An automatic negative pressure adsorption manipulator

A manipulator and adsorption technology, applied in the field of manipulators, can solve the problems of destroying the surface shape of parts, destroying the shape and structure of parts, and unstable clamping force, etc., to achieve the effect of increasing the contact area, lifting objects, and protecting them from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

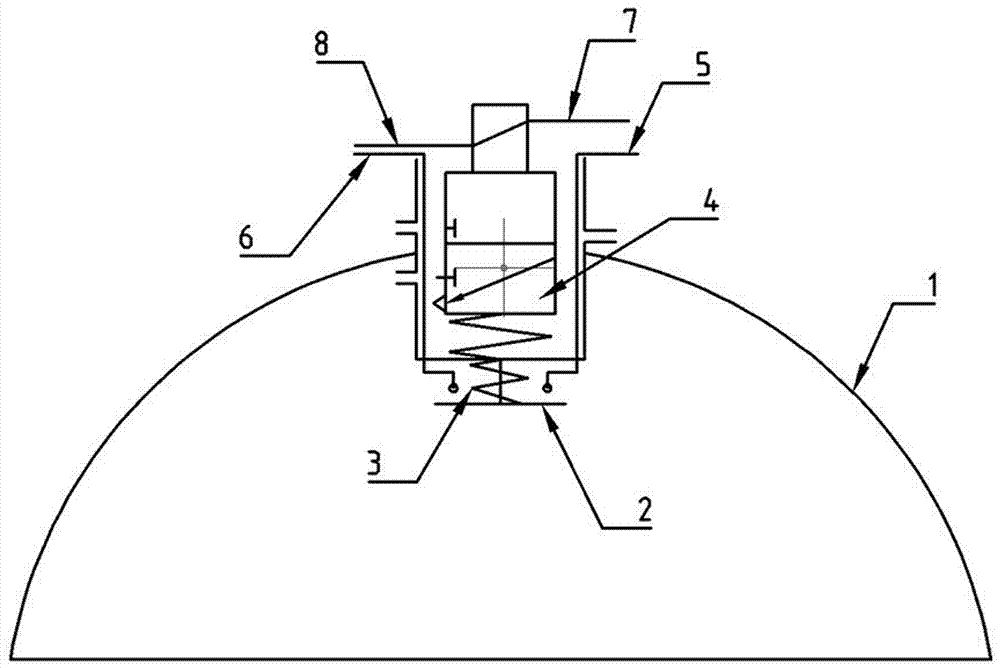

[0014] Such as figure 1 As shown, an automatic negative pressure adsorption manipulator of the present invention is composed of a plastic suction cup, a two-position three-way solenoid valve arranged in the center of the top of the suction cup, and a trigger shrapnel. The plastic suction cup is connected with the two-position three-way solenoid valve to form an air path , the two sides of the two-position three-way solenoid valve are provided with the first contact connection line and the second contact connection line respectively connected to the first solenoid valve joint and the second solenoid valve joint, and the trigger shrapnel is connected to the two-position three-way through the spring The solenoid valve is connected, and is contacted and connected with the first solenoid valve joint and the second solenoid valve joint through contacts arranged on the first contact connection line and the second contact connection line respectively. The plastic suction cup is a defo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com