Hot stamping automatic line transfer manipulator and usage method

A manipulator, automatic line technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., to achieve the effects of precise mechanical positioning, easy maintenance, high static strength and fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

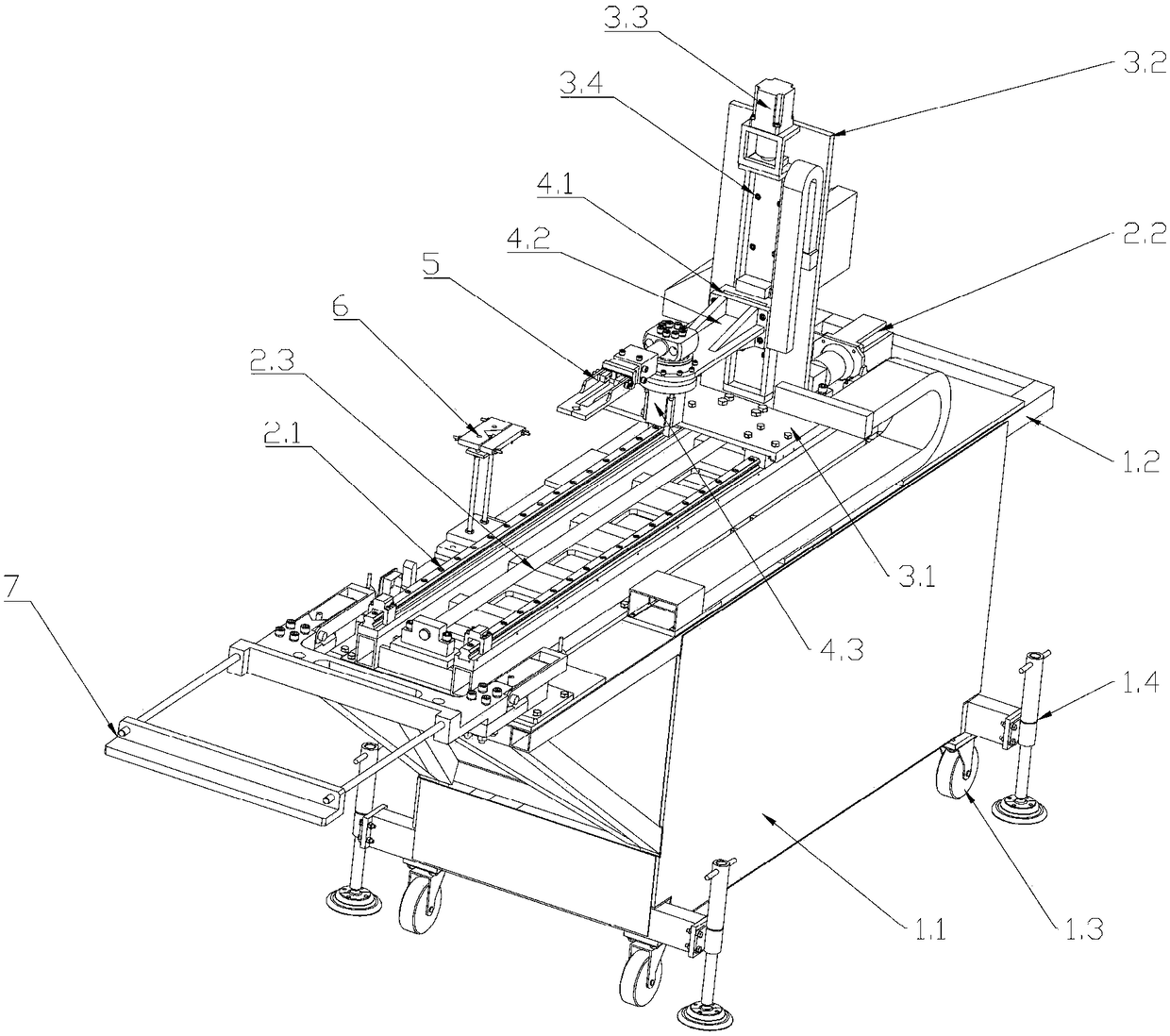

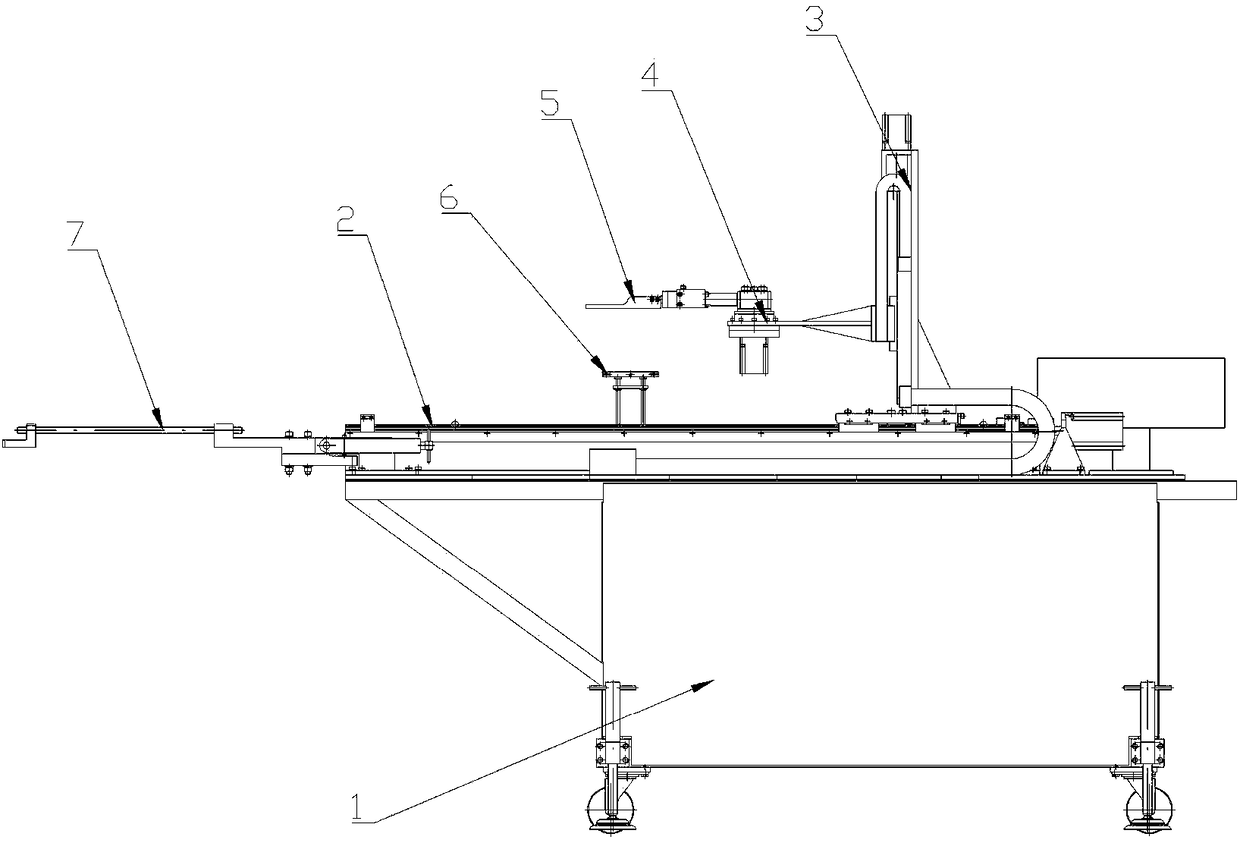

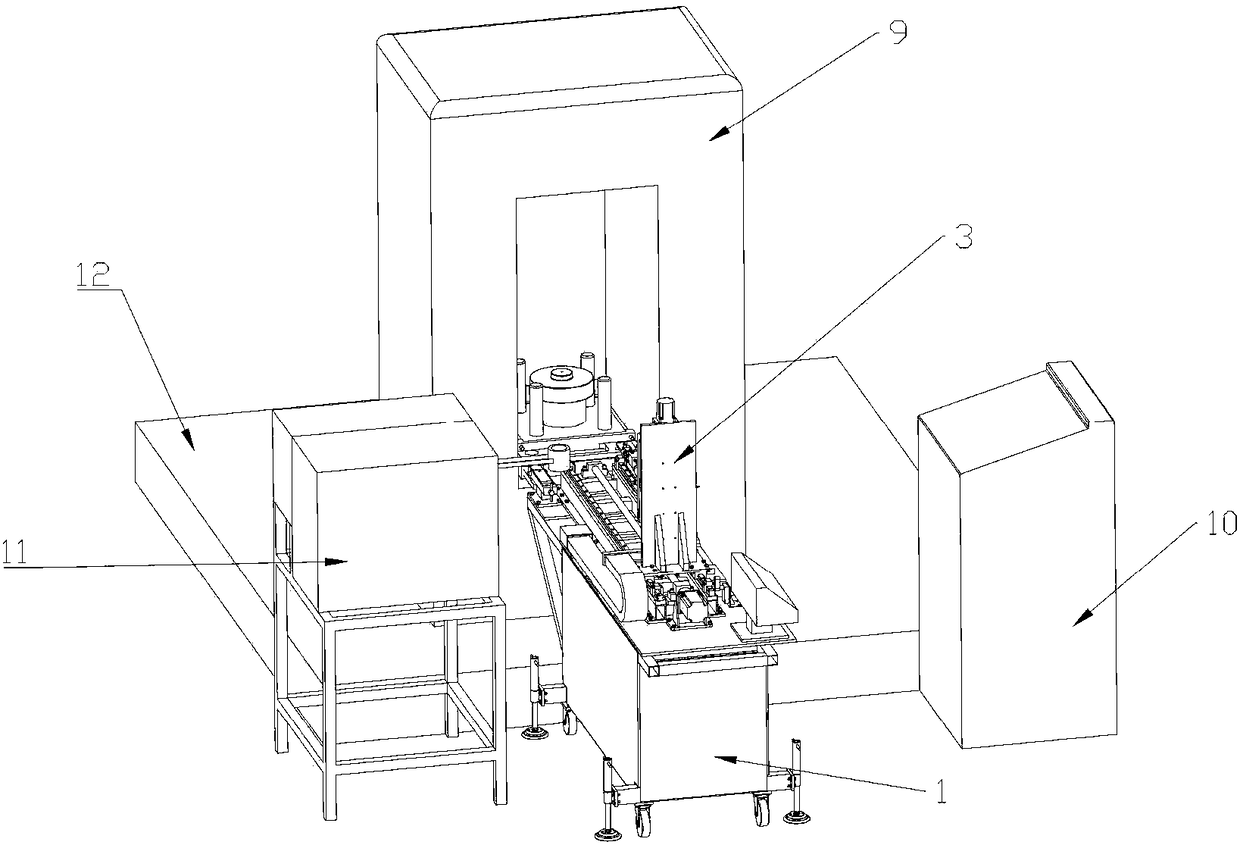

[0034] Such as Figure 1-5 A hot stamping automatic line transfer manipulator is shown, including a movable supporting mechanism 1, an X-axis moving mechanism 2, a Z-axis lifting mechanism 3, an A-axis rotating mechanism 4 and a clamping mechanism 5;

[0035] The X-axis moving mechanism 2 has an X-axis slideway 2.1 arranged on the movable support mechanism 1, an X-axis servo motor 2.2 and an X-axis transmission mechanism 2.3; the X-axis slideway 2.1 supports the Z-axis lifting mechanism 3 and defines The walking track of the Z-axis lifting mechanism 3 on the X-axis; the X-axis servo motor 2.2 and the X-axis transmission mechanism 2.3 are used to drive the Z-axis lifting mechanism 3 to move on the X-axis slideway 2.1;

[0036] The Z-axis lifting mechanism 3 has a Z-axis base 3.1 that is arranged on the X-axis slideway 2.1 and is connected with the X-axis transmission mechanism 2.3. The Z-axis base 3.1 is vertically provided with a Z-axis mounting plate 3.2, and on the Z-axis mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com