A Calculation Method of Thermal Performance of Cooling Tower Filling Based on Two-point Boundary Value Measurement

A technology of thermal performance and calculation method, which is applied in the field of thermal performance calculation of cooling tower filler based on two-point boundary value measurement, can solve the problems of long evaluation time, a large number of training samples, and large calculation errors, so as to reduce calculation time and ensure calculation Accurate, adaptable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

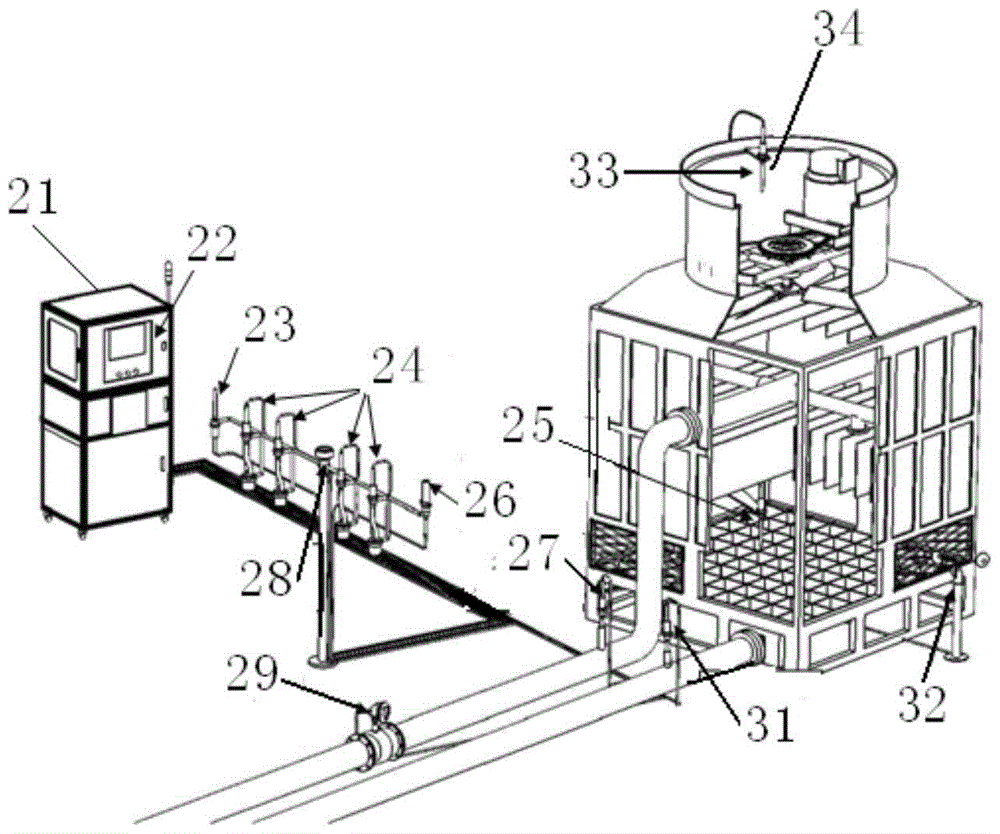

[0020] In order to make the purpose, technical solution and advantages of the present invention more clear, the following will further describe the embodiment of the present invention in detail in conjunction with the accompanying drawings, taking the calculation of the thermal performance of the CEF-370 stainless steel countercurrent square tower as an example:

