A method of sewing linen clothes

A technology of hemp material clothing and material clothing, applied in the direction of sewing tools, etc., can solve problems such as unqualified sloppyness, achieve the effect of clean overall effect and avoid sloppyness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The hemp fabric is cut into a cut piece A1 and a cut piece B2, and the sewing process of the cut piece A1 and the cut piece B2 is as follows:

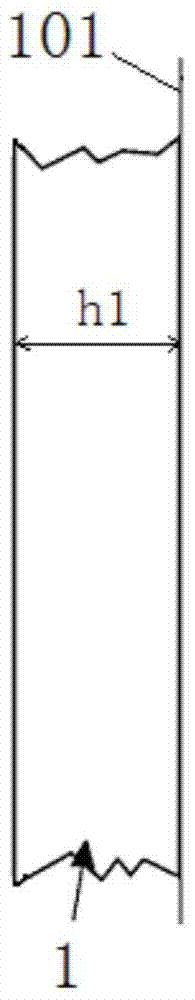

[0046] figure 1 It is a structural schematic diagram of cut sheet A in the present invention; as figure 1 As shown, the lining strip A is hot-bonded on the cutting piece A1, the lining strip A is aligned with the edge 101 of the cutting piece A, and the width h1 of the lining strip A is 2cm.

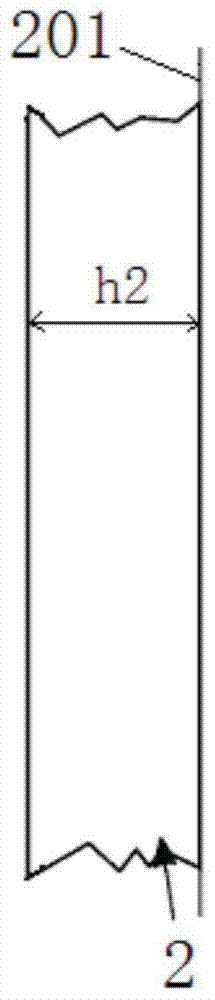

[0047] figure 2 It is a structural schematic diagram of the cut piece B in the present invention; as figure 2 Iron-on adhesive strip B on piece B2 as shown. The strip B is aligned with the edge 201 of the cut piece B, and the width h2 of the strip B is equal to the width h1 of the strip A, that is, h1=h2=2cm.

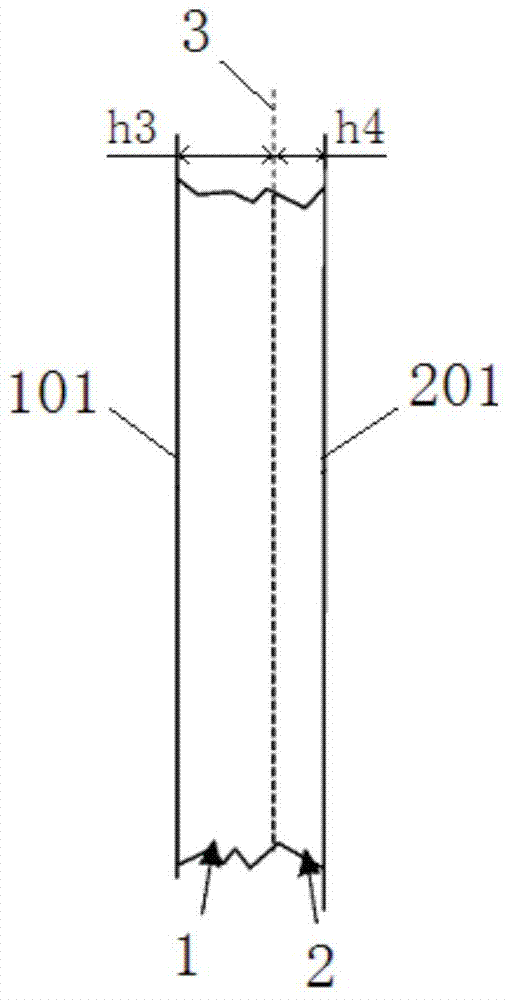

[0048] image 3 It is a schematic diagram of the stitching connection of the panel A and the panel B in the present invention; as image 3 As shown, the cut piece A1 and the cut piece B2 are stitched together by the seam lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com