Breaking hammer hydraulic oil pipe connecting mechanism

A technology of hydraulic oil pipes and connecting mechanisms, which is applied in the direction of adjustable connections, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of large stress load, easy to break, and affect the normal operation of the breaker, so as to reduce the force. Small, not prone to breakage, and has the effect of improving the rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

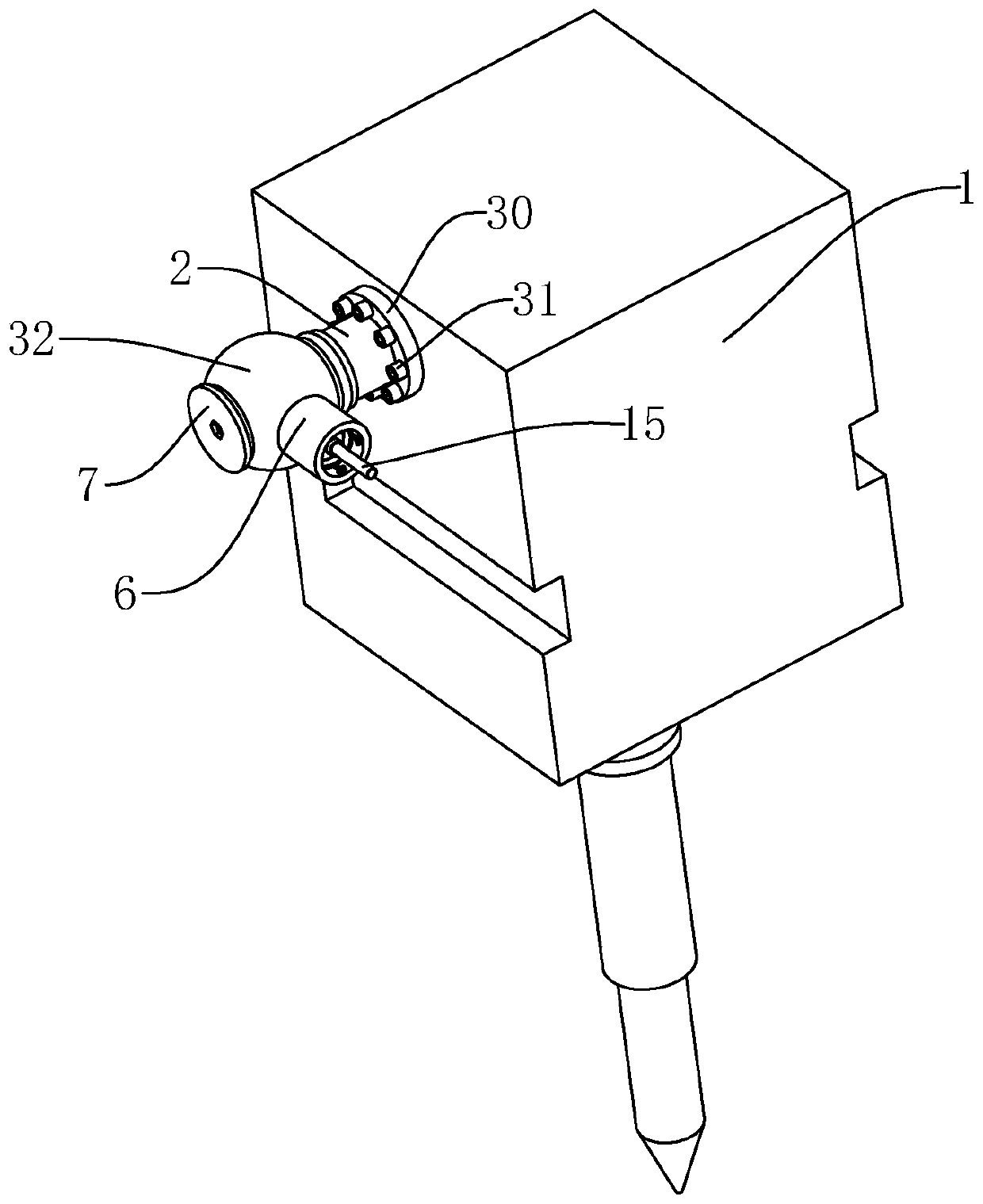

