Three-segment type mobile phone shell U cover positioning device

A technology of mobile phone casing and positioning device, applied in coating and other directions, can solve problems such as low production efficiency, poor quality controllability, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

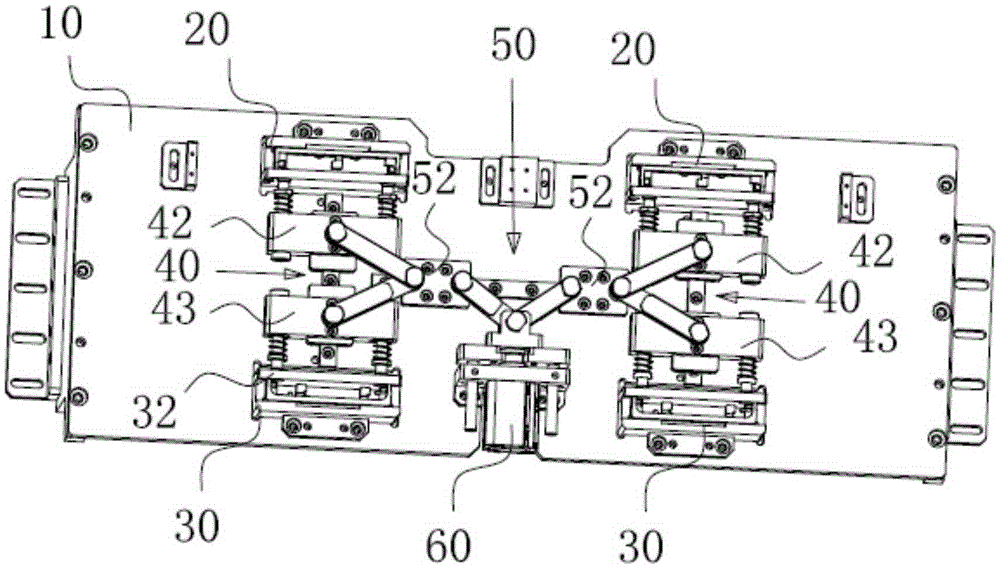

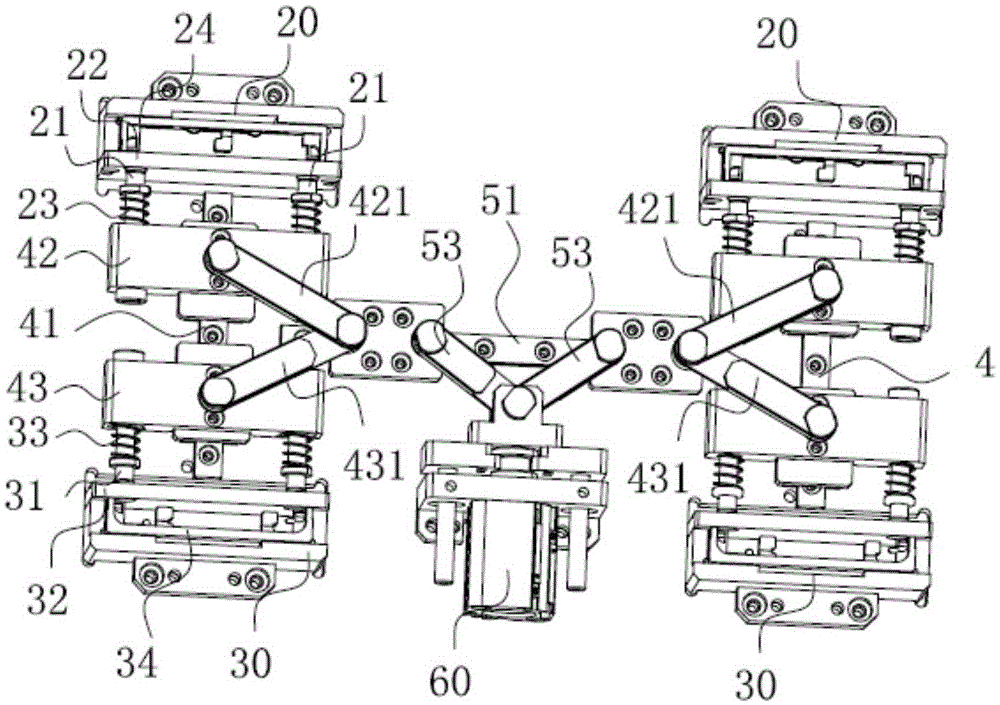

[0033] Such as figure 1 and figure 2 As shown, the three-section mobile phone casing U cover positioning device described in the application, the three-section mobile phone casing U cover positioning device includes a base 10, and a U-shaped upper positioning frame 20 and a U-shaped upper positioning frame affixed to the base 10. The lower positioning box 30. The upper positioning frame 20 and the lower positioning frame 30 are all set to U-shaped, which is convenient for the positioning of the U-shaped upper U cover and the lower U cover, not only positioning the distance between the upper and lower U cover, but also positioning the U cover. correct. The upper positioning frame 20 and the lower positioning frame 30 are arranged oppositely, and a push rod device is arranged between the upper positioning frame 20 and the lower positioning frame 30. The push rod device includes an upper push rod 21, a lower push rod 31, and drives the upper push rod 21 and the lower push rod....

