Slide bar type positioning mechanism

A positioning mechanism and sliding rod technology, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of affecting the accuracy of the experimental process, reducing the efficiency of experimental operation, and low positioning accuracy of instruments, so as to achieve simple structure and improve experimental efficiency , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

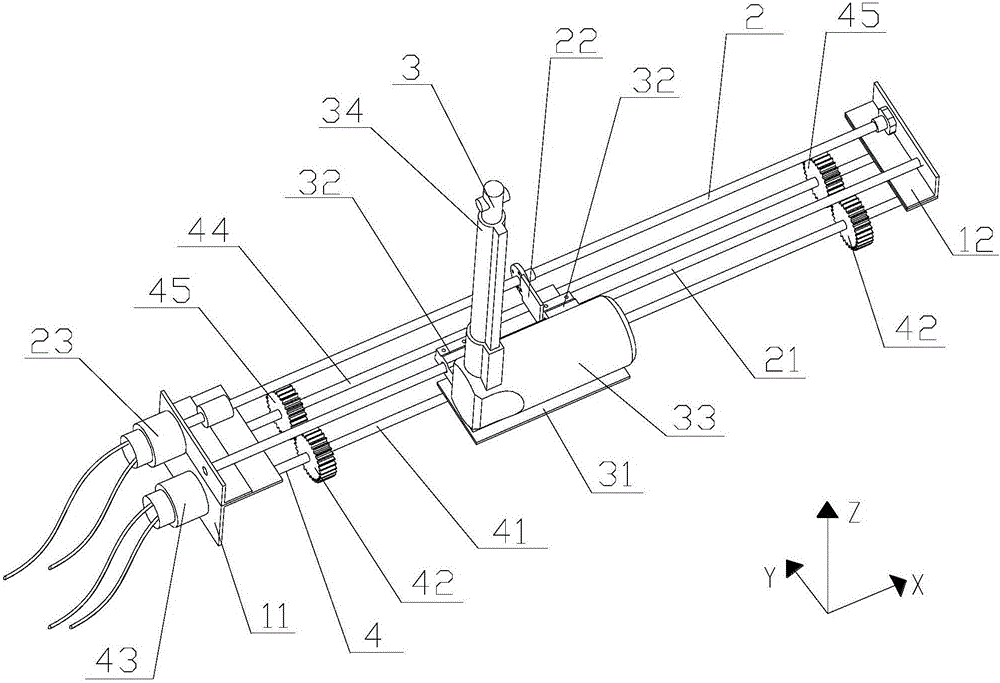

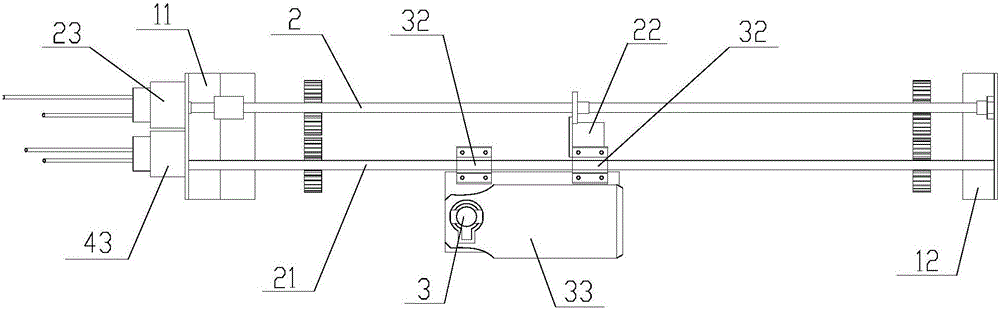

[0016] The following is attached figure 1 and 2 The embodiment of the present invention is given to further illustrate the specific implementation of the slide bar positioning mechanism of the present invention. The sliding bar positioning mechanism of the present invention is not limited to the description of the following embodiments.

[0017] figure 1 and figure 2 The slide bar type positioning mechanism in includes a mounting frame, a lead screw 2, a hydroacoustic detector 3 and a translation drive mechanism 4, and the hydroacoustic detector 3 is threadedly connected with the lead screw 2, and the end of the lead screw 2 rotates Installed on the mounting frame, the rotation of the lead screw 2 can drive the underwater acoustic detector 3 to move between the two ends of the lead screw 2, that is, the rotation of the lead screw 2 can make the underwater acoustic detector 3 move along the figure 1 The X-axis direction of the middle coordinate system moves; the translatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com