Vibration mechanism, receiver and assembly method of receiver

An assembly method and technology of vibration mechanism, applied in the direction of sensors, electrical components, etc., can solve the problems of low reliability of vibration mechanism and difficult assembly, and achieve high strength, ensure normal installation, and high connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

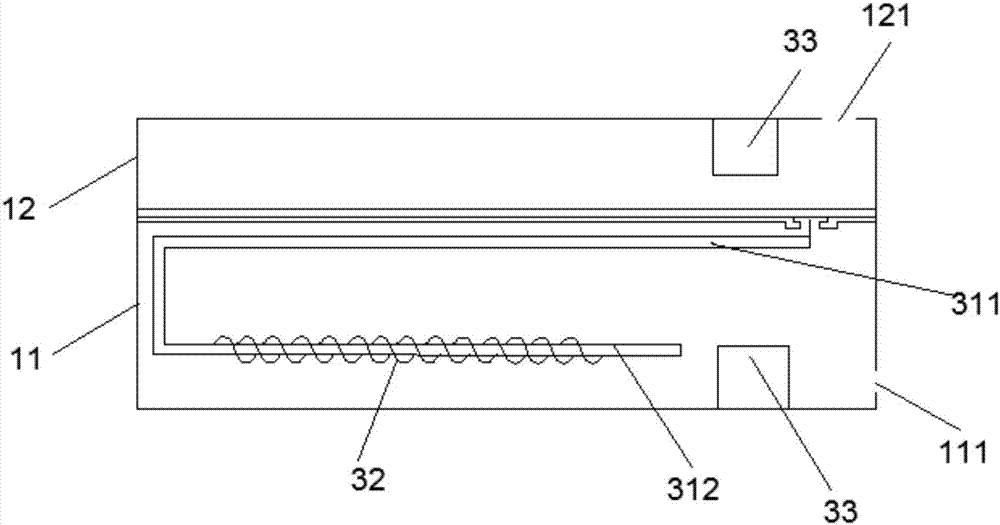

[0061] This embodiment provides a receiver, such as image 3 As shown, it includes a housing 1 , a sound membrane mechanism 2 and a vibration mechanism 3 . The housing 1 has a first housing 11 formed with a first chamber 13 and a second housing 12 formed with a second chamber 14, the first housing 11 and the second housing 12 can be buckled to form an inner chamber , wherein the first housing 11 is provided with a tuning hole 111 , and the second housing 12 is provided with a sound outlet 121 .

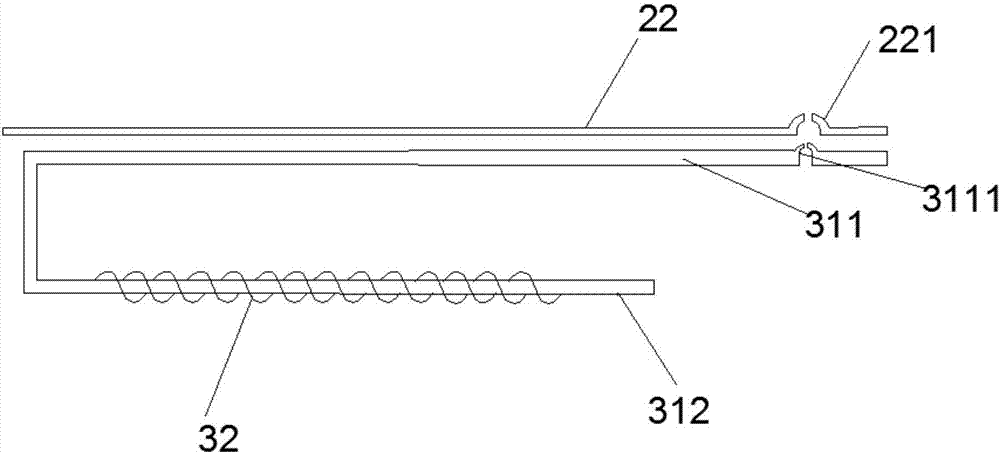

[0062] The acoustic membrane mechanism 2 divides the inner cavity into a first chamber 13 and a second chamber 14, wherein the acoustic membrane mechanism 2 can be arranged between the first housing 11 and the second housing 12, or be stuck in the first housing In body 11. The sound membrane mechanism 2 in this embodiment includes a fixed frame 21, a vibrating plate 22 and a sound membrane 23, the fixed frame 21 is connected to the housing 1, and the fixed frame 21 is fixedly instal...

Embodiment 2

[0084] Embodiment 2 provides a receiver, which is mainly different from Embodiment 1 in that the fixing unit is arranged in a different way, and the rest of the structure of the receiver in Embodiment 2 is the same as Embodiment 1.

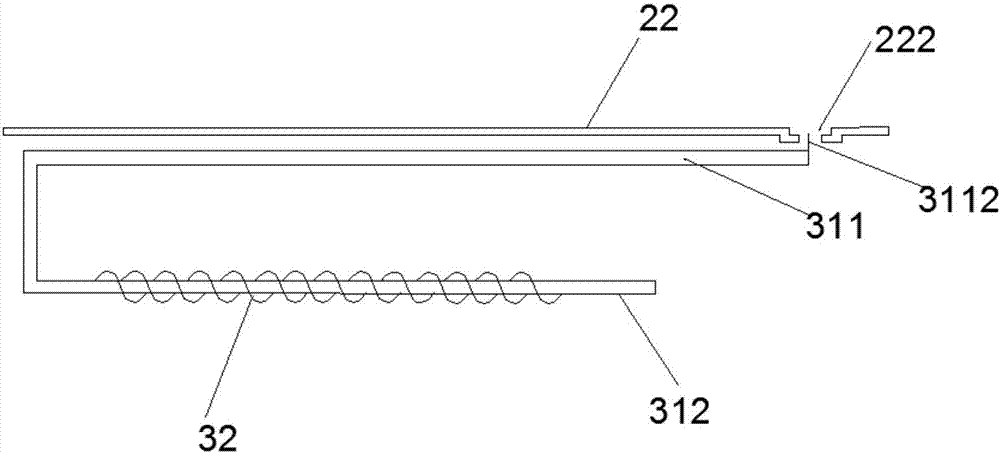

[0085] Such as figure 2 As shown, the fixing unit in this embodiment is a protrusion and a groove whose shape and size match. Wherein the end of the first arm unit 311 is provided with a sheet-like protrusion 3112, the opposite side of the vibrating plate 22 to the sound membrane 23 is provided with a groove that is sunken toward the armature, and the bottom of the groove is provided with a fixing hole 222. The shape protrusion 3112 is inserted into the fixing hole 222 . And the two are fixedly connected by injecting adhesive into the groove or welding and fixing the sheet-shaped protrusion in the groove, thereby ensuring the connection strength of the two and improving the connection reliability.

[0086] As an alternative embodiment, the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com