Integrated cleaning fixture capable of automatically fixing silicon wafer during rotation

A technology for automatic rotation and cleaning of jigs, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning flexible objects, etc., can solve problems such as low replacement efficiency, impossible cleaning of the back, easy eccentric rotation, etc., to improve productivity and avoid Clamp eccentricity and the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

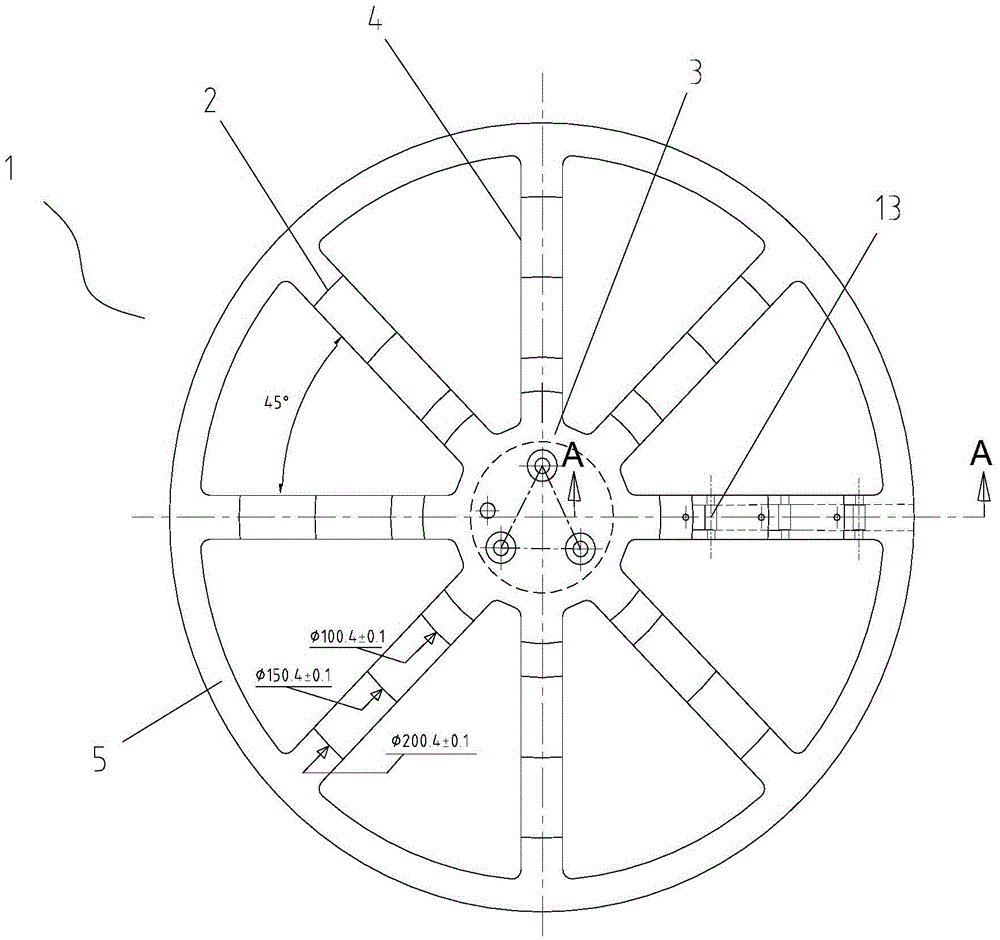

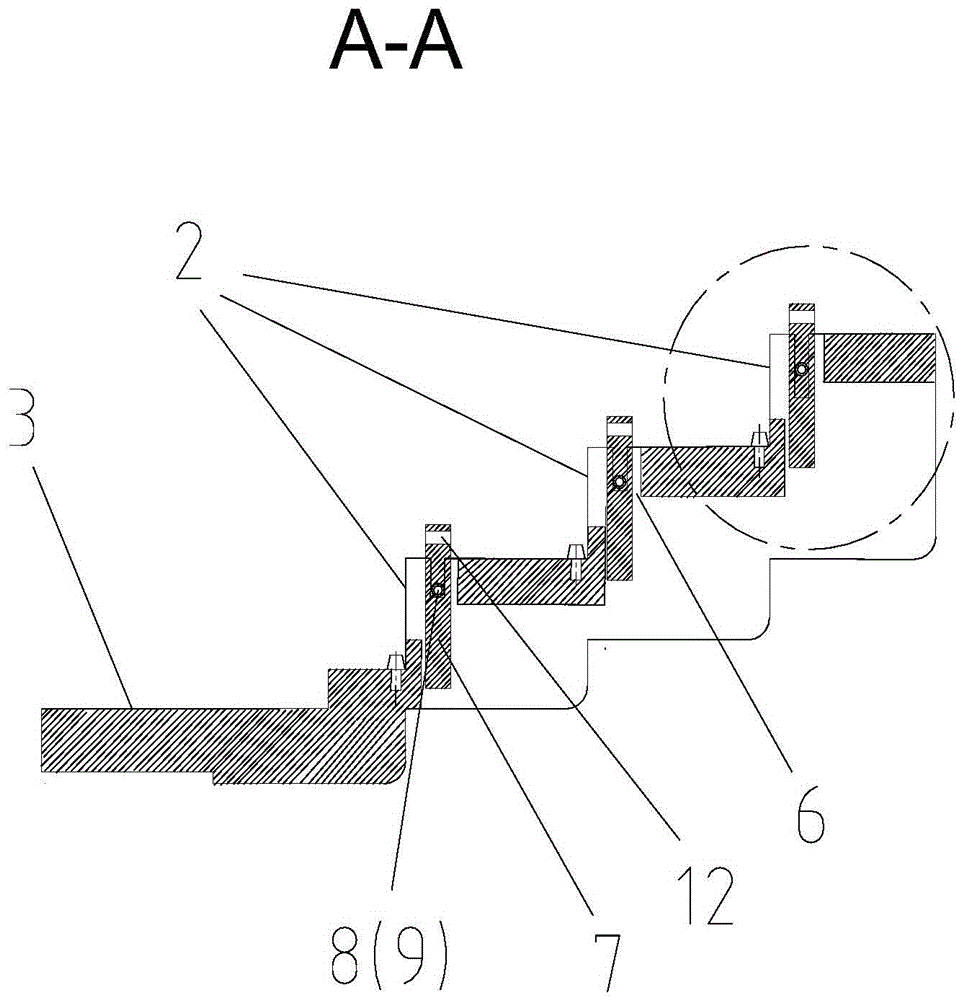

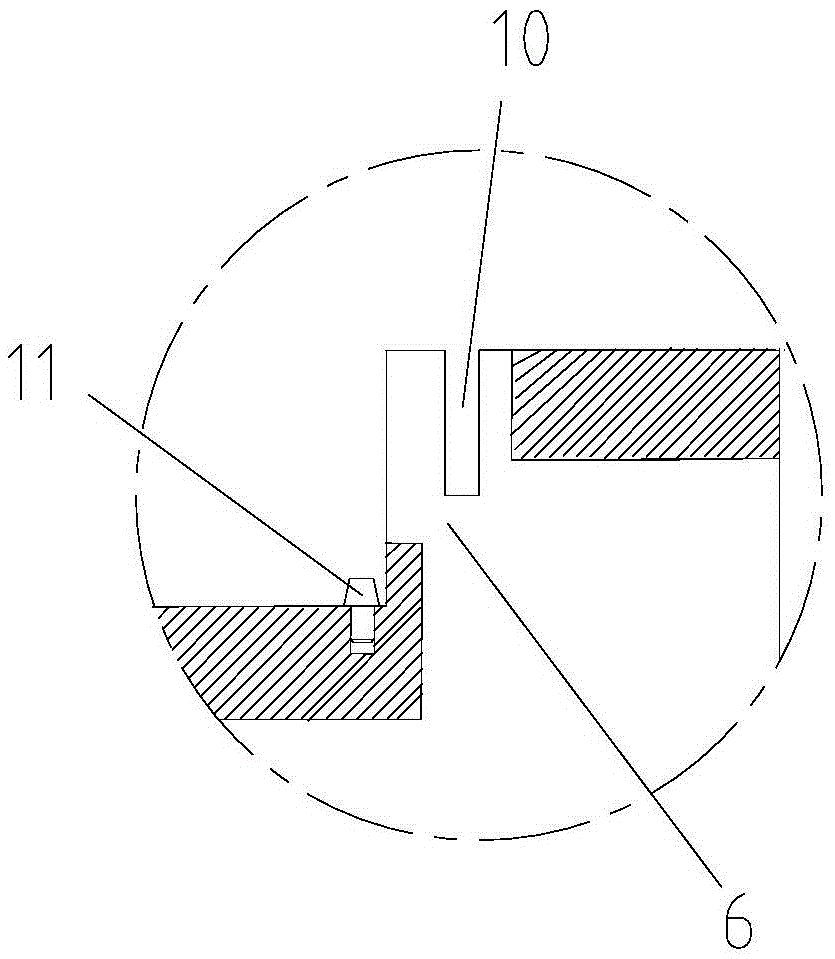

[0026] As shown in the figure, the integrated cleaning jig for automatically rotating and fixing silicon wafers in this embodiment includes a silicon wafer fixing plate 1, and a plurality of circular arc clamping rings 2 with different diameters are arranged on the silicon wafer fixing plate. A centrifugal pressing device 13 for fixing silicon wafers. Specifically, three arc clamping rings 2 with diameters of Φ100.4mm, Φ150.4mm, and Φ200.4mm are arranged on the silicon wafer fixing plate, which can hold the Silicon wafers with diameters of Φ100.4mm, Φ150.4mm, and Φ200.4mm are clamped and fixed, which is beneficial to improve their scope of application and reduce costs. A plurality of ribs 4 extending outward around the support plate 3 and a reinforced outer ring 5 arranged at the ends of the ribs 4 can connect and fix all the ribs together....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com