Horizontal moving type installation instrument

An installation instrument, translation technology, applied in the direction of transmission, supporting machine, belt/chain/gear, etc., can solve the problems of affecting the accuracy of the experimental process, reducing the efficiency of experimental operation, low instrument positioning accuracy, etc., to achieve precise mechanical positioning. , improve the experimental efficiency, improve the accuracy of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

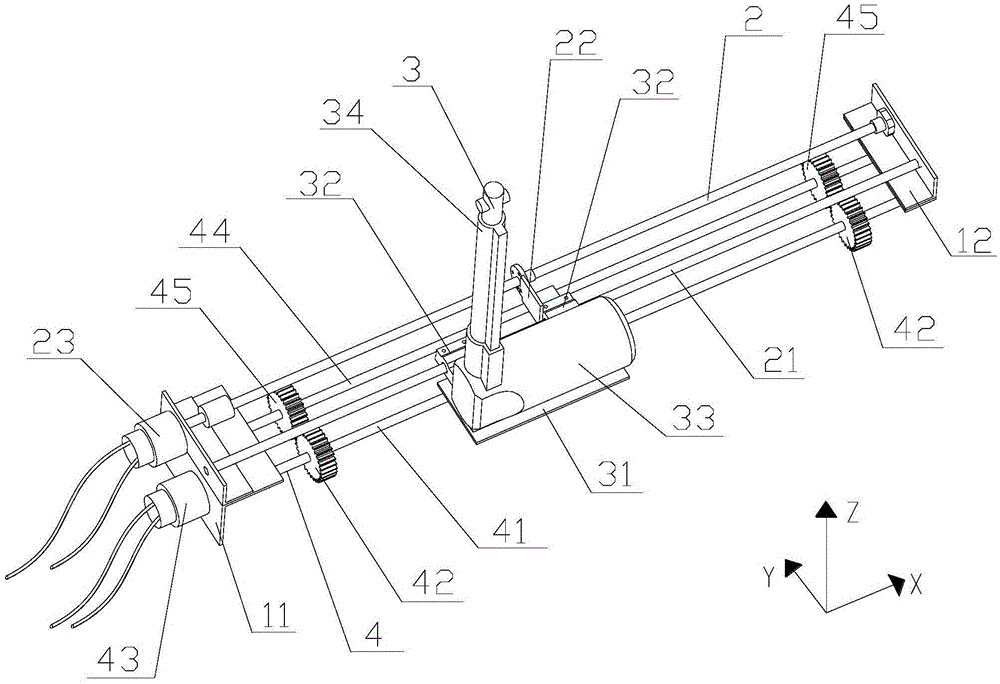

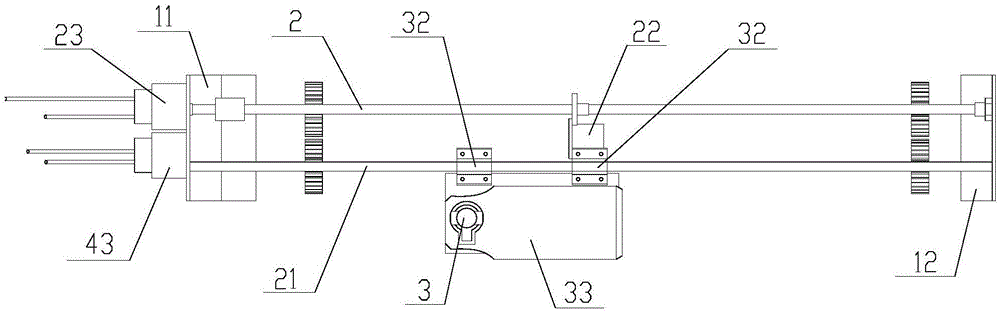

[0016] The following is attached figure 1 with 2 The embodiment of the present invention is given to further illustrate the specific implementation of the translation installation instrument of the present invention. The translational installer of the present invention is not limited to the description of the following embodiments.

[0017] figure 1 with figure 2 The translational installation instrument in includes a mounting frame, a lead screw 2, an underwater acoustic detector 3 and a translation drive mechanism 4, the underwater acoustic detector 3 is screwed to the lead screw 2, and the end of the lead screw 2 is rotated and installed On the mounting frame, the rotation of the lead screw 2 can drive the underwater acoustic detector 3 to move between the two ends of the lead screw 2, that is, the rotation of the lead screw 2 can make the underwater acoustic detector 3 move along the figure 1 The X-axis direction of the middle coordinate system moves; the translation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com