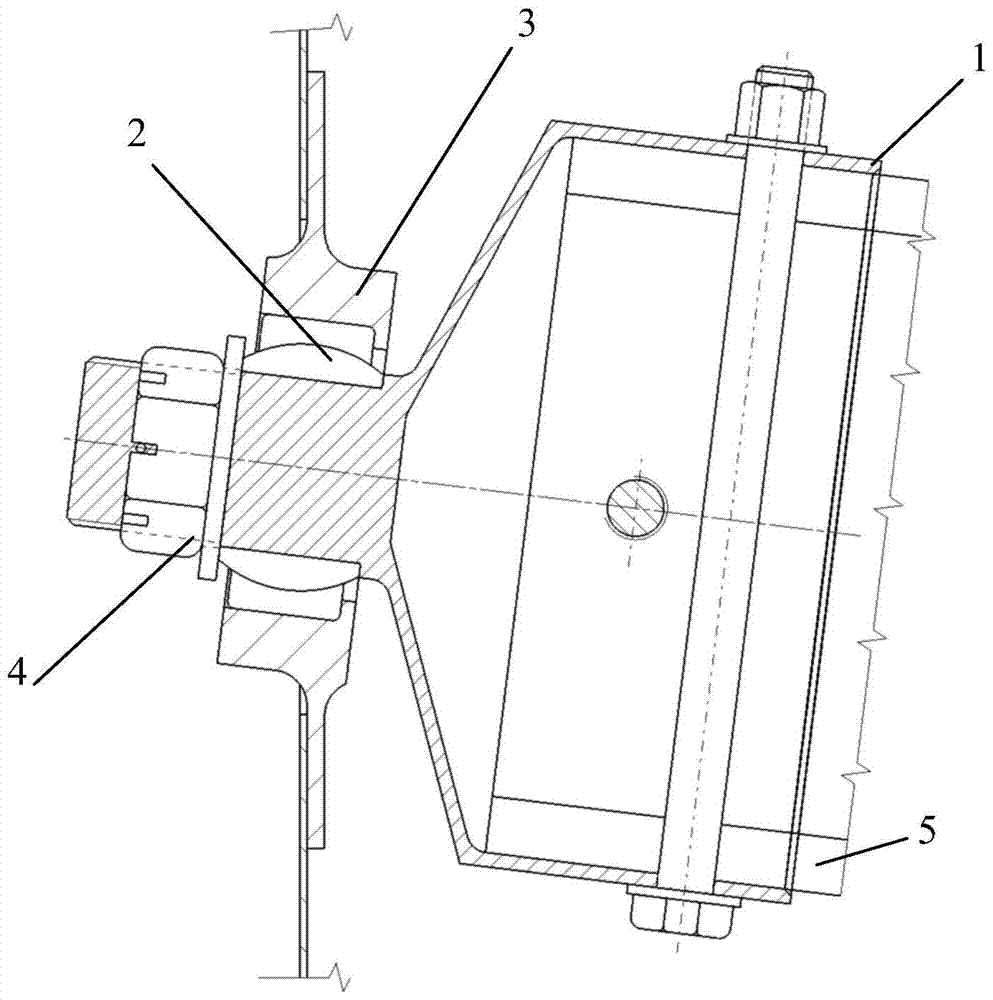

An Angle Adjustment Mechanism for Probing Rod at the Outer End of Wing

A technology of angle adjustment and probe rod, which is applied in the direction of aircraft parts, transportation and packaging, etc., can solve the problem that the equipment cannot be adjusted at any angle, and achieve the effect of small structure occupation, stable overall structure and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

