Triaxial rotating work platform for optical element detection

A technology of three-axis rotation and working platform, which is applied in the direction of workbench, measuring device, manufacturing tools, etc., can solve the problems such as the inability to adjust the detection direction, the complete detection of difficult workpieces, and the easy occurrence of detection blind spots, etc., to achieve simple structure, convenient reading, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

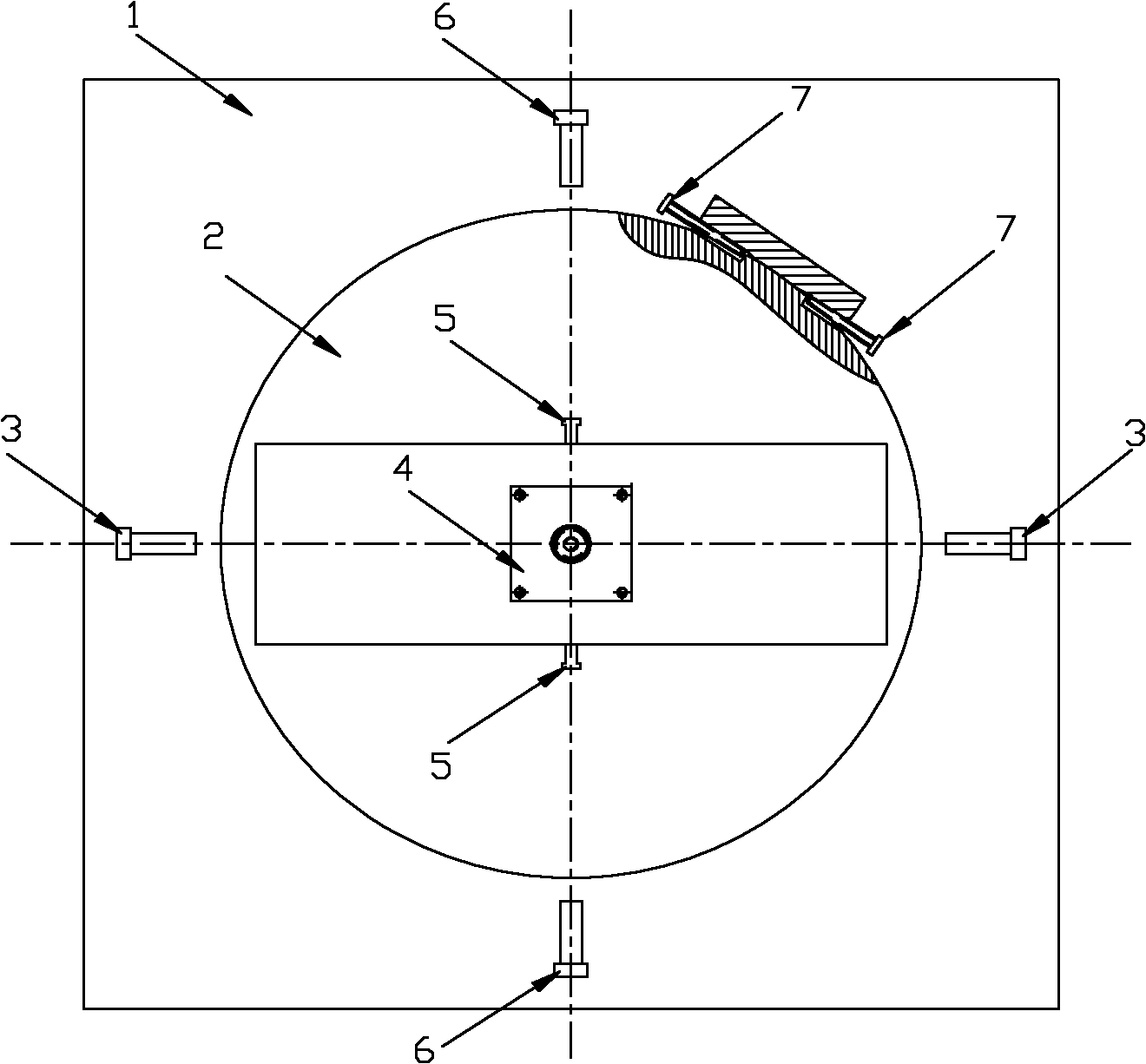