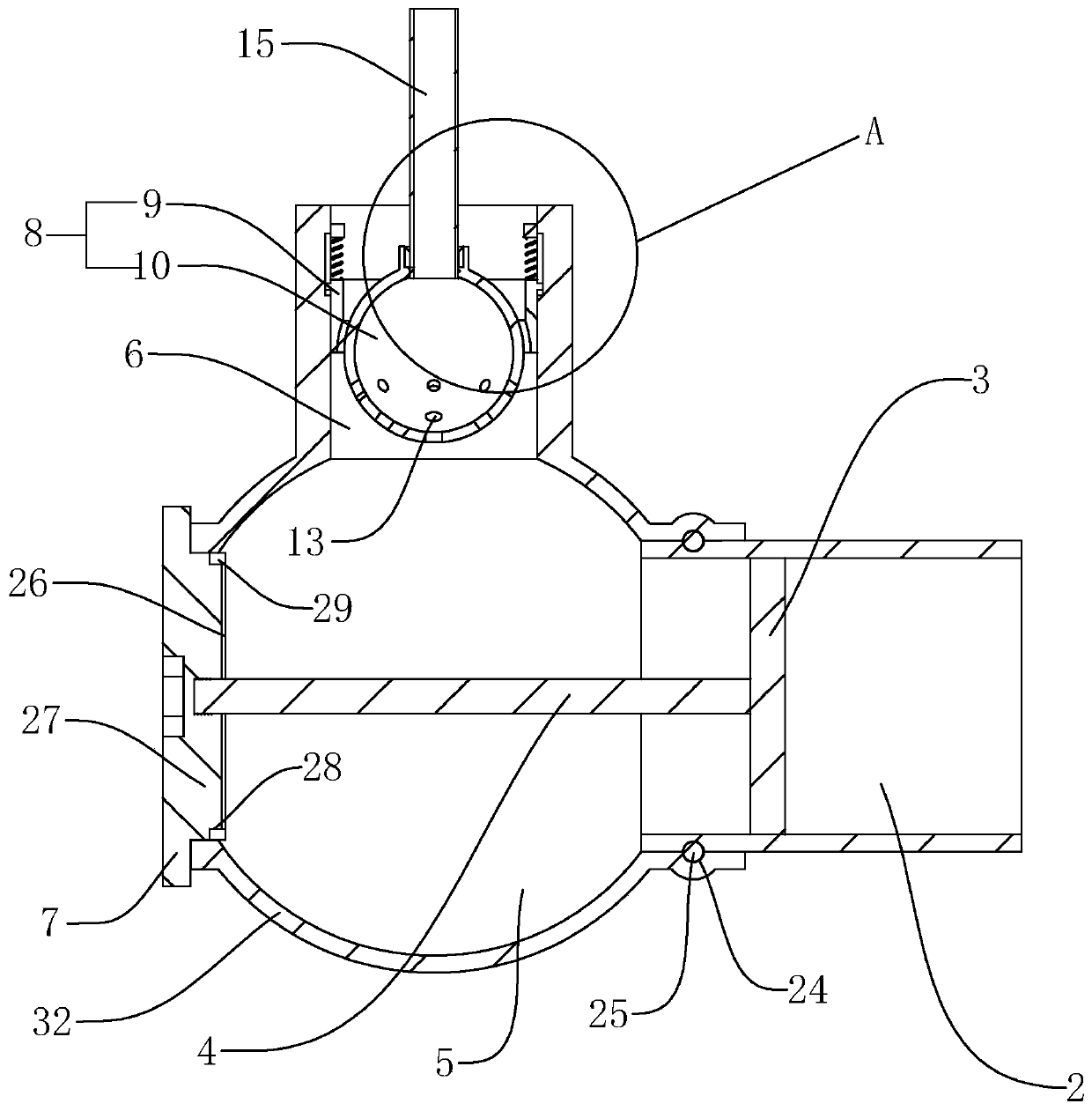

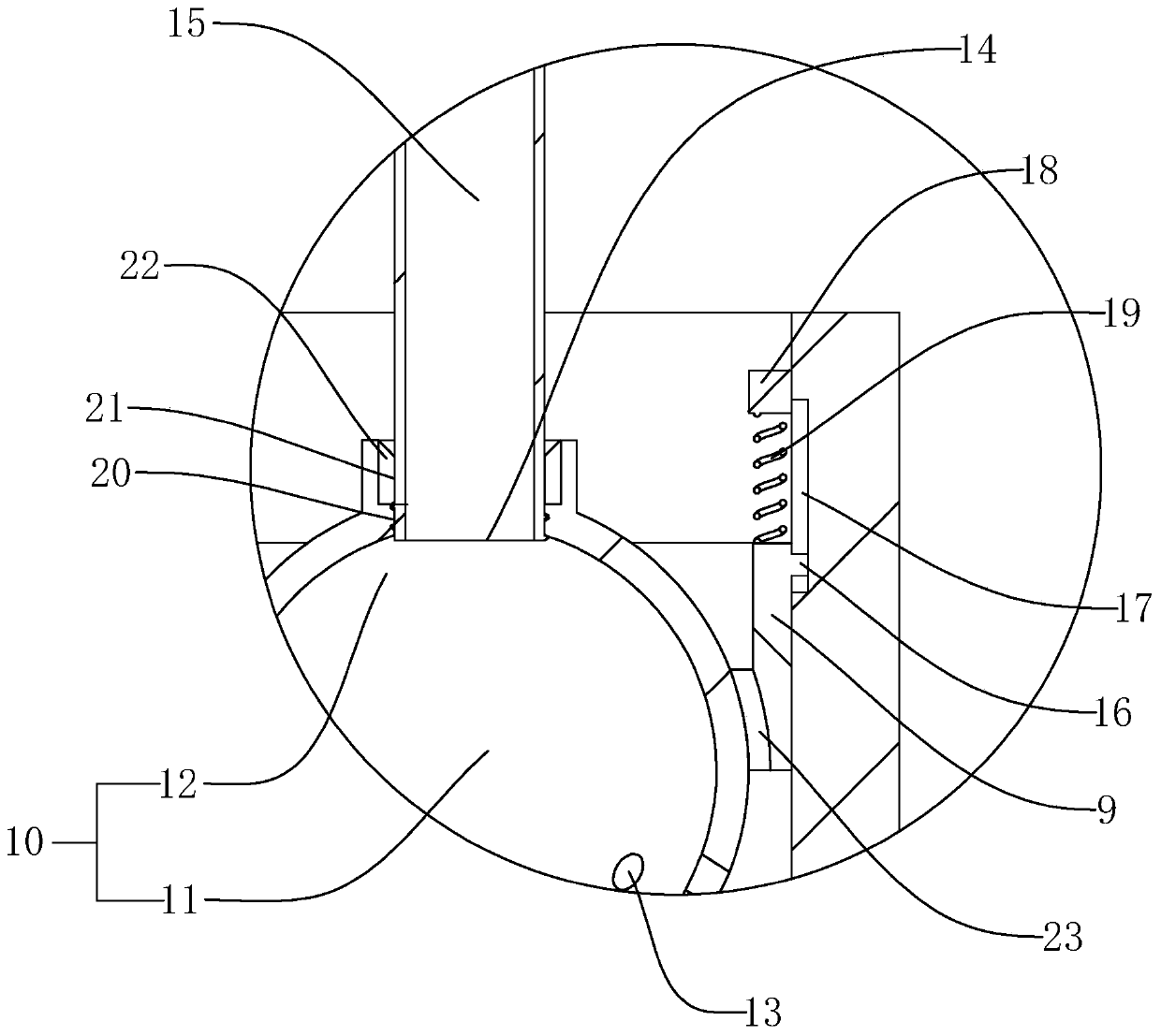

[0032] refer to figure 1 and figure 2 , is a hydraulic oil pipe connection mechanism for a breaking hammer disclosed in the present invention, including a hammer body 1, an oil injection channel 2 is fixed on the side wall of the hammer body 1, the oil injection channel 2 is located in the hammer body 1, and a vertical rod 3 is connected to the inner wall of the oil injection channel 2 , the middle part of the vertical rod 3 is fixedly connected with a fixed rod 4, and the fixed rod 4 protrudes from the oil injection channel 2 and is connected with a hollow ball head 32 for external rotation. 6 passes through the ball head 32 and extends into the oil chamber 5, the hydraulic oil flows from the oil inlet pipe 6 into the oil chamber 5, and then flows from the oil chamber 5 through the oil injection channel 2 into the hammer body 1. The outer wall of the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com