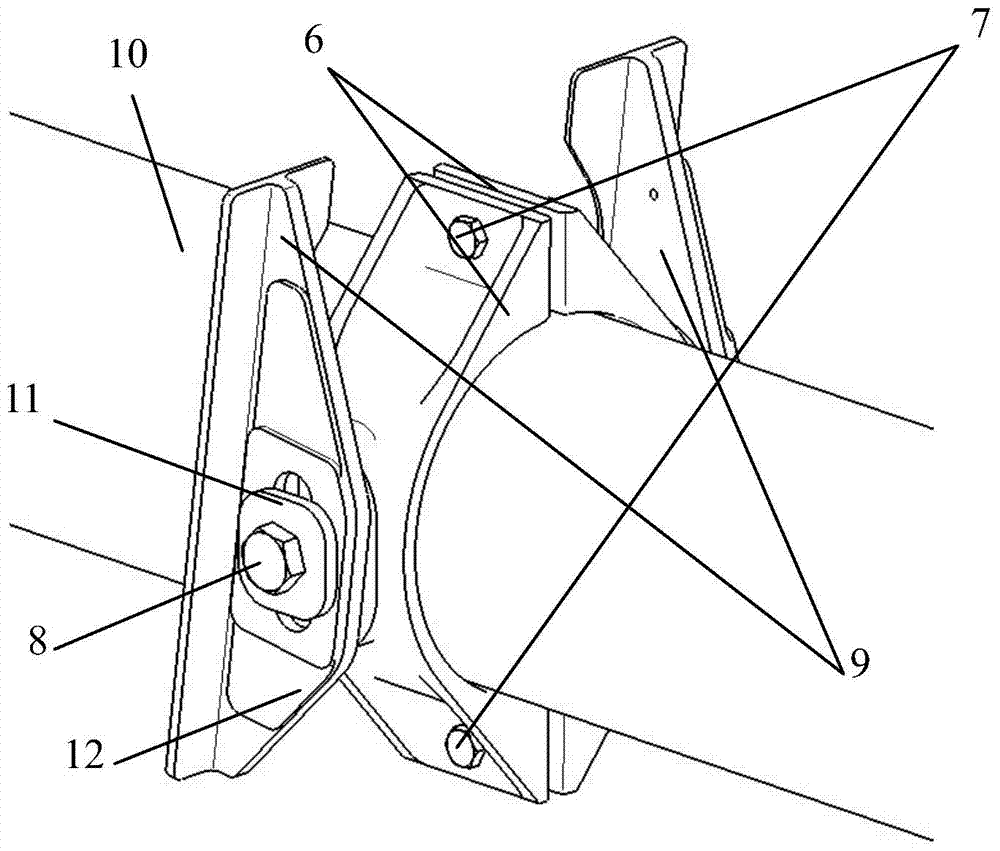

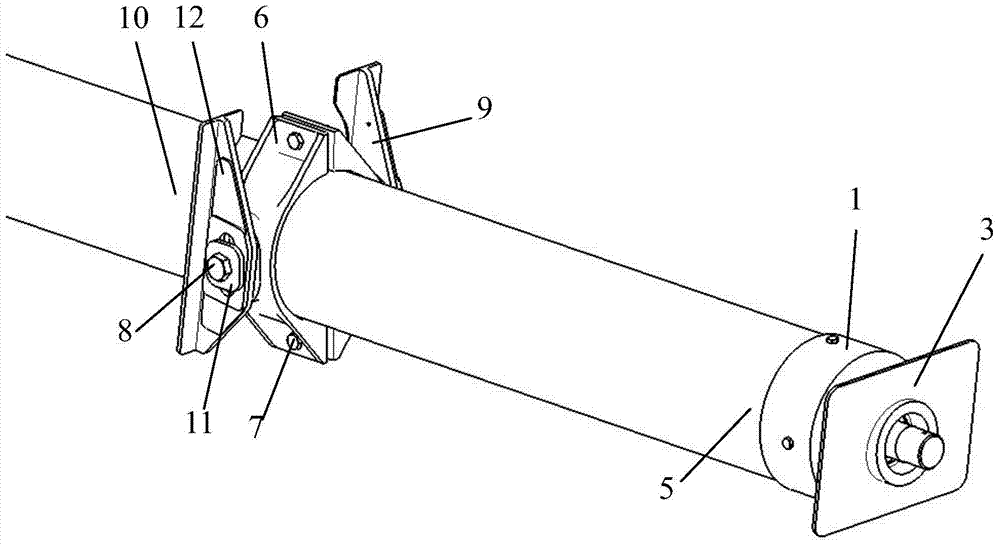

Embodiment 1

[0029] On the basis of specific implementation, the teeth of the toothed pad 11 and the tooth plate 12 are triangular teeth, and the tile cover 6 is semicircular. The movable space of the bolt II 8 processed on the bracket 9 and the tooth 12 is oblong when the probe rod is adjusted. L is 1 mm, R is 555 mm, and α is calculated to be 0.1°, that is, every time the toothed pad 11 and the tooth plate 12 move a sawtooth, the probe rod rotates 0.1°; when the middle part 10 of the probe rod is adjusted to a proper position, the lock Tighten the bolt II 8, the teeth of the toothed pad 11 and the tooth plate 12 are engaged, and the middle part 10 of the probe rod is limited, and the fixation of the probe rod after angle adjustment is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com