Metal sheet and method for its manufacture

A technology of plates and bottom plates, applied in the direction of manufacturing tools, sheets/plates, metal rolling, etc., can solve problems such as difficult maintenance work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

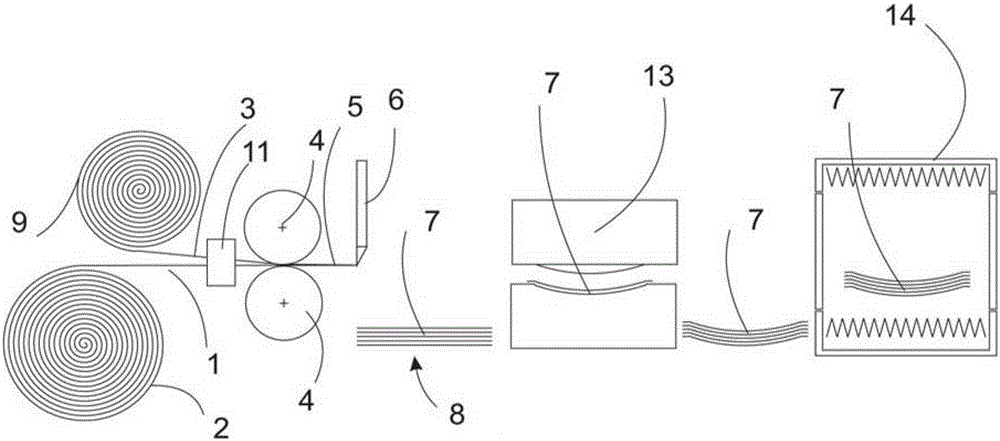

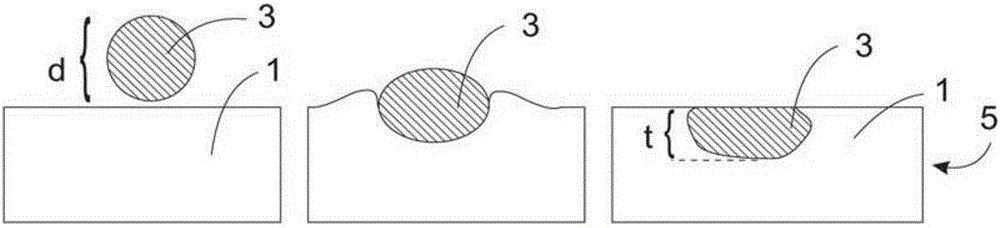

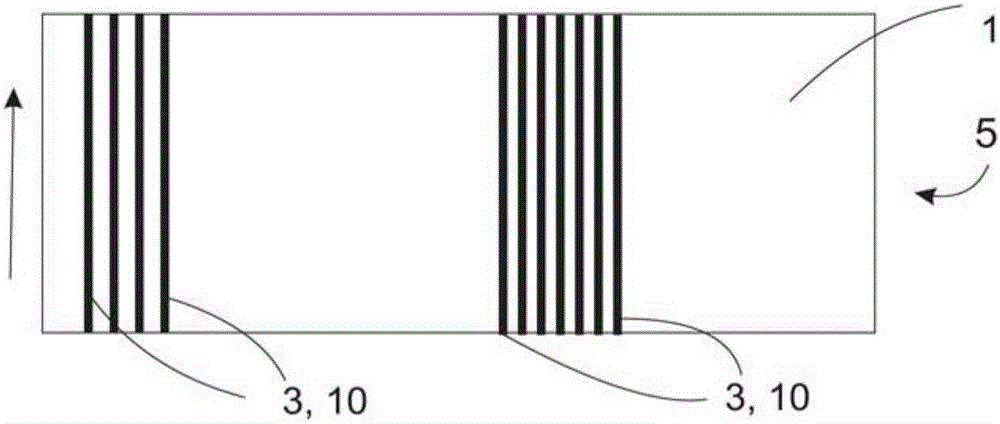

[0039] figure 1 The different stages of the method for producing a panel according to the invention are schematically shown. In the first stage, if figure 1 As shown on the left, a base plate 1 consisting of a low-alloy aluminum sheet, preferably an alloy of the alloy series 1xxx, is uncoiled from a coil 2 .

[0040] The reinforcement 3 in the form of a wire is drawn out of the coil 9 . The reinforcing element 3 can also consist of a plurality of wires which are uncoiled from adjacent coils 9 .

[0041] The reinforcement 3 here consists of a thermally curable aluminum alloy, preferably of the alloy series 6xxx. When in the initial state on the coil 9 , the reinforcement 3 has a greater strength than the base material 1 . The strength difference should be at least 200MPa.

[0042] The bottom plate 1 and the reinforcement 3 pass through the etching tank 11 . The etch bath can contain NaOH or HNO 3 . The oxide covering the surface of the base plate 1 and the reinforcement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com