Universal type elastic potential energy mechanical catapult for single tandem wing unmanned aerial vehicle with rear propeller

A potential energy machine and propeller technology, which is used in the field of assisted take-off of fixed-wing unmanned aerial vehicles, can solve the problems of rising quality, large size, and inability to use landing gear, etc., and achieves the effect of easy use, regular shape, and extensive support and adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

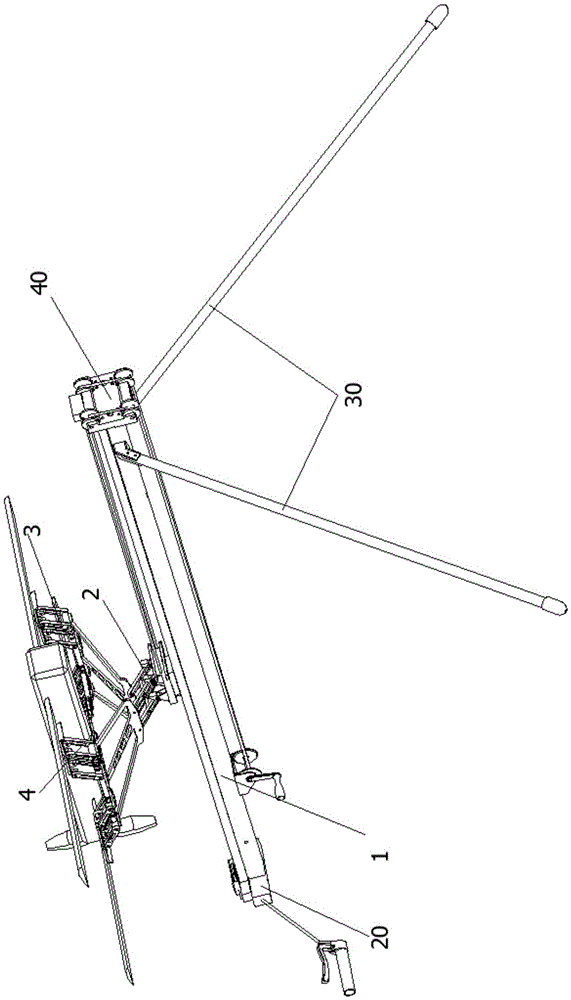

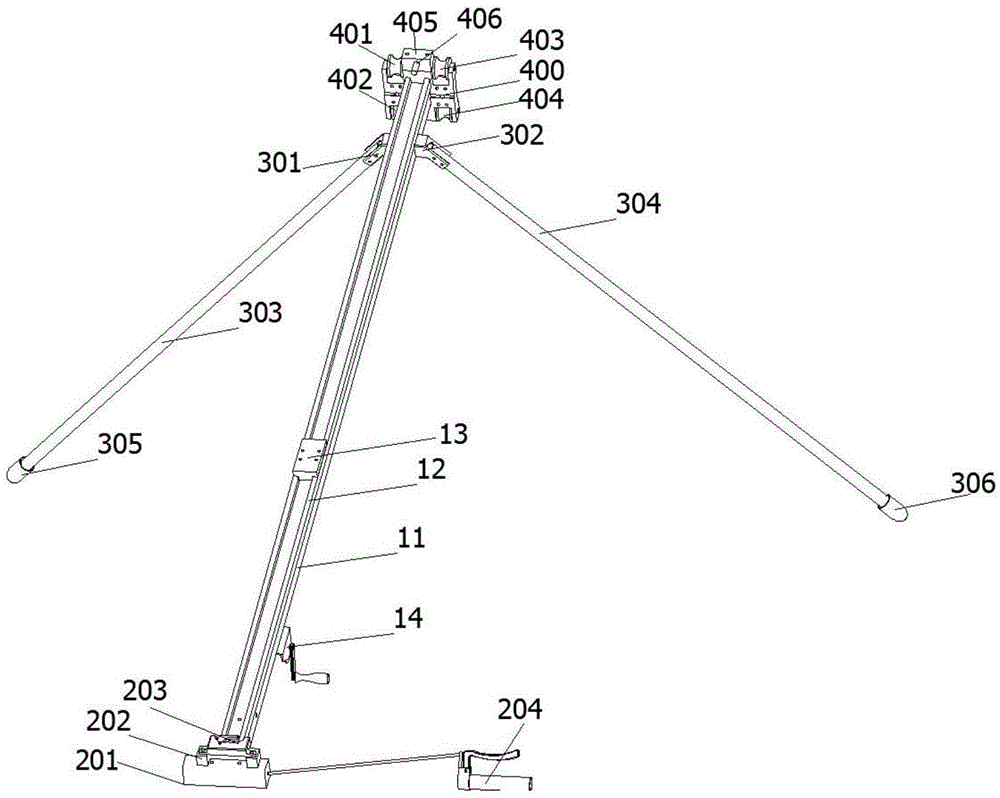

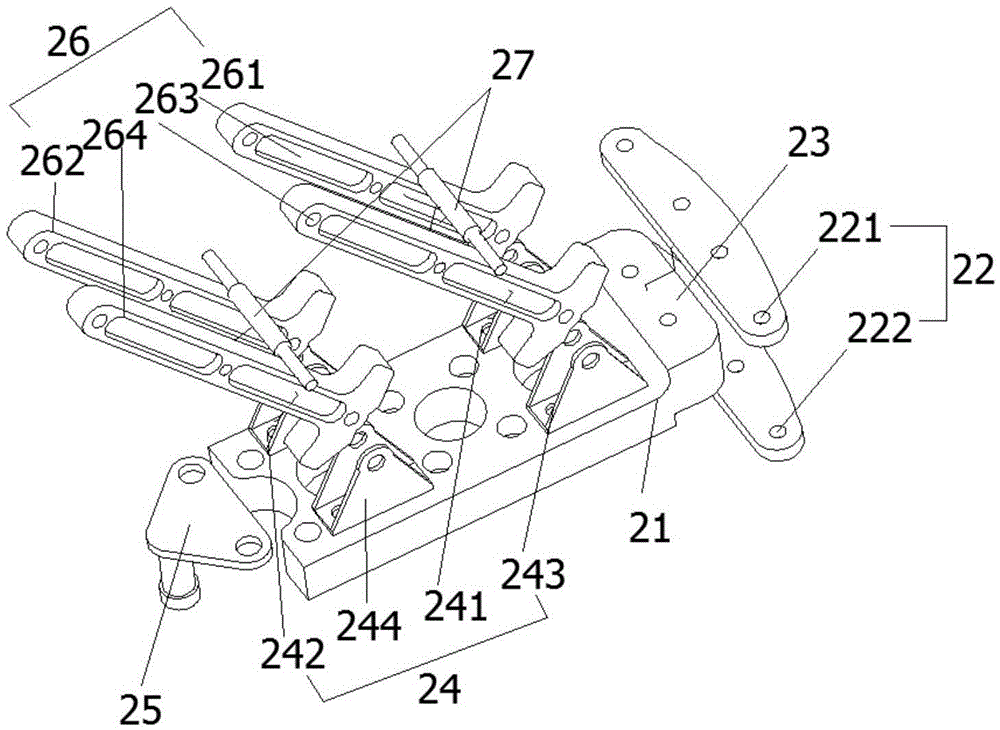

[0028] Such as figure 1 and figure 2 As shown, the structural schematic diagram of the present invention includes a body 1, a launch frame assembly 2, a projectile expansion device 3 and an aircraft body structure reinforced projectile assembly 4; A plurality of series-connected slide rails 12 are installed on the base frame 11, low rolling resistance sliders 13 are embedded in the slide rails 12, a winch 14 is installed at the bottom of the body 1, and a catapult switch is installed at the end of the body 1 Assemblies 20, support rod assemblies 30 are installed on both sides of the body 1, and the head end of the body 1 is installed with a roller shock absorber retainer assembly 40; the ejection frame assembly 2 is fixed on the slider 13; the ejection expansion device 3 is hinged on the ejection frame assembly 2 Above, an aircraft is installed on the projectile expansion device 3; the aircraft body structure reinforced projectile assembly 4 includes a body reinforcement con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com