Method for preventing and controlling rock burst remained under coal pillar

A technology of legacy coal pillars and rock burst, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as complex processes, achieve high safety factor, reduce transmission effect, and eliminate impact hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

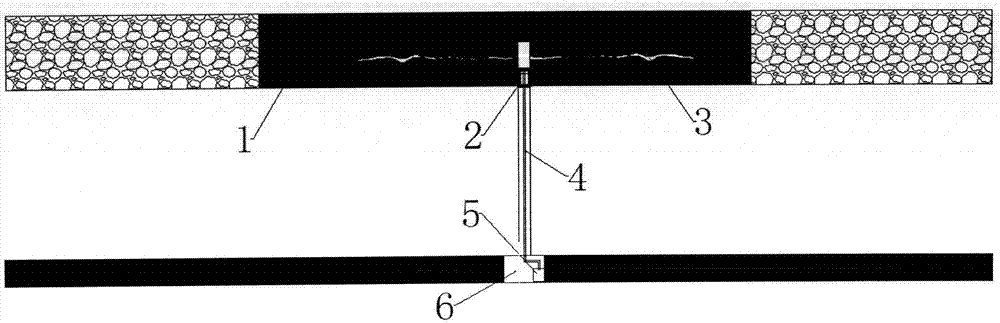

[0018] A method for prevention and control of rockburst under the left coal pillar, such as figure 1 shown. The steps are as follows:

[0019] Select a mining face affected by the coal pillar left above, the width of the coal pillar is more than 20m, and the vertical distance does not exceed 50m. Analyze the size of the coal pillar and the layout of the current working face, determine the positional relationship between the two, and draw the plan and section.

[0020] Carry out the drilling construction design according to the drawn plane and section drawings. The construction location is the tunnel roadway of the working face. figure 1 shown.

[0021] Install a drilling rig for construction, and select a suitable drilling rig for operation according to the construction quantity and site conditions. Before construction, use surveying and mapping tools to determine the angle of the drilling rig. The drilling diameter is 75mm, and the drilling spacing is 20m.

[0022] During...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com