A high-frequency longitudinal-torsion composite vibrating sponge array strip-taking device and its application

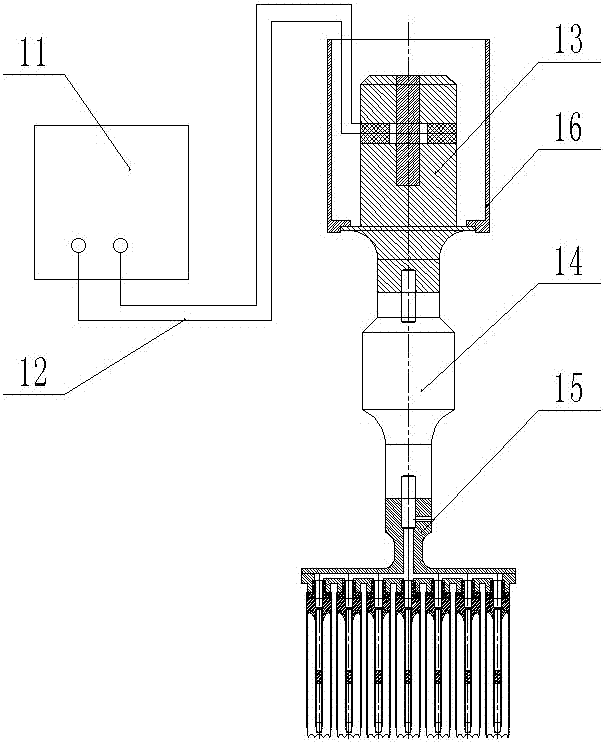

A compound vibration and longitudinal torsion technology, which is applied in metal processing and other directions, can solve the problems of inability to process multiple pieces at the same time, difficult strip control, low efficiency, etc., and achieve the effect of expanding the scope of use, broad market prospects, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

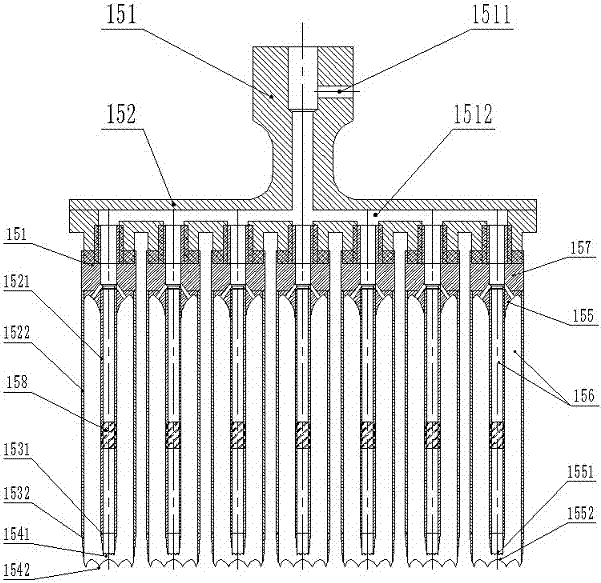

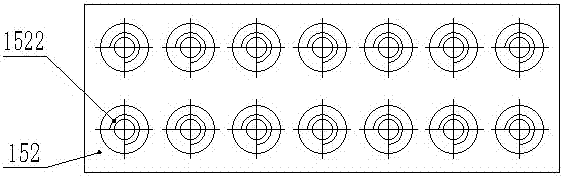

[0046] Such as figure 2 and image 3 As shown, the multi-tube cutter 15 includes a connecting head 151 connected to the horn 14, a pipe body mounting plate 152 connected to the connecting head 151, and an internal cavity 156 is set on the pipe body mounting plate 152 The inner layer tube body 1521 and the outer layer tube body 1522, the inner cutting edge 1531 and the outer cutting edge 1532.

[0047] Continue to see figure 2 and image 3 One end of the inner tube body 1521 and the outer tube body 1522 containing the cavity 156 is threadedly connected with the tube body installation plate 152, and the other end is welded to the inner cutting edge 1531 and the outer cutting edge 1532, and the inner layer The inner diameter of the tube body 1521 is 5 mm, the inner diameter of the outer layer tube body 1522 is 12 mm, the tube walls of the inner layer tube body 1521 and the outer layer tube body 1522 are both 1 mm, and the materials of the inner layer tube body 1521 and the o...

Embodiment 2

[0060] The difference from Embodiment 1 is that the tube body mounting plate 152 also includes a cover 1523 for the internally threaded hole 1522 . It is used for the closure of the internally threaded hole 1522 that is not connected to the pipe body 156 .

[0061] For example, when the inner and outer diameters of the pre-processed cylindrical hollow strip blank are relatively large, such as Figure 7 As shown, the external thread head 1533 of the pipe body 156 matches the internal thread hole 1522, and the cavity 153 matches the size of the pre-processed hole.

[0062] Since the outer diameter of the tube becomes larger, the tubes cannot be sequentially arranged on the tube mounting plate 152 , and the unused internal threaded hole 1522 is closed by the cover 1523 .

[0063] Using the processing process described in Embodiment 1, the processing of multiple cylindrical hollow strip blanks 23 can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com