Soft plastic and hard sheet integrated injection-molded keyboard, keycap and production method

A technology of injection molding and soft rubber, applied in layers, emergency contact forms, emergency protection devices, etc., can solve the problems of troublesome assembly, high production cost, and difficulty in waterproofing and dustproofing, and achieve simple and convenient assembly, low cost, The effect of force balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

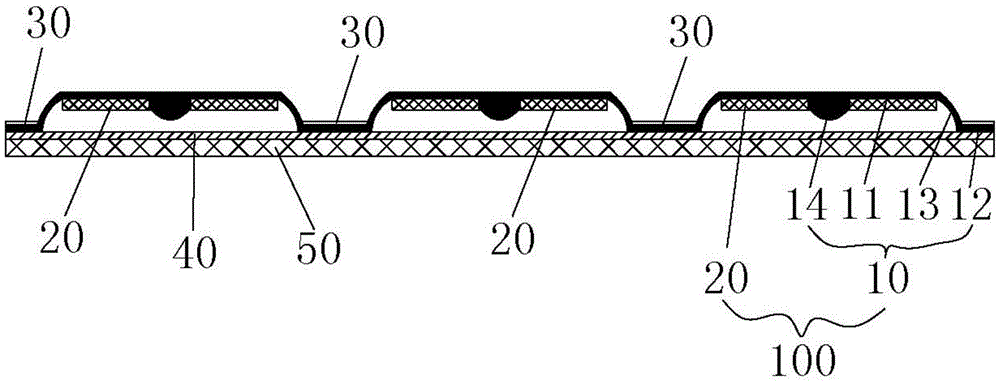

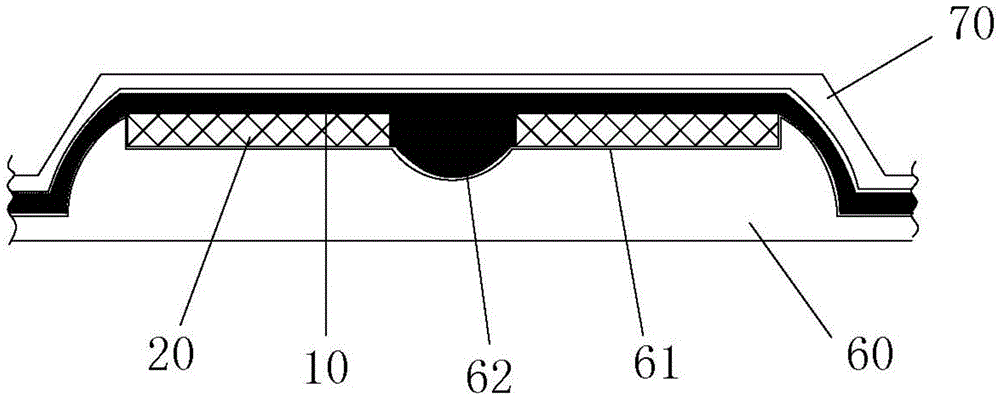

[0030] Such as Figure 1-4 As shown, a kind of soft rubber 10 and hard sheet 20 of the present invention are integrally injection-molded keyboards, the keyboard is only composed of soft rubber 10 and hard sheet 20, an integrated keycap 100, a button grid bracket 30, and an integrated The printed circuit film 40 under the type key cap 100 and the keyboard bottom plate 50 supported under the printed circuit film 40;

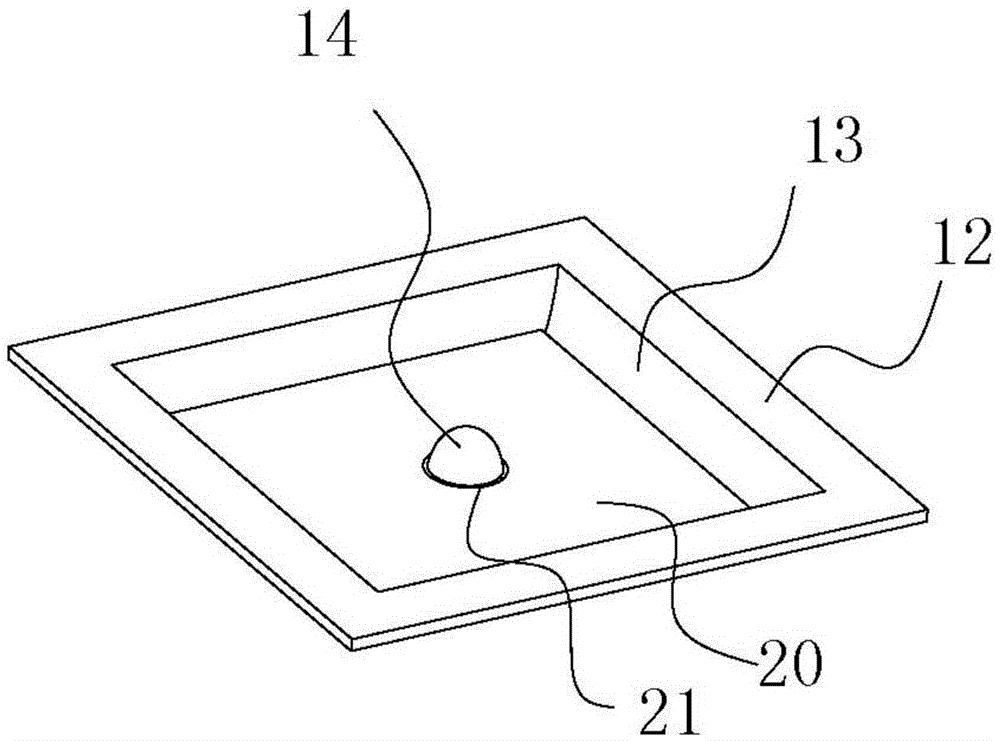

[0031] The integrated key cap 100 composed of the soft rubber 10 and the hard sheet 20 is composed of several adjacent soft rubber key surfaces 11, a hard sheet 20 bonded to the soft rubber key surface 11, a soft rubber base 12, The soft rubber supporting body 13 connecting the soft rubber base 12 and the soft rubber key surface 11 and the soft rubber key surface 11 penetrates the through hole 21 of the hard sheet 20 downwards and is connected with the bottom surface of the soft rubber key surface 11 as a whole The convex elastic switch body 14 is composed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com