Lean product modeling systems and methods

A product modeling and product technology, applied in the field of lean product modeling systems and methods, can solve the problems of time and cost increase in the final deployment or integration of products or applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

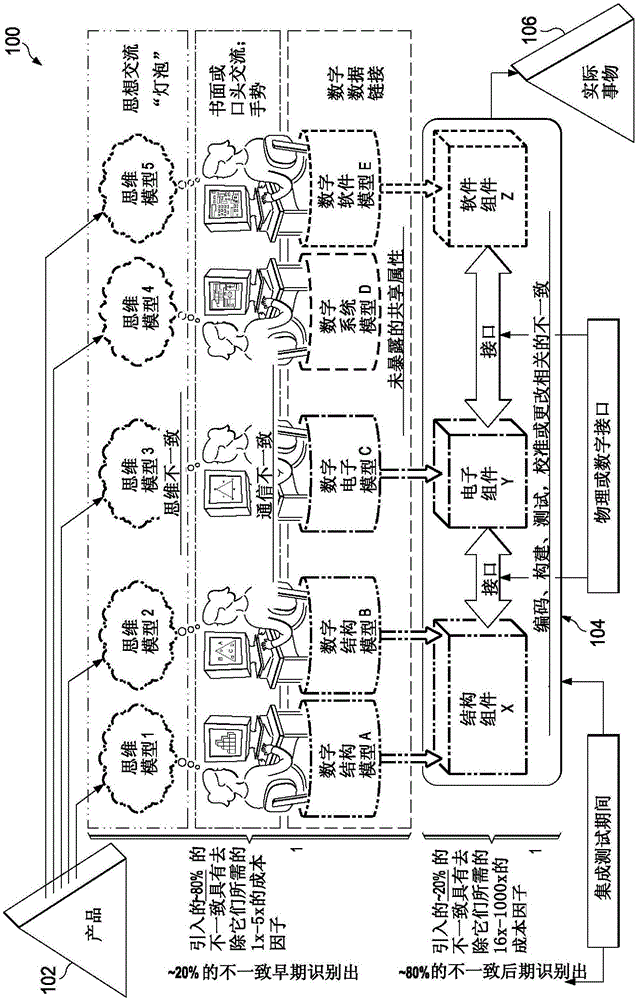

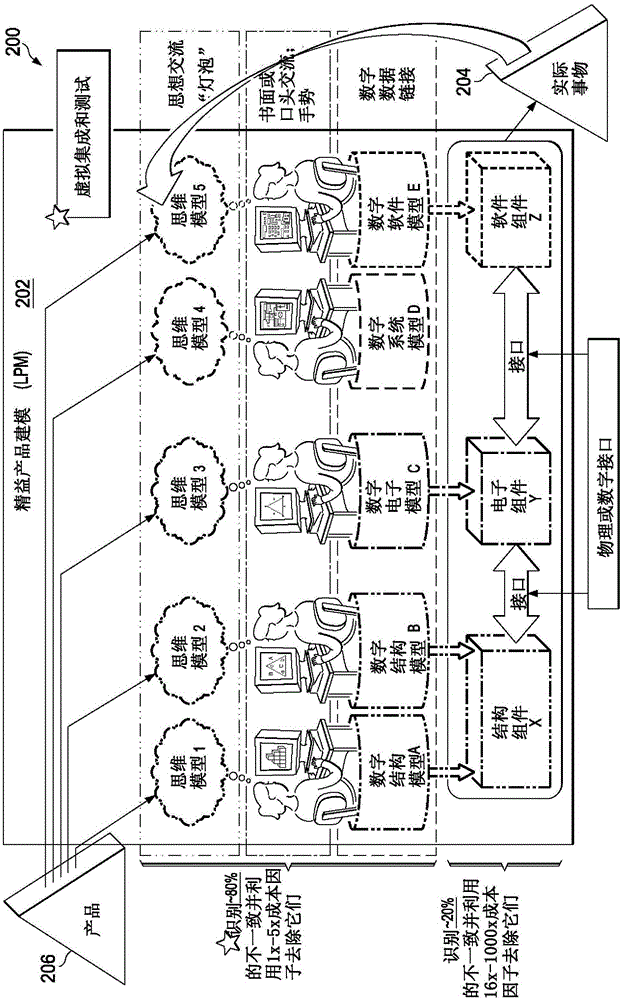

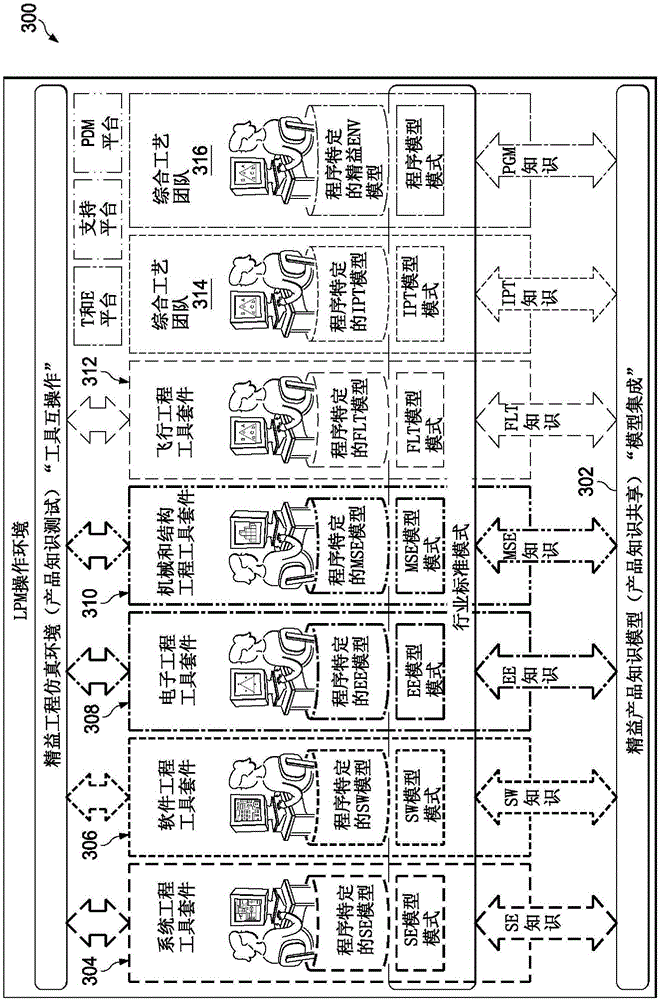

[0025] The illustrative embodiments provide several useful functions. For example, the illustrative embodiments recognize and take into account that the process of developing a product or an application as a service can be expensive in time, resources, and money. The illustrative embodiments recognize and take into account that traditional models for developing products and applications can be prone to inconsistencies.

[0026] The illustrative embodiments recognize and take into account that, in the past, inconsistencies in isolated engineering design models had to be propagated into testable systems in order to detect the inconsistencies. Also, system testing alone may only confirm that the testable system matches the design model. Thus, in the past, many of the design inconsistencies that were initially introduced into the design model could not have been identified and addressed until integrated system testing was performed. The impact of delayed defect identification an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com