Bidirectional parallel thrust-lifting type automobile intelligent conveyer

A technology for intelligent handling and automobiles, applied in the direction of buildings, building types, buildings, etc. where cars are parked, it can solve the problems of complex running rails, difficult processing, and unstable transmission of the holding rod, so as to reduce the control cost and control difficulty. , The effect of reducing the preparation time in the early stage and improving the efficiency of car access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below through non-limiting embodiments and in conjunction with the accompanying drawings.

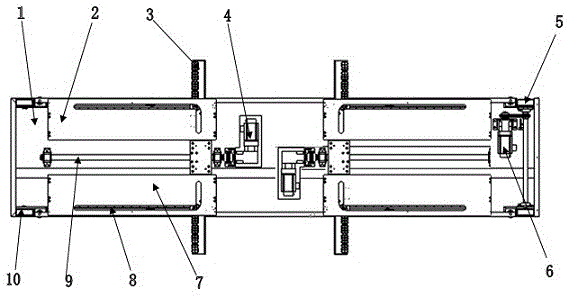

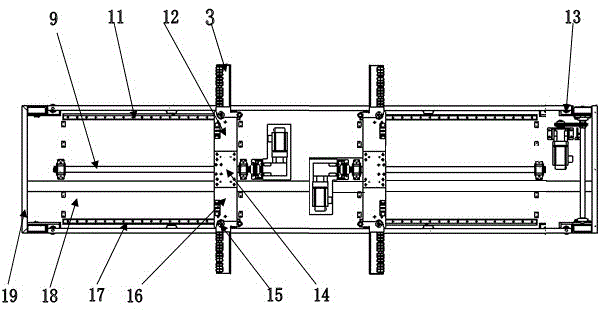

[0052] see Figure 1 to Figure 12 , the present embodiment discloses a two-way parallel push-up type automobile intelligent carrier, which includes a chassis 1, on which a traveling mechanism and a positioning device are arranged; a traveling motor 6, 2 The active traveling wheels 5 and 4 passive traveling wheels 10 are driven by the traveling motor 6 to drive the chain and then drive the 2 active traveling wheels 5, and the traveling mechanism drives the overall movement of the carrier through the traveling motor 6. The chassis 1 is provided with guide wheels 13 on the left frame and the right frame. The six guide wheels 13 are symmetrically distributed on the four corners and the middle sides of the chassis 1. Inclined for smooth operation of the carrier. The positioning device is used to complete the positioning of the chassis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com