Water-in-oil drilling fluid and preparation method thereof

A water-in-oil type and drilling fluid technology, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor emulsion stability and high temperature resistance, and achieve good temperature and salt resistance, filtration loss Small amount, good emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

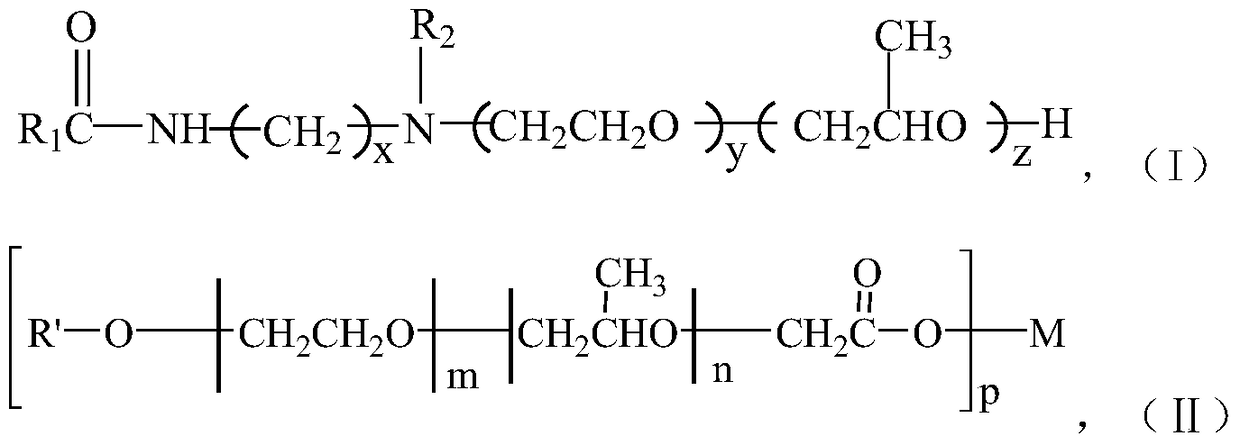

Method used

Image

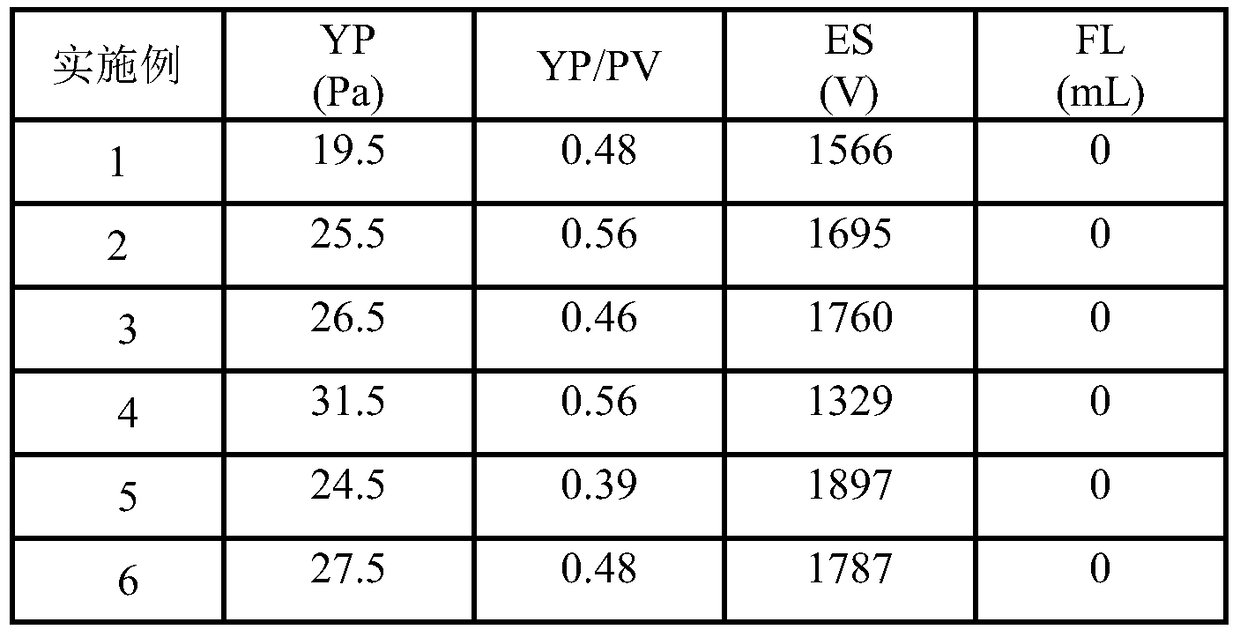

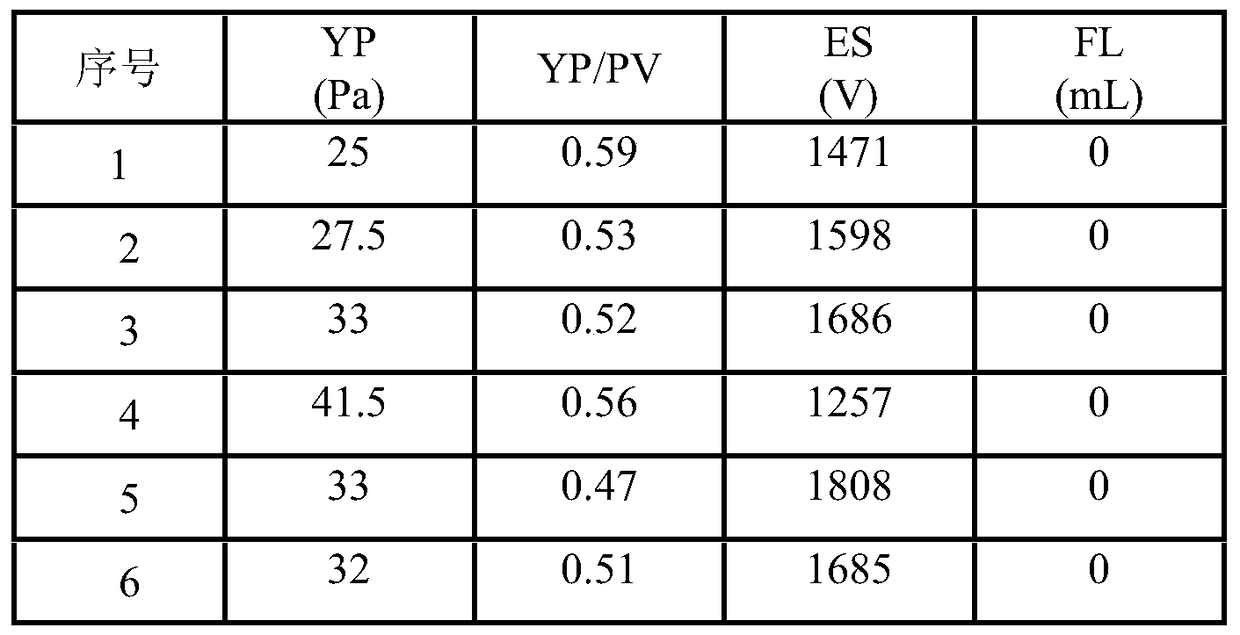

Examples

Embodiment 1

[0045] (a) Preparation of Lauroyl Hydroxyethylethylenediamine (x=2, y=1, z=0)

[0046] Add 17 parts of N-hydroxyethylethylenediamine and 1.75 parts of KOH into a reactor equipped with a sealed mechanical stirrer, a thermometer, a condenser tube, and a receiving bottle. After stirring at 120°C for 1 hour, slowly add lauric acid dropwise 35 parts of methyl esters were added dropwise within 1 hour. React at 155°C for 6 hours, the methanol generated in the reaction is collected into the receiving bottle through the condenser tube, and then the remaining low-boiling point products and reaction raw materials are distilled off under reduced pressure to obtain 39.7 parts of the target product lauroyl hydroxyethylethylenediamine .

[0047] (b) Preparation of oil-based drilling fluid compound emulsifier

[0048] In parts by mass, 50 parts of lauroyl hydroxyethyl ethylenediamine obtained in step (a), 5 parts of polyoxyethylene polyoxypropylene ether zinc acetate (m=4, n=15) and 5 parts...

Embodiment 2

[0057] (a) Preparation of Lauroyl Hydroxyethylethylenediamine (x=2)

