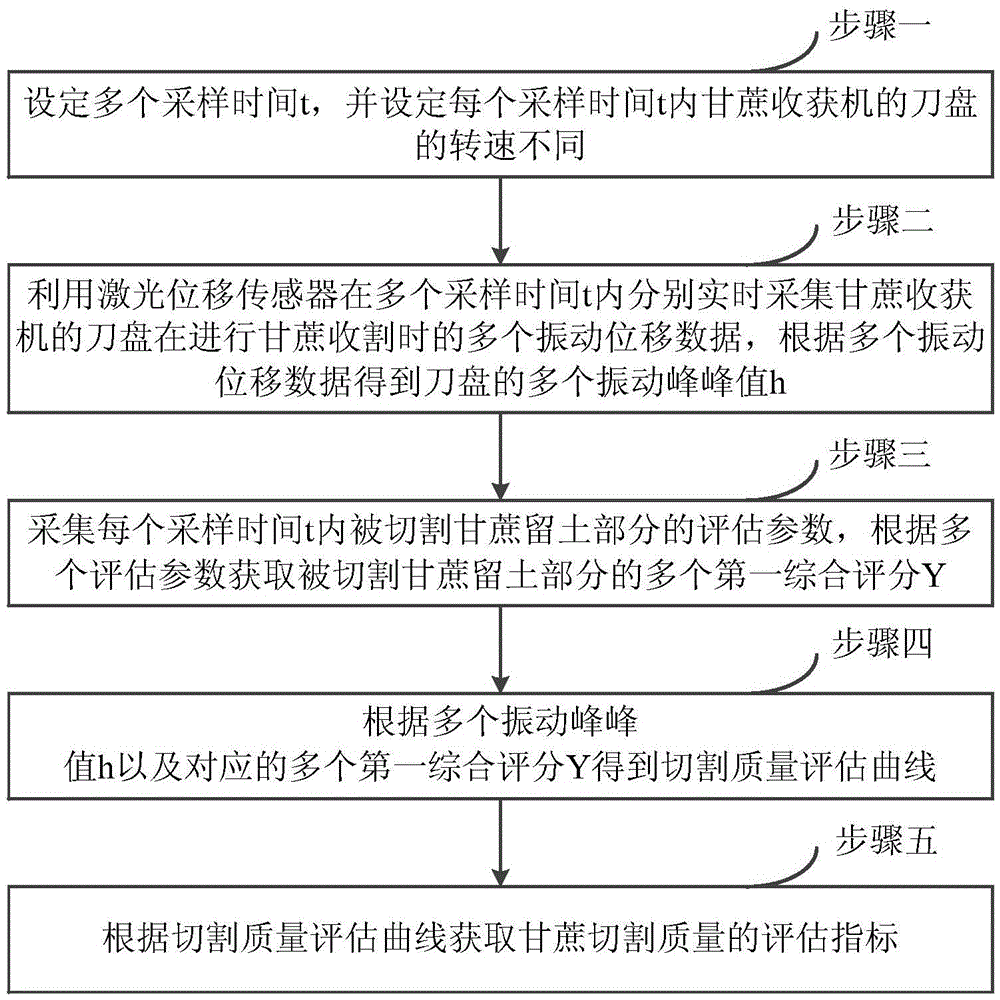

Cutting quality evaluation method and device based on sugarcane harvesting machine cutter head vibration

A quality assessment, harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as increasing planting costs, save manpower and material resources, and facilitate later preservation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