Embodiment 2

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, and the similarities will not be repeated here. The difference between it and Embodiment 1 mainly lies in:

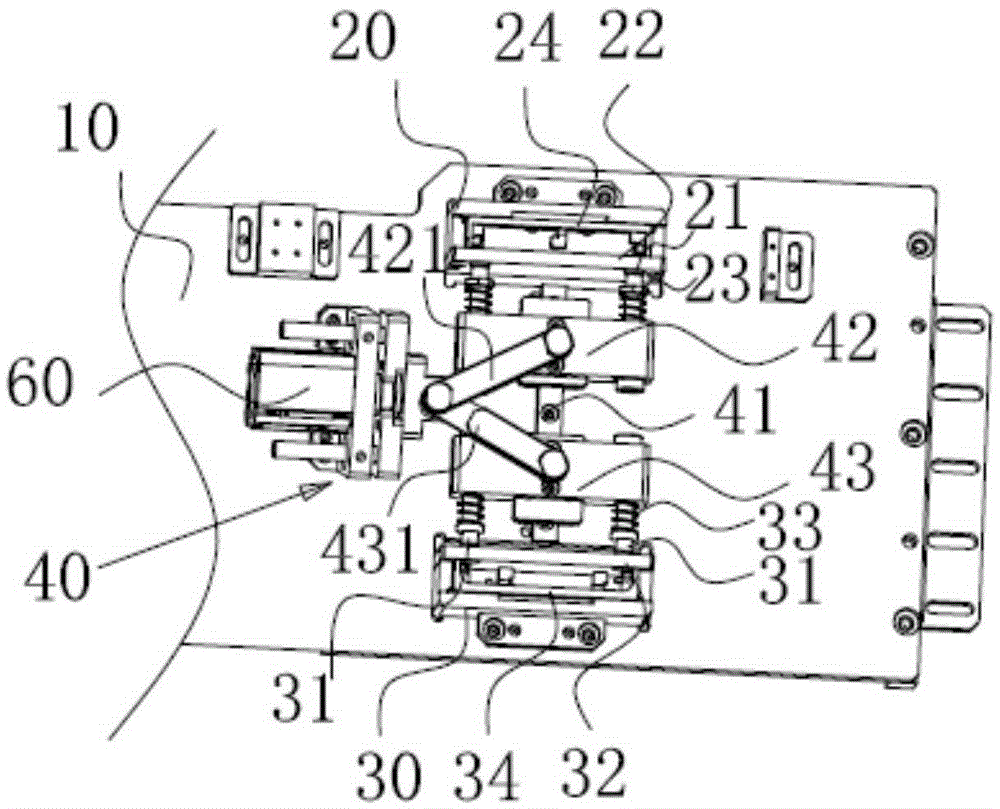

[0046] Such as image 3 As shown, the driving device includes a longitudinal driving device 40 and a driver 60, and the longitudinal driving device 40 includes a longitudinal linear guide rail 41, a longitudinal upper slider 42, a longitudinal lower slider 43, and a longitudinal upper driving arm 421, a longitudinal lower driving arm 431, an upper top One end of the rod 21 is fixedly connected to the vertical upper slider 42, and one end of the lower ejector rod 31 is fixedly connected to the vertical lower slider 43. The direction of the longitudinal linear guide 41 is along the direction from the upper positioning frame 20 to the lower positioning frame 30. The slide block 42 and the longitudinal lower slide 43 can slide on the longitudinal linear guide rail 41, one end of the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com