Vehicle motor with charging control function

A charging control and function technology, applied in the field of vehicle motors with built-in charging control function, can solve the problems of low transmission efficiency, increased power transmission loss, and increased circuit configuration complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

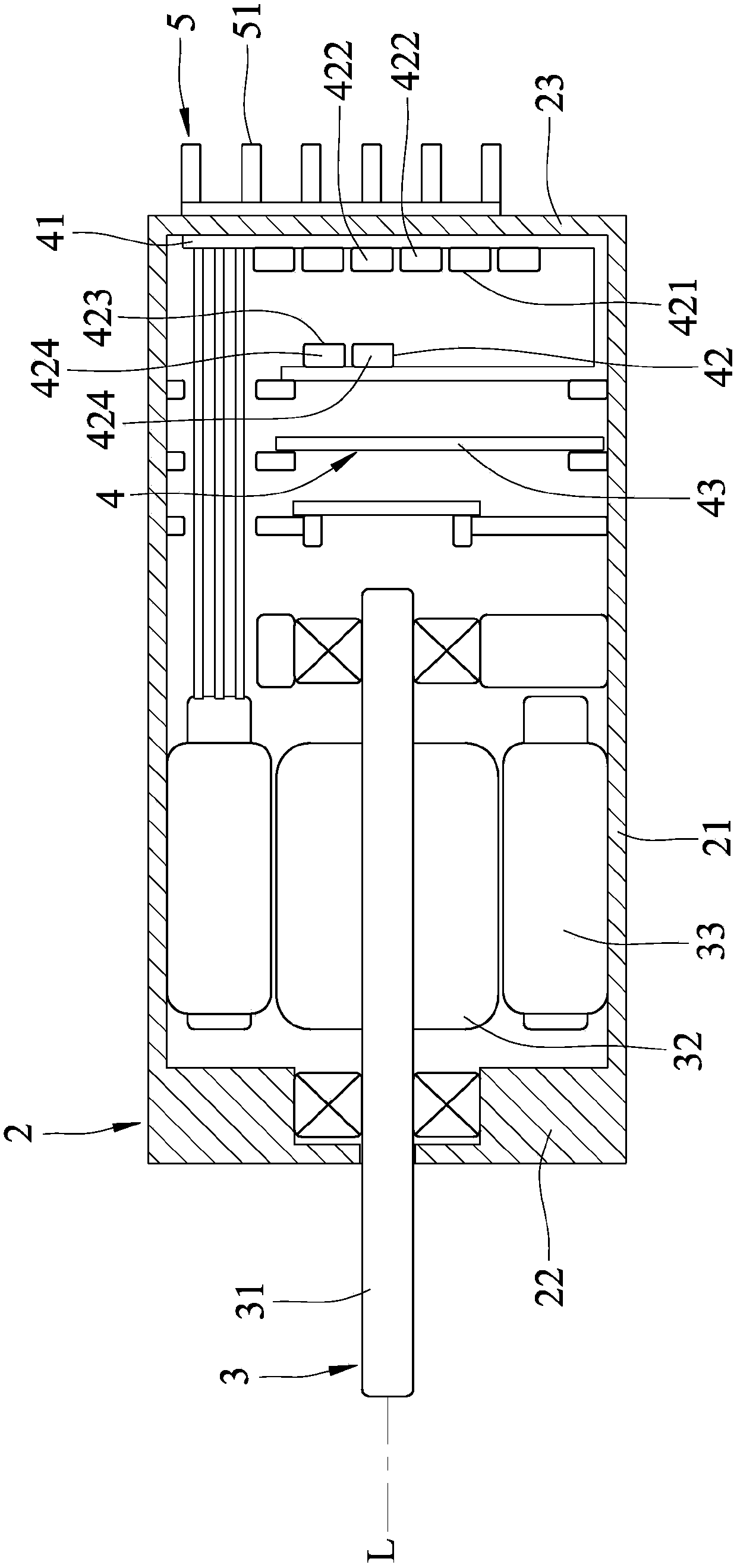

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0026] For convenience of description, in the following embodiments, the same components are denoted by the same reference numerals.

