Fixing seat for aviation storage battery

A technology for aviation batteries and fixing bases, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of insufficient firmness and strength of convex and concave structures, no double safety protection measures, and insufficient structural strength and reliability, and achieve large The effect of safety and reliability, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The mode of work and the manufacture method of this design invention:

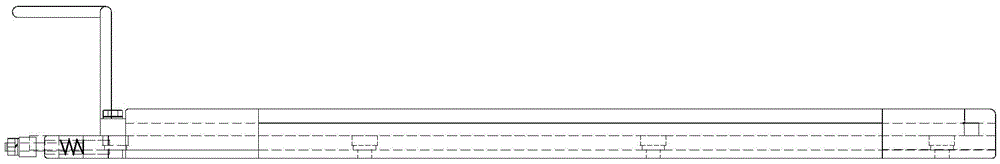

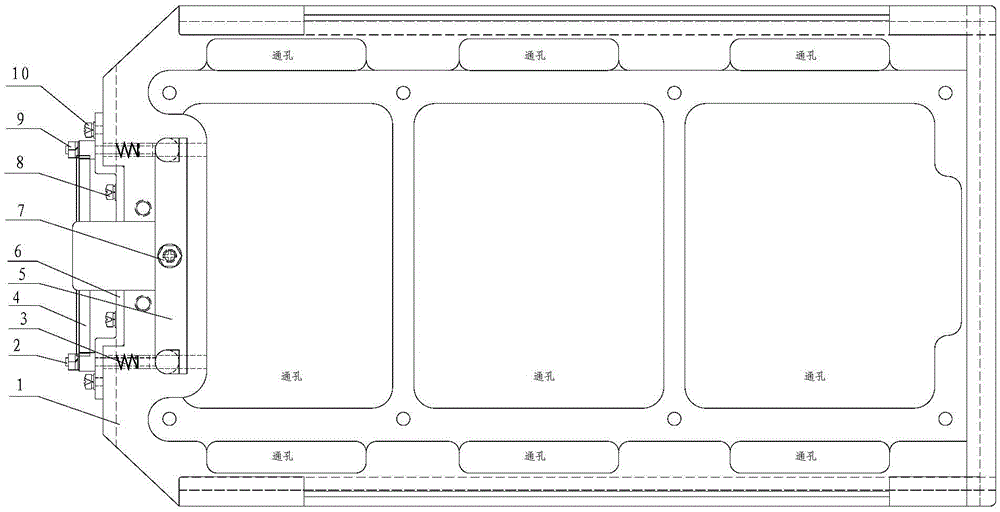

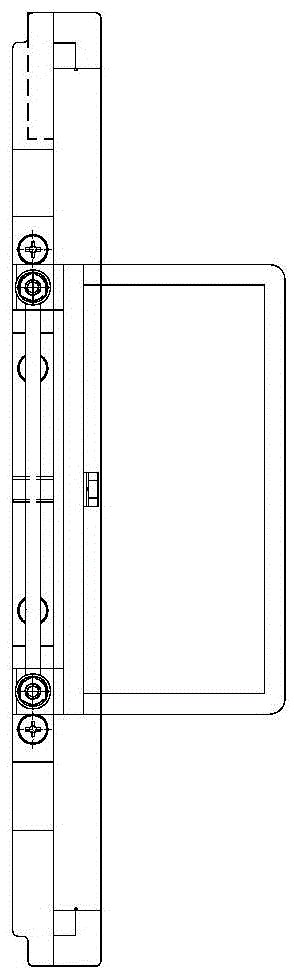

[0042] Such as figure 2 As shown, in order to ensure high reliability and safety, this design invention adopts box flash and figure 1 The sliding way of the fixed seat is fitted and disassembled through the locking mechanism of the spring lock lever, which constitutes a double safety assembly relationship and is convenient for operation, use and maintenance.

[0043] Under the premise of ensuring the reliability and rationality of the structure, this design invention mainly adopts the overall milling process to remove the remaining material for the processing of the base of the part 1. On the premise of ensuring sufficient strength, the part 1 is designed as followsfigure 1 The structure shown is the multi-directional symmetrical and simple structural design of the layered and frame-cooperated slideway. Specifically, through the three-layer design, the bottom of the 8 mounting holes is designed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com