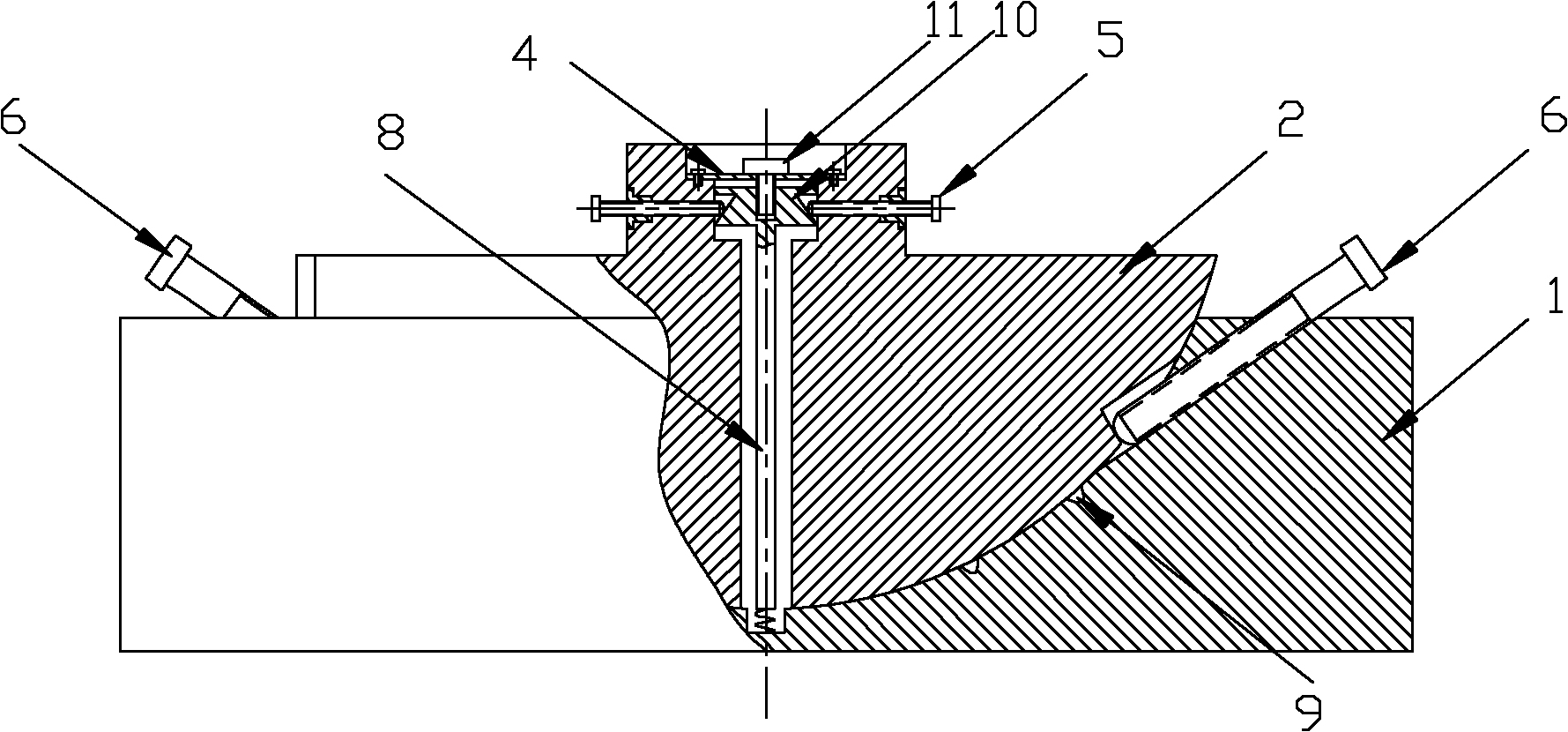

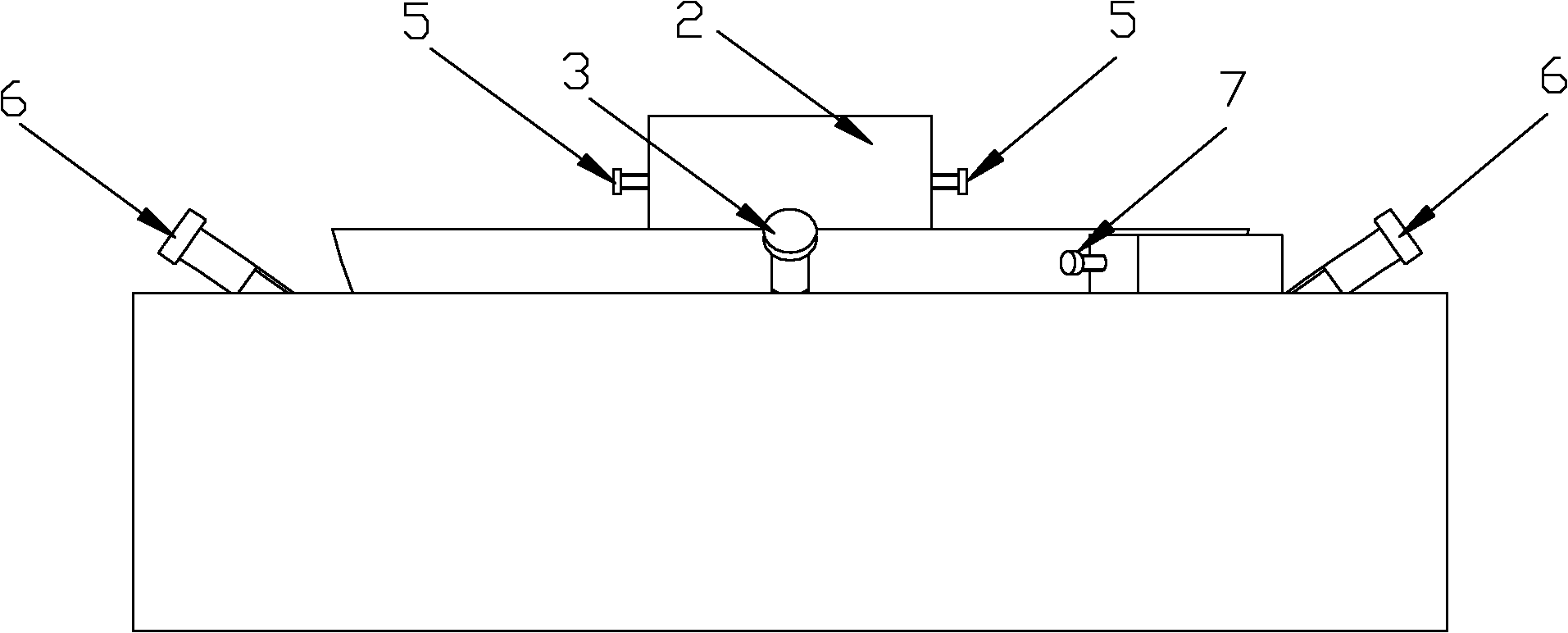

[0014] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0015] Such as Figure 1~4 As shown, the embodiment of the present invention is provided with a workbench 2, a base 1, a workbench inclination adjustment mechanism and a workbench fastening mechanism.

[0016] The upper surface of the workbench 2 is a workbench plane for placing the workpiece to be measured, the lower surface of the workbench 2 is installed on the groove on the base 1, and the lower surface of the workbench 2 can slide freely in the groove; There are 2 oil grooves in the groove of the base 1, which are used to store the lubricating oil required for the rotation of the workbench; the inclination adjustment mechanism of the worktable is provided with 6 positioning bolts, and the positioning bolts are fixed on the On the screw hole, withstand the groove of the sphere at the lower part of the table 2, and push the plane of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com