Multifunctional self-locking wrench

A multi-functional, self-locking technology, used in wrenches, pliers, manufacturing tools, etc., can solve problems such as damage to the shape of the nut, large damage to the screwed object, and inability to screw the nut of a tubular object.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, by describing embodiment, the present invention will be further described:

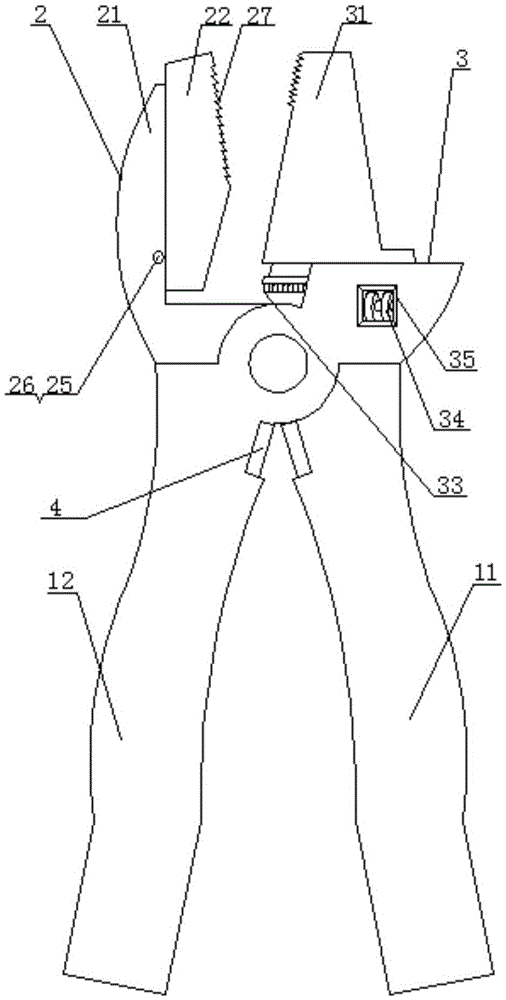

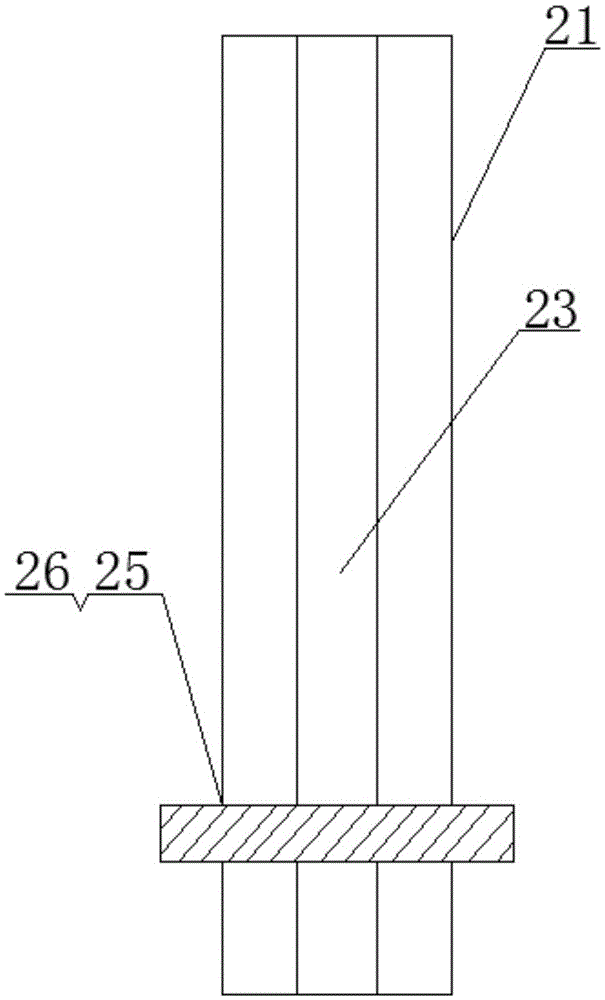

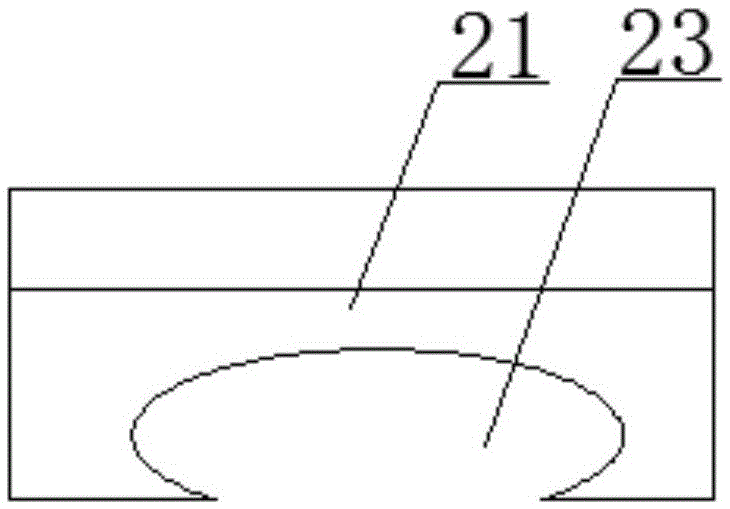

[0022] Such as Figures 1 to 4 As shown, a multifunctional self-locking wrench of the present invention includes a handle, and the handle includes two first handles 11 and second handles 12 that are mutually rotatably connected. The tops of the first and second handles 11 and 12 are respectively provided with first, Two clamping parts 2, 3, the first clamping part 2 is located above the second handle 12, the second clamping part 3 is located above the first handle 11, and the first clamping part 2 includes a vertical fixed claw 21 and The slider I22 on the fixed claw 21 is provided with an elliptical chute I23 along the vertical direction on the side of the fixed claw 21 facing inward, and the top and bottom of the slider I22 are provided to slide in the chute I23 The blocking block 24, the sliding block I22 and the fixed claw 21 are slidably con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com