Substrate, substrate manufacturing method, touch screen, and display device

一种制造方法、基板的技术,应用在光学、仪器、电数字数据处理等方向,能够解决影响显示画面清晰度、表面分子结构不均匀、增大玻璃表面雾度等问题,达到提高显示效果、可实施性强、降低光线反射程度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] The invention provides a substrate, a manufacturing method of the substrate, a touch screen and a display device. The substrate is provided with a layer of anti-reflection and anti-reflection film on the base substrate, and the anti-reflection and anti-reflection film includes a nanoporous layer. It can effectively increase the degree of light transmission, reduce the degree of light reflection, realize shadow elimination, and finally improve the display effect.

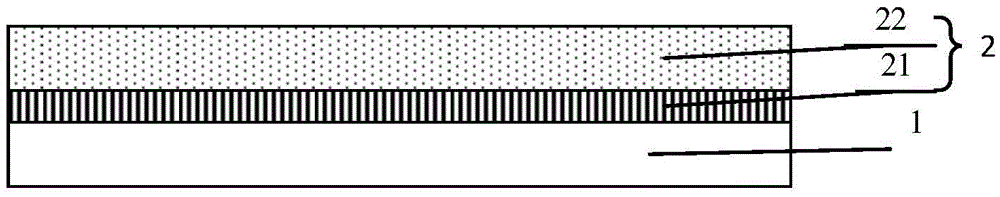

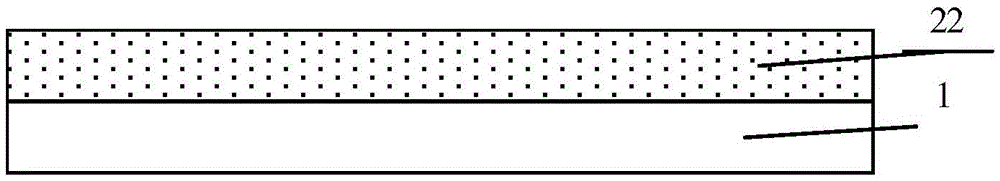

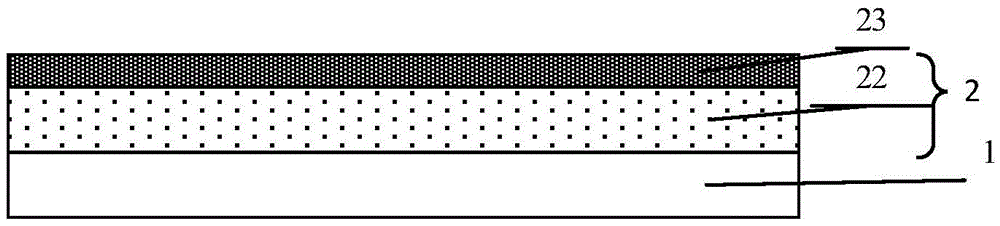

[0041] This embodiment provides a substrate, such as figure 1 As shown, it includes a base substrate 1 and an anti-reflection and anti-reflection film 2 disposed on the base substrate 1 , and the anti-reflection and anti-reflection film 2 includes a nanop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| apparent porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com