[0058] Add 17 parts of N-hydroxyethylethylenediamine and 0.35 parts of KOH into a reactor equipped with a sealed mechanical stirrer, a thermometer, a straight condenser tube, and a receiving bottle. After stirring at 150°C for 1 hour, slowly add 70 parts of methyl laurate were added dropwise within 1 hour. React at 180°C for 16 hours, the methanol generated in the reaction is collected into the receiving bottle through a straight condenser, and the remaining low-boiling products and reaction raw materials are distilled off under reduced pressure to obtain the target product fatty acyl hydroxyethyl ethylenediamine .

[0059] (b) Synthesis of N, N'-dilauroyl hydroxyethyl ethylenediamine polyoxyethylene ether (y=5, z=0)

[0060] Add 70 parts of N, N'-dilauroyl hydroxyethyl ethylenediamine synthesized in step (a), 3.5 parts of calcium oxide and calcium hydroxide mixture (the weight ratio of calcium oxide and c...

Embodiment 3

[0066] (a) Synthesis of N, N'-bisstearyl hydroxyethyl ethylenediamine (x=2)

[0067] Add 49 parts of N-hydroxyethylethylenediamine and 2.7 parts of KOH into a reactor equipped with a sealed mechanical stirrer, a thermometer, a straight condenser tube, and a receiving bottle. After stirring at 145°C for 1 hour, slowly add 270 parts of methyl stearate were added dropwise within 1 hour. React at 165°C for 12 hours, and the methanol generated in the reaction is collected into a receiving bottle through a straight condenser. The remaining low-boiling products and reaction raw materials were distilled off under reduced pressure to obtain the target product N,N'-bisstearyl hydroxyethyl ethylenediamine.

[0068] (b) Synthesis of N, N'-distearoyl hydroxyethyl ethylenediamine polyoxypropylene ether (y=1, z=10)

[0069] 203 grams of N, N'-distearoyl hydroxyethyl ethylenediamine and 185.4 parts of propylene oxide under the action of 7.6 parts of calcium oxide and calcium hydroxide mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com