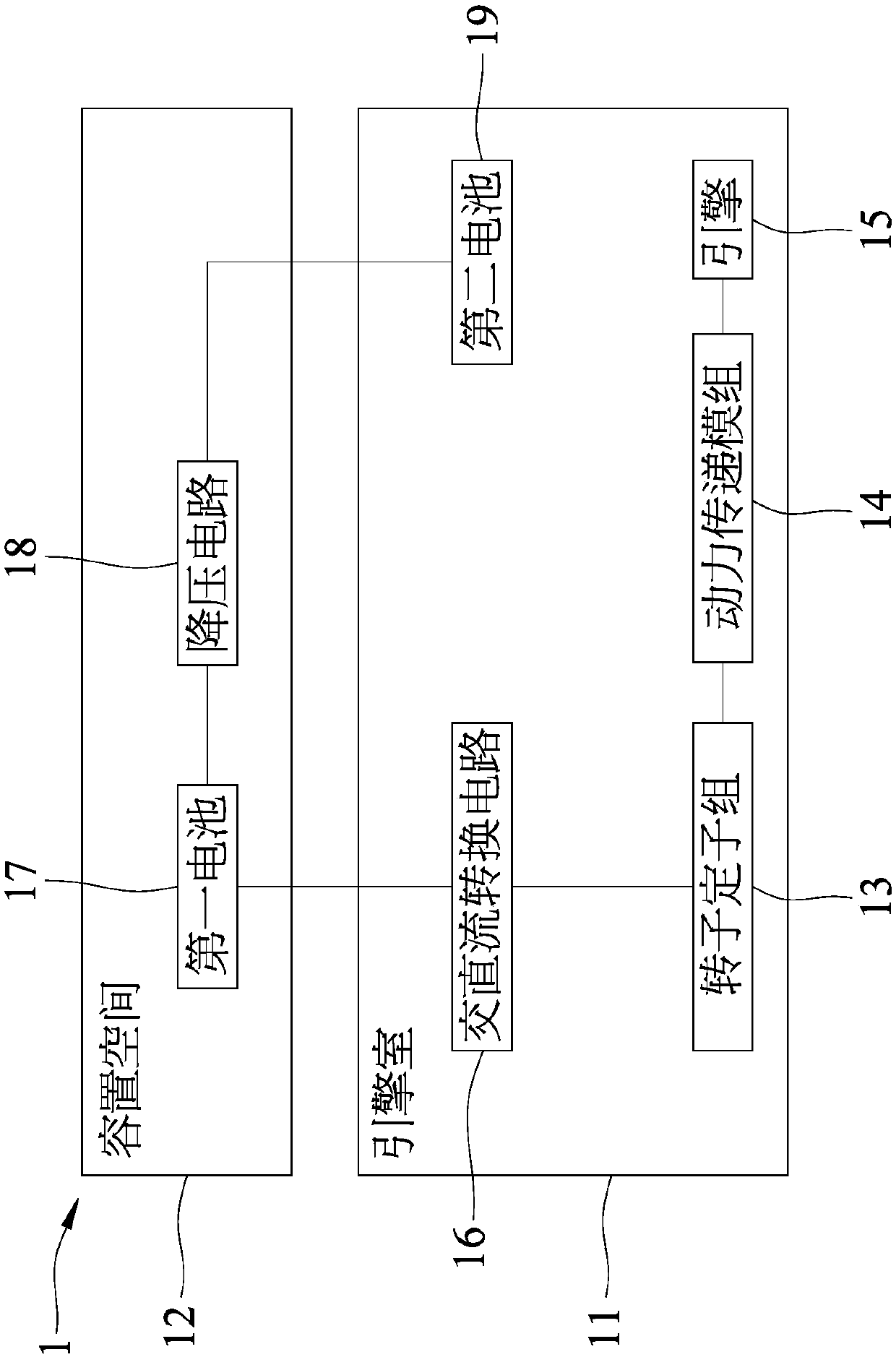

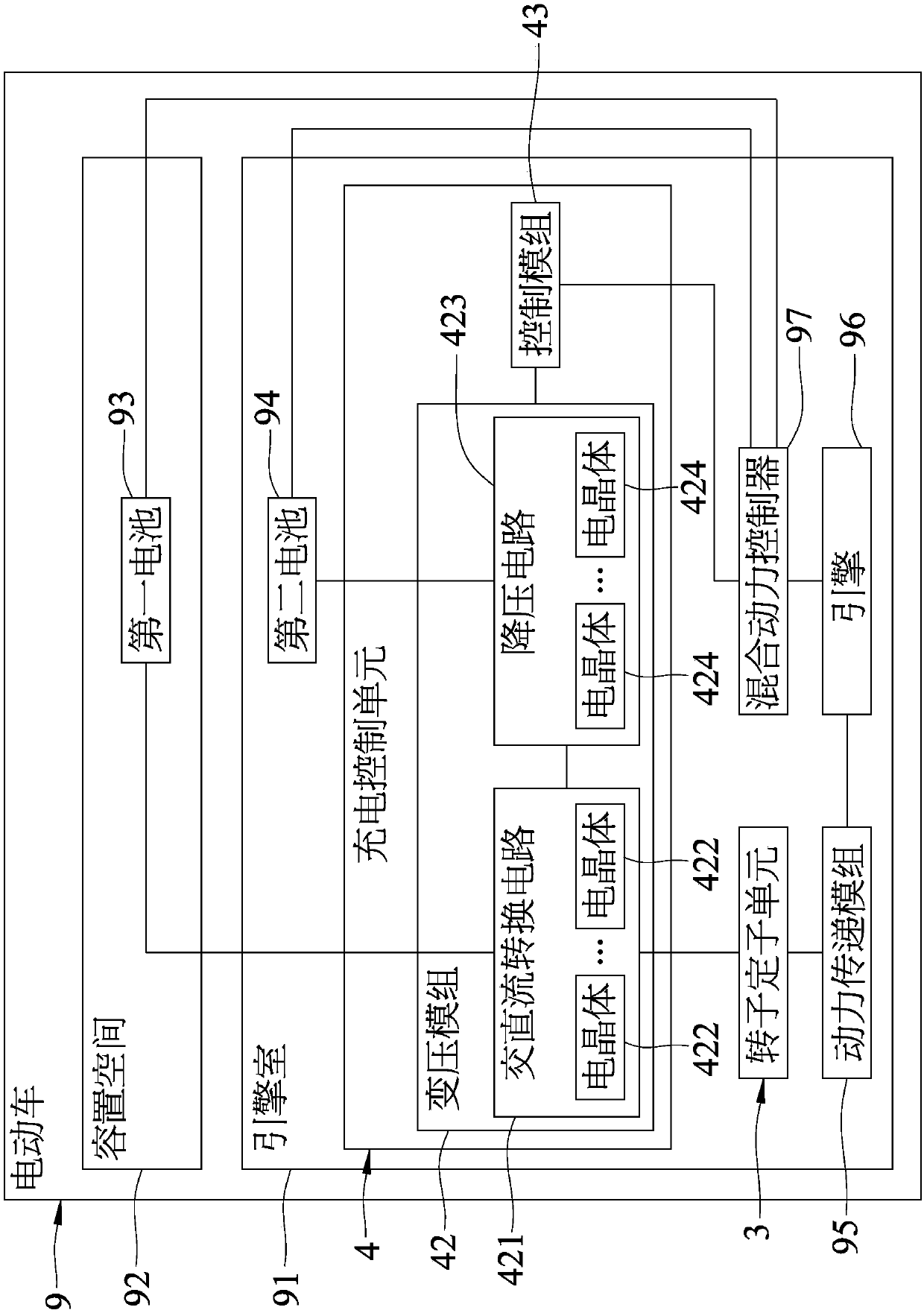

[0027] refer to figure 2 , 3 , a first embodiment of the vehicle motor with a built-in charging control function of the present invention is used for an electric vehicle 9, and the electric vehicle 9 includes an engine compartment 91 located at the front side, an accommodating space 92 located at the rear side, A first battery 93 storing a first DC voltage, a second battery 94 storing a second DC voltage lower than the first DC voltage, and a power transmission linking multiple wheels (not shown) module 95 , an engine 96 linked to the power transmission module 95 , and a hybrid controller 97 electrically connected to the first battery 93 , the second battery 94 and the engine 96 .

[0028] The first battery 93 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com