Aerosol tank for detecting air purifier

A kind of air purification equipment and aerosol technology, applied in the field of aerosol cabin, can solve the problems of construction quality influence, uneven surface finish of inner cabin, long construction time, etc., and achieve high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

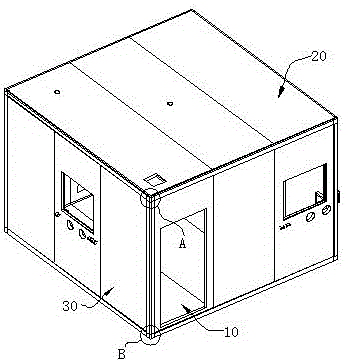

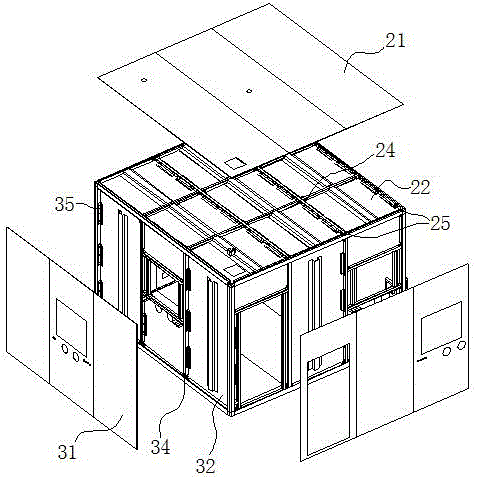

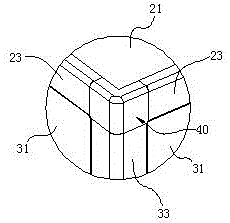

[0034] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8 are an inventive aerosol chamber for detecting air purification equipment, which is a hexahedral structure composed of a bottom frame 10, a side plate assembly 30, and a top plate assembly 20 A top connector 40 is provided at the top four corners of the aerosol cabin, and a bottom connector 50 is respectively arranged at the four corners of the bottom, wherein the chassis 10 includes four bottom beams 13, The plastic plate 11 and the stainless steel plate 12 attached to the plastic plate 11, the inner side of the bottom beam 13 is provided with a first vertical surface 131 extending upward from the lower surface of the bottom beam 13, and a first vertical surface 131 extending from the top of the first vertical surface 131 to the air. The first horizontal overlapping surface 132 extending inside the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com