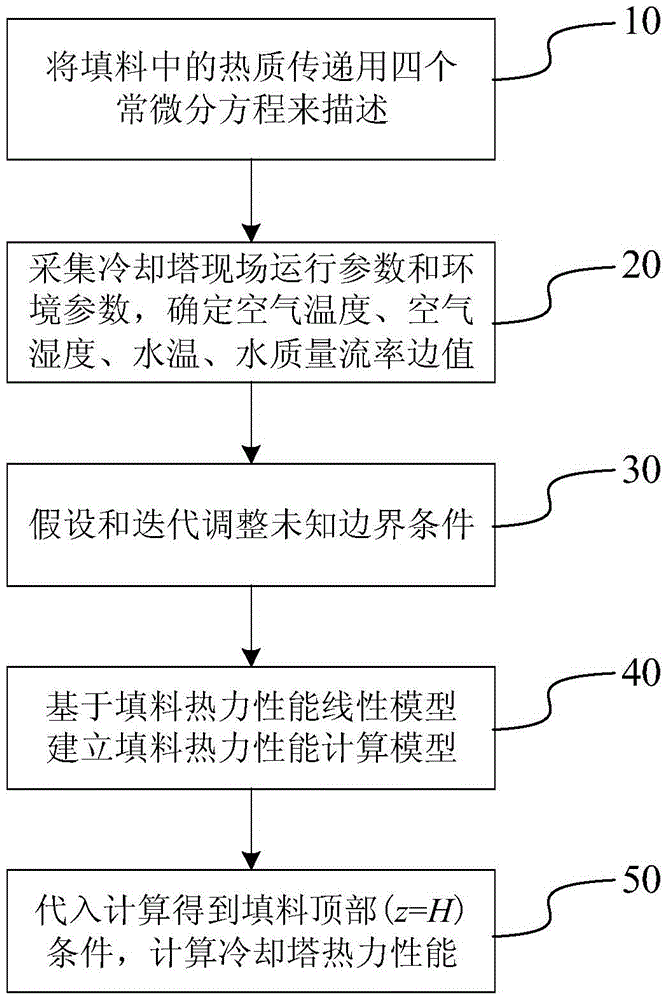

[0021] figure 1 It is a flowchart of a method for calculating the thermal performance of a cooling tower filler according to an embodiment of the present invention, and the method includes the following steps:

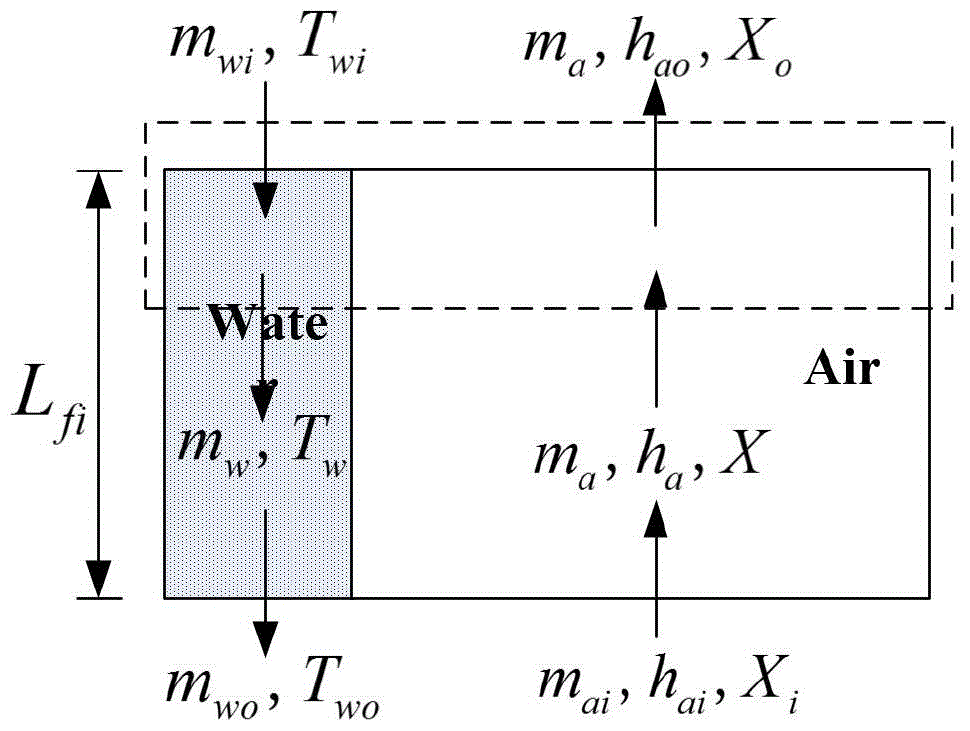

[0022] Step 10 describes the heat and mass transfer in the packing with a set of four ordinary differential equations for solving the derivative of the unknown function in the following form:

[0023]

[0024]

[0025]

[0026]

[0027] The four known conditions can be summarized as:

[0028] T a (z=0)=T ai

[0029] X(z=0)=X i

[0030] T w (z=H)=T wi

[0031] m w (z=H)=m wi

[0032] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com