Manufacturing method of invisible orthodontic braces and invisible orthodontic braces

A production method and invisible orthodontic technology, which is applied in orthodontics, dentistry, dental restoration, etc., can solve the problems of high price of invisible aligners, inability to perform orthodontics, and difficulty in cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the purpose, features and effects of the present invention, now through the following specific embodiments, and in conjunction with the accompanying drawings, the present invention is described in detail, as follows:

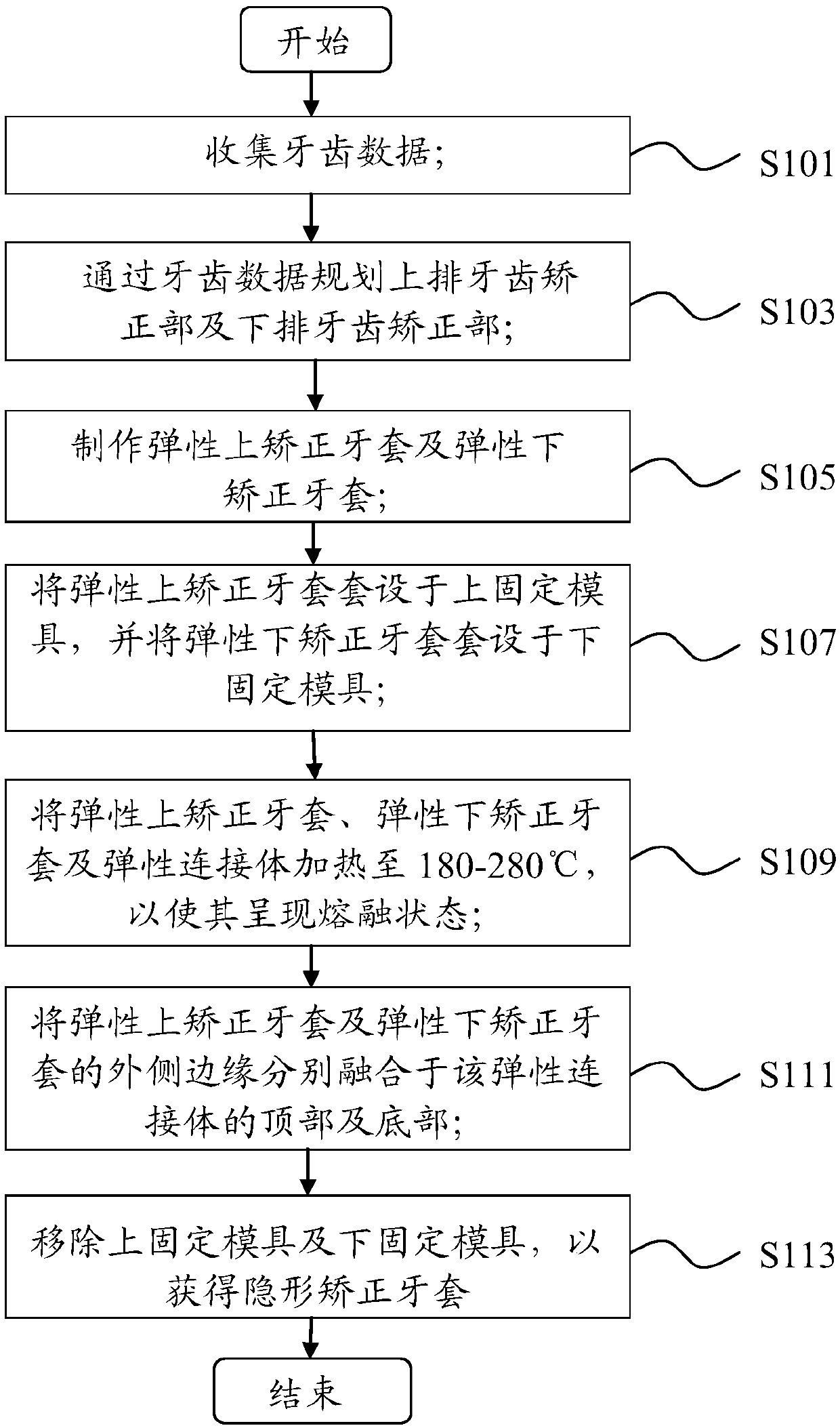

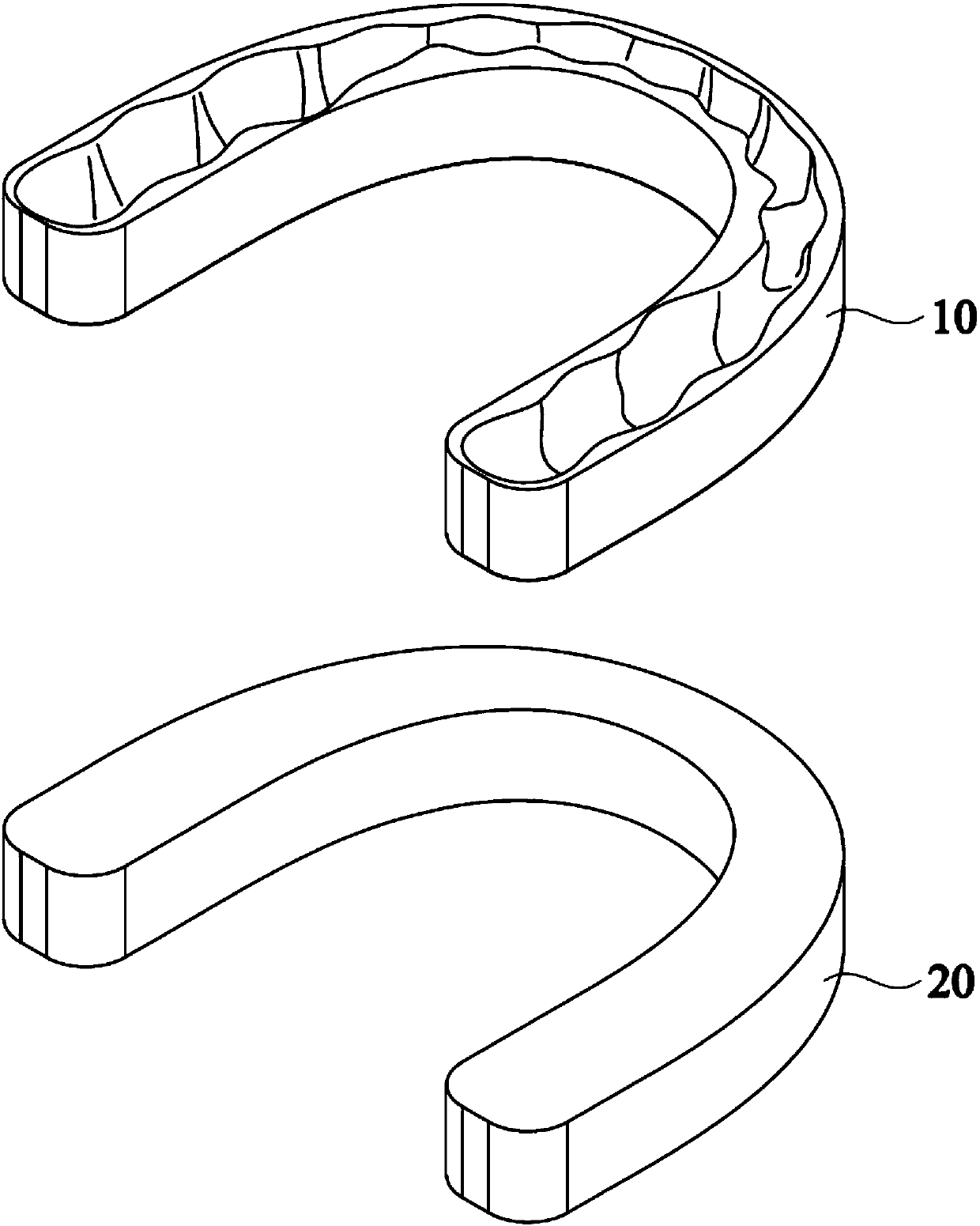

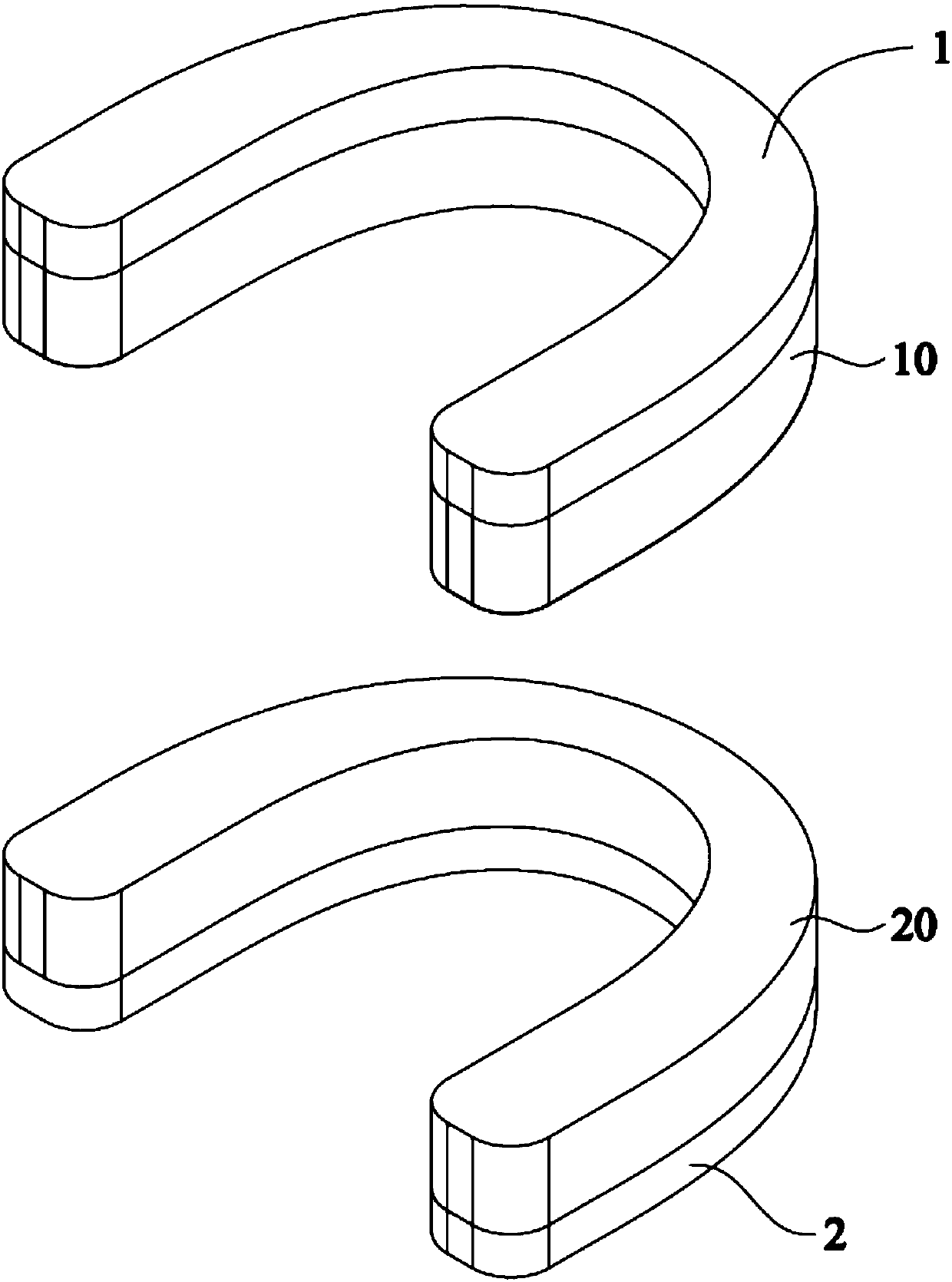

[0030] refer to figure 1 , is a flowchart of the manufacturing method of the invisible orthodontic braces of the present invention, and the manufacturing method includes seven steps. Below, will be figure 1 , Figure 2a to Figure 2e With a text description to illustrate the production method.

[0031] First, if figure 1 As shown, in step S101, the dental data of the user is collected, for example, the user's oral photos, scan files, bite records, etc. are usually collected.

[0032] Next, if figure 1 As shown, in step S103, the upper row of orthodontics and the lower row of orthodontics are planned through the tooth data; more specifically, the computer is used to analyze the dental data, and plan the user’s upper teeth a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com