Pallet container

A technology for containers and pallets, which is applied in packaging and other directions, can solve the problems of weakening the rigidity of the tubular grid frame, reducing and weakening the rigidity of undeformed pipe rods, etc., and achieve the effect of increasing the bending rigidity, improving the rigidity, and reducing the swelling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

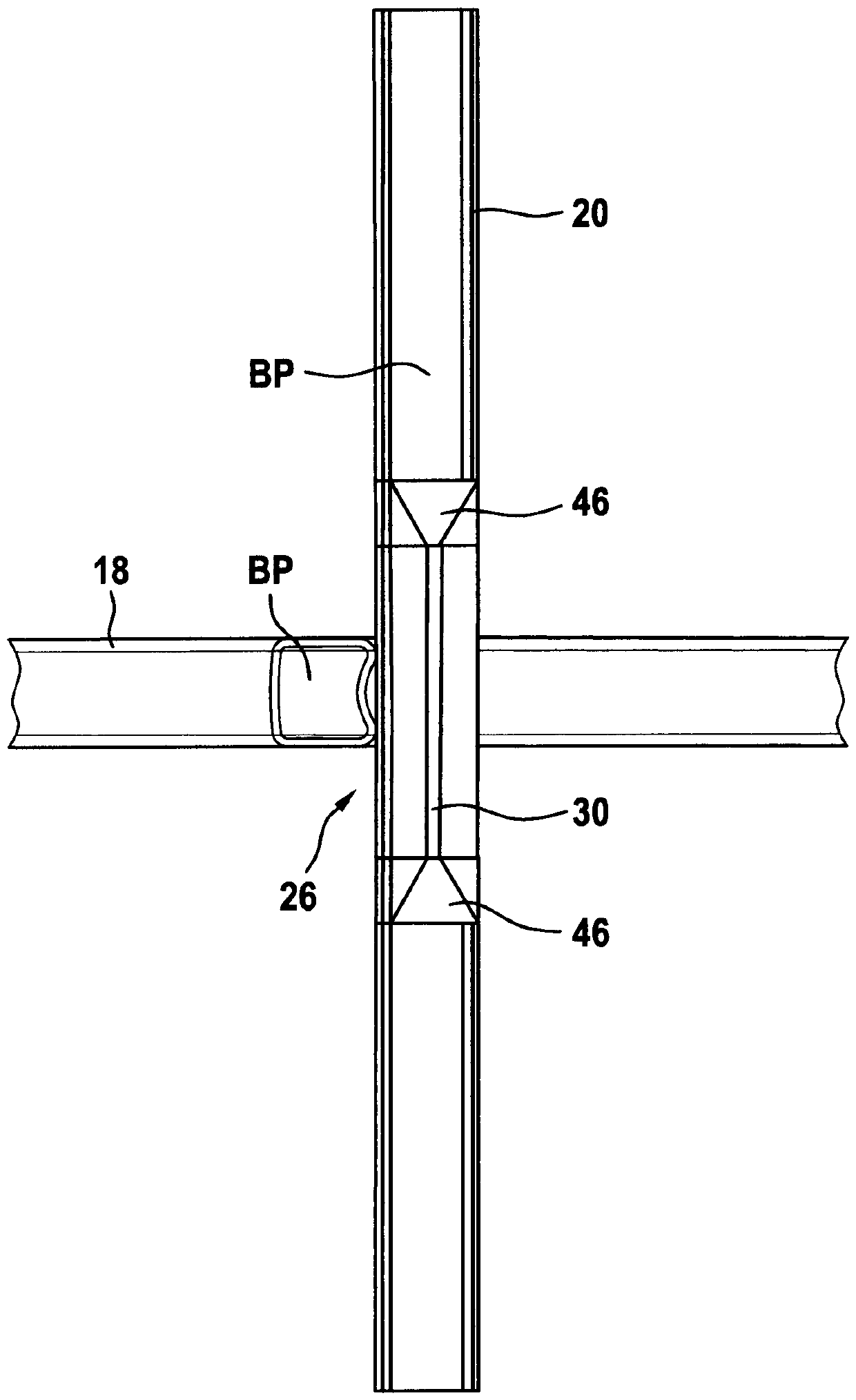

[0033] exist figure 1 A pallet container according to the invention for storing and transporting particularly hazardous liquid or flowable filling goods is designated with the reference numeral 10 . For storing and / or transporting dangerous goods, the pallet container 10 meets special inspection criteria and is provided with a corresponding official dangerous goods approval. In one embodiment for a stuffing volume of about 1000 1, the pallet container 10 has standardized dimensions with a length of about 1200 mm, a width of about 1000 mm and a height of about 1150 mm. The main elements of the pallet container 10 consist of a thin-walled rigid inner container 12 made of thermoplastic plastic in a blow-molding process, a steel pipe-type grid frame 14 tightly surrounding the plastic inner container 12 as a support cover, and a bottom pallet 16 , the plastic inner container 12 is placed on the bottom pallet and the steel pipe grid frame 14 is fixedly connected to the bottom palle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com