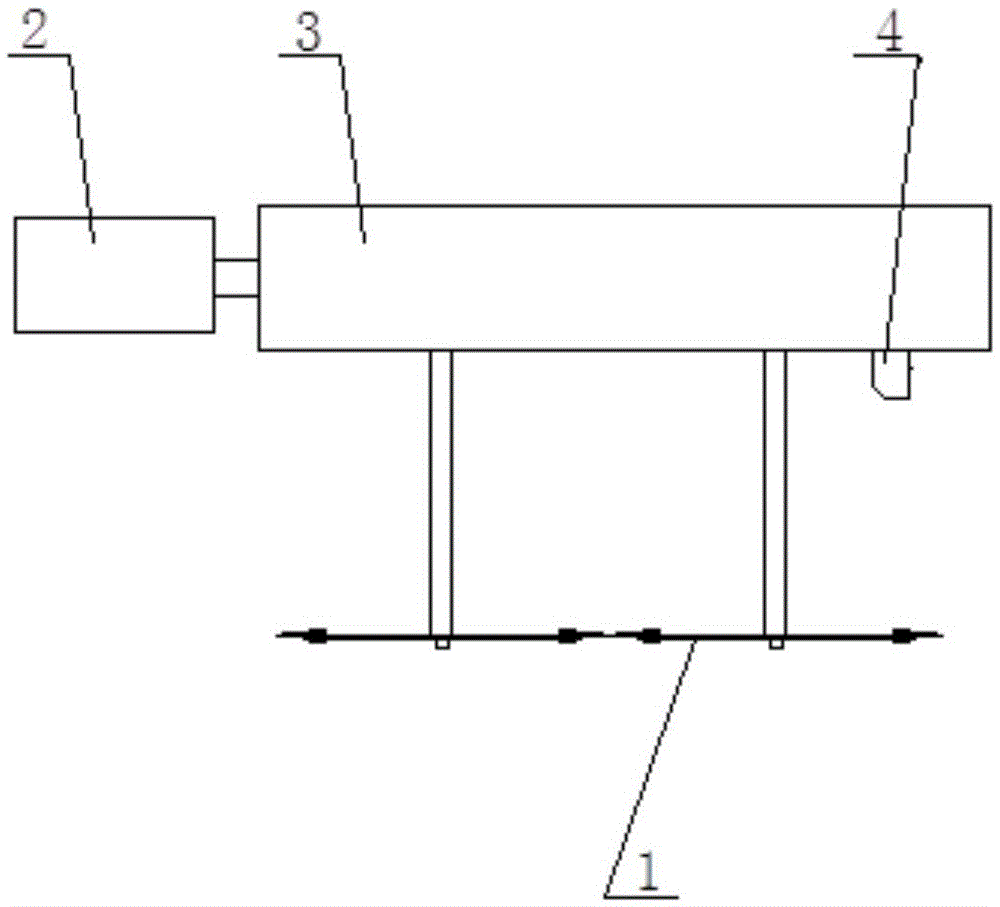

[0044] like figure 2 As shown, the LK-G150A laser displacement sensor 4 produced by Keyence Corporation of Japan is installed directly above the cutter head 1 of the sugarcane harvester to sample the cutter head 1. The cutter head 1 is driven by a hydraulic motor 2 through a gearbox 3. The laser displacement sensor 4 is composed of a measuring head and a controller. The maximum sampling frequency is 50KHz, and the input voltage is 24V. When the sampling frequency is set to 5KHz, it can accurately measure the position of the cutterhead 1 and output electrical signals;

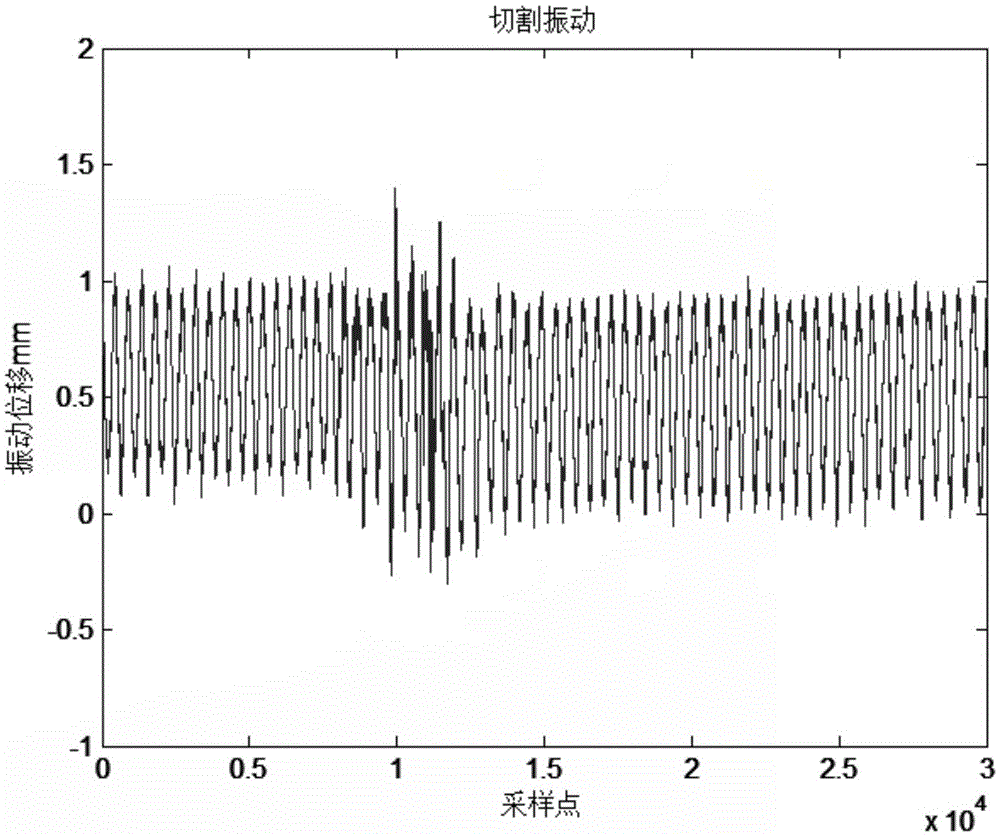

[0045] The laser displacement sensor 4 collects the vibration displacement data in real time within the sampling time t, obtains the time-domain waveform of the vibration displacement, and then performs statistical processing to obtain the vibration peak-to-peak value h within the sampling time t; see for details image 3 ;

[0046] Through manual measurement and collection of a series of data on the number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com