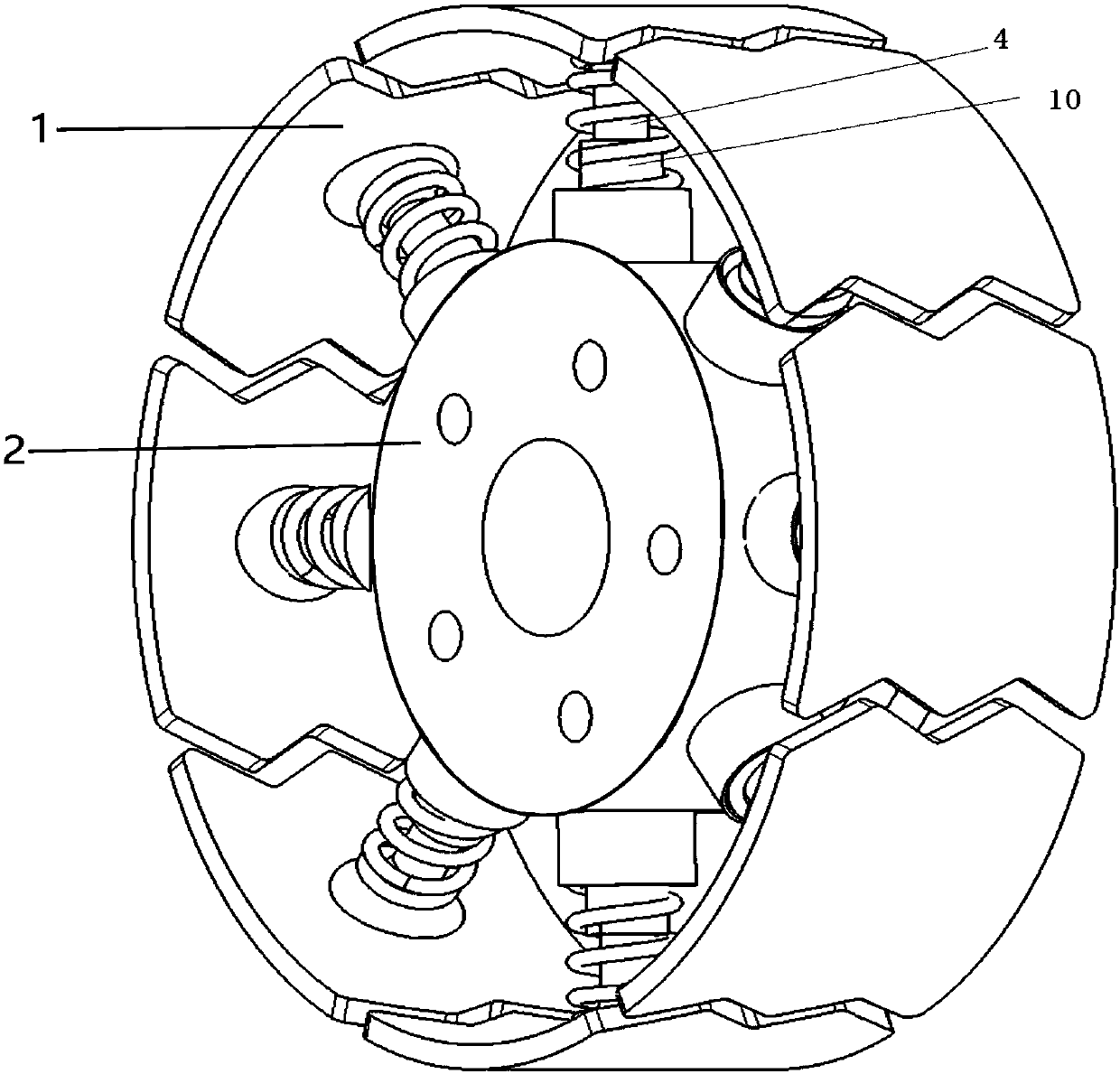

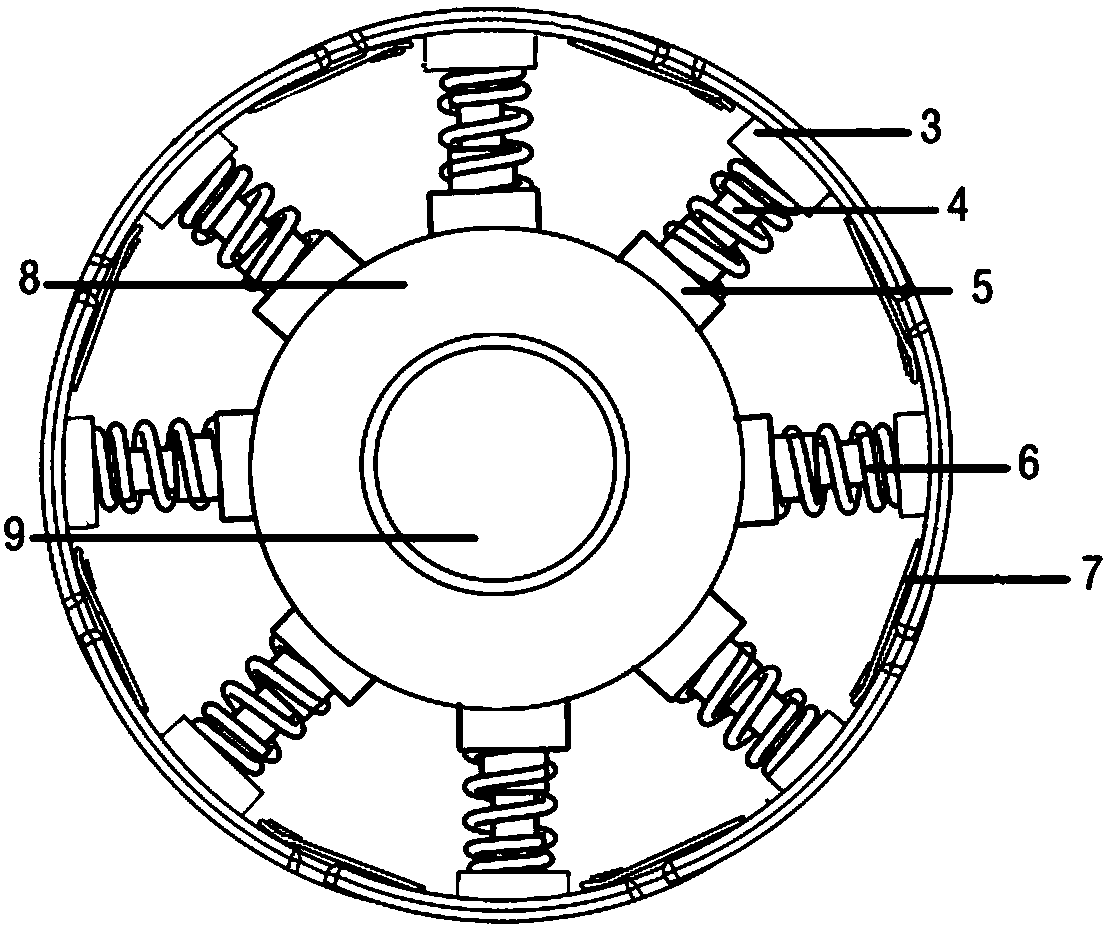

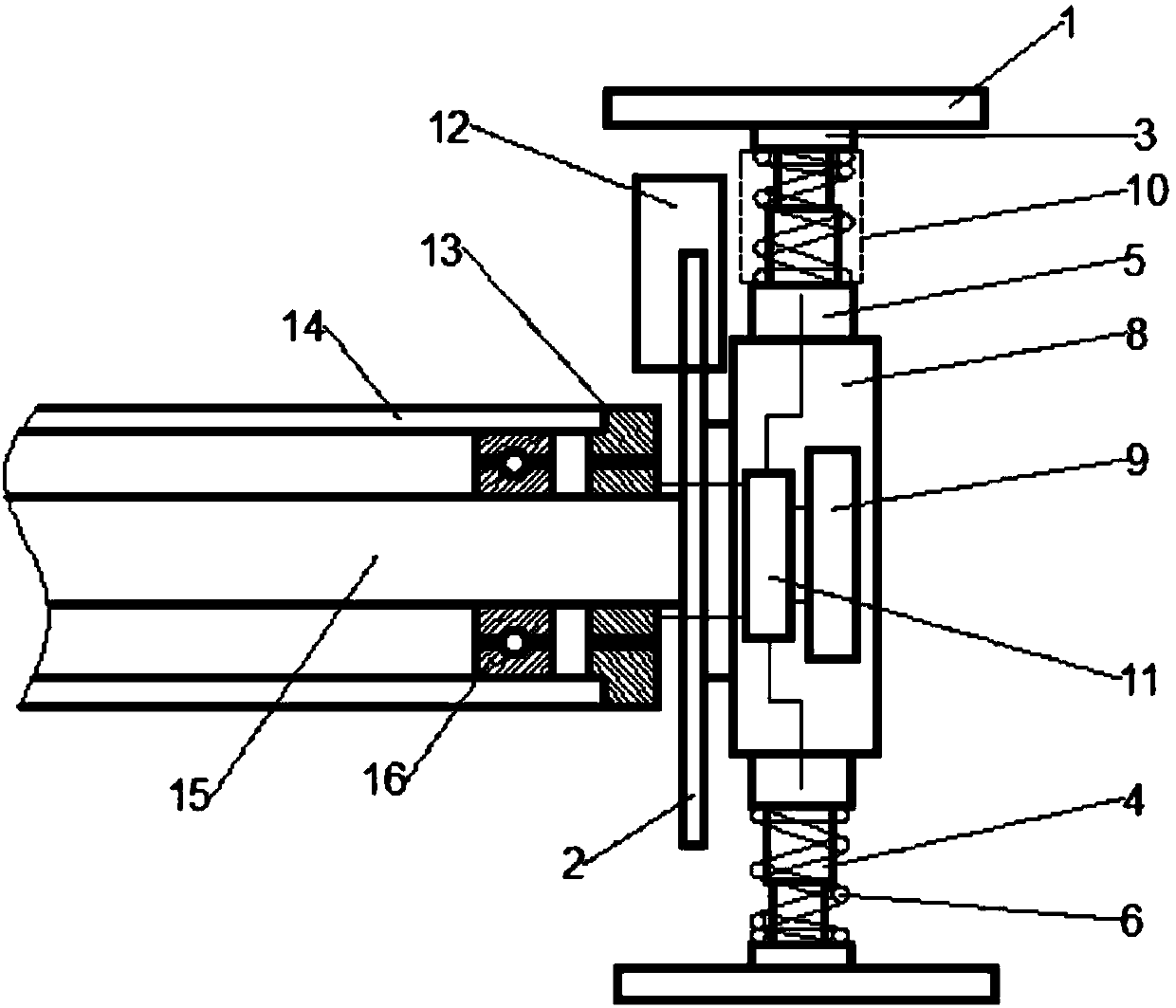

[0034] The variable diameter wheel hub of the present invention is as Figure 1-9 As shown, it belongs to the zigzag splicing wheel rim, such as Figure 1-3 The wheel rim 1 is divided into eight telescopic spoke blocks along the circumferential direction, and two adjacent rim blocks are spliced end to end in a zigzag manner along the circumferential direction to form a circumferential hub surface. Each hub block is connected to the central control cabin 8 at the center of the circle through a telescopic spoke assembly 10 along the radial direction of the spoke, and can move radially under the action of the telescopic spoke assembly 10 .

[0035] The telescopic spoke assembly 10 is a telescopic mechanism composed of a variable damping type telescopic actuator 4 with an elongation booster spring 6 nested on the outer wall (see image 3 The reference numeral 10 drawn by the dotted frame of the dotted line); The inner end of each elongation booster spring 6 contacts with the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com