Positioning clamp

A positioning clamping and positioning plate technology, applied in the direction of clamps, manufacturing tools, etc., can solve the problems of time-consuming and laborious, troublesome disassembly and assembly of plates, and movement, and achieve the effect of preventing movement, disassembly and assembly, and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

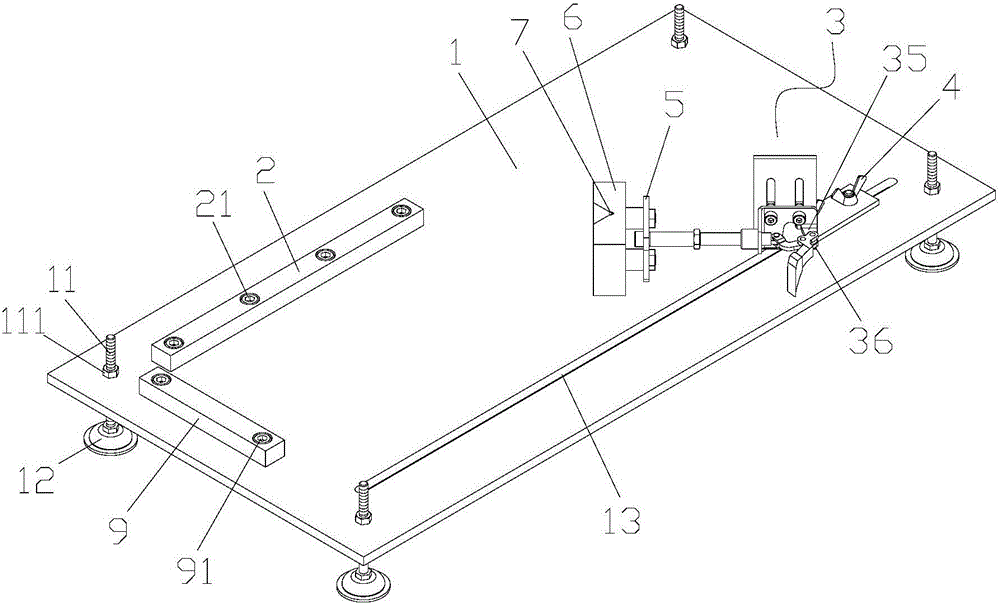

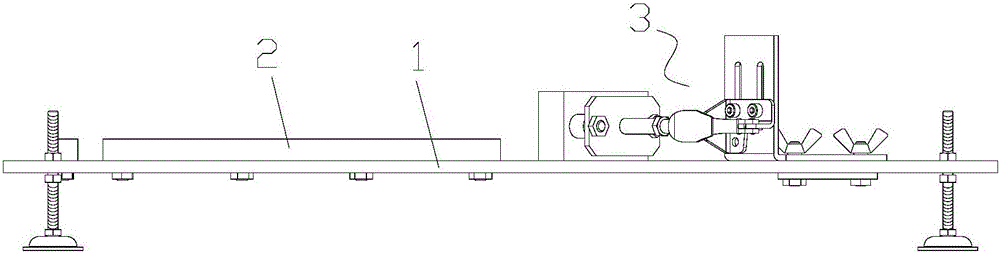

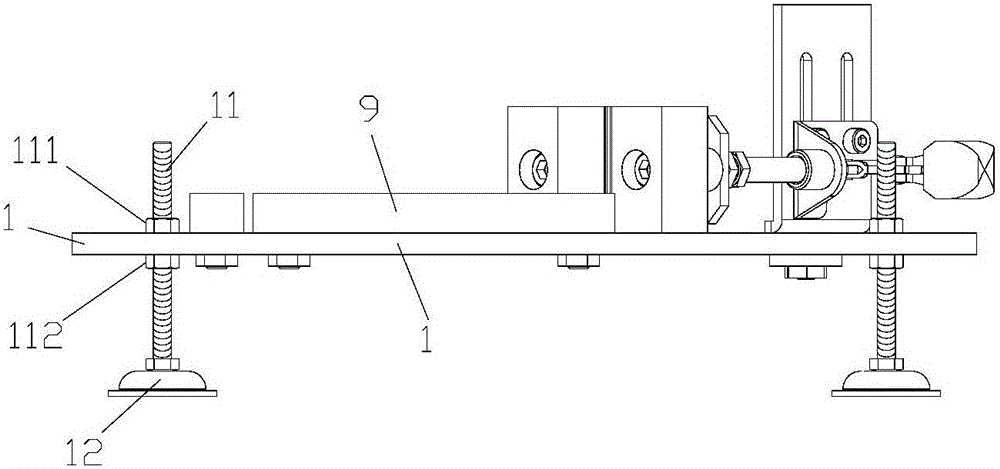

[0026] Such as Figure 1-Figure 5 As shown, the positioning clamp includes a bottom plate 1, the bottom plate 1 is a cuboid structure, and threaded holes are processed at the four corners of the bottom plate 1, and the threaded holes penetrate from the upper surface of the bottom plate 1 to the bottom of the bottom plate 1 surface. Support screw rod 11 is installed in each threaded hole, and support base 12 is vertically installed on the lower surface of each support screw rod 11, and the lower surface of support base 12 is planar structure, and described support screw rod 11 passes threaded hole, and Each support screw 11 is threadedly equipped with a tightening nut A111 and a tightening nut B112, the lower surface of the tightening nut A111 is against the upper surface of the bottom plate 1, and the upper surface of the tightening nut B112 is against the upper surface of the base plate 1. The lower surface of the base plate 1 is fixed on the base plate 1 by the support scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com