Convenient-to-use recording pen assembly for connecting electric fusion pipe

A recording pen and electrofusion tube technology, which is applied in the direction of using mechanical devices, measuring devices, instruments, etc., can solve the problems of inconvenient use and low precision of recording pen components, so as to save the need to replace recording pen and operate recording pen, and record accurate recording. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

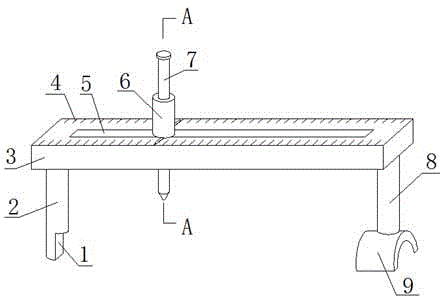

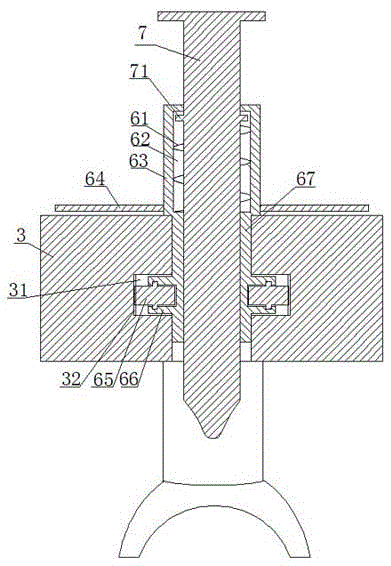

[0020] Such as figure 1 , figure 2 As shown, an easy-to-use recording pen assembly for connecting an electrofusion tube includes a scale plate 3 engraved with a scale bar 4, and the lower sides of the two ends of the scale plate 3 are respectively provided with a clamping device and a positioning device, and the clamping device It includes a clamping column 2 connected to the scale plate 3, and the lower end of the clamping column 2 is provided with a bayonet 1. The positioning device includes a connecting column 8 connected to the scale plate 3, and a curved soft rubber pad is connected to the lower end of the connecting column 8. 9. The middle part of the scale plate 3 is also provided with a chute 5 along the length direction of the scale plate 3, and a sliding sleeve 6 is arranged in the chute 5, and the sliding sleeve 6 includes a guide block 67 arranged in the chute 5 and connected to the The positioning column 63 on the upper end of the guide block 67, the positioning...

Embodiment 2

[0026] This embodiment adds the following structure on the basis of the above-mentioned embodiment 1: the scale bar 4 is provided with two rows, respectively arranged on both sides of the chute 5, and the scale bars 4 of the two rows are all along the length of the scale plate 3 Orientation is set uniformly.

[0027] In this embodiment, by arranging two rows of scale bars 4, the staff can read from any row of scale bars 4 when marking the line, avoiding the problem that the normal reading cannot be performed due to the influence of the work site and position, and the reading is more convenient.

Embodiment 3

[0029] In this embodiment, the following structure is added on the basis of Embodiment 2: two scale indicator bars 64 corresponding to the scale bar 4 are arranged on the circumference of the positioning column 63 , and the scale indicator bars 64 are arranged perpendicular to the chute 5 .

[0030] In this embodiment, the scale indicating bar 64 moves with the sliding of the sliding sleeve 6 , and corresponds to the scale bar 4 , which facilitates the reading of values through the scale indicating bar 64 and improves the recording accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com