Multilayer glasses

A technology of double-layer glass and glass, which is applied in the direction of parallel glass structure, etc., can solve the problems of incongruity and influence of vision, and achieve the effect of excellent durability and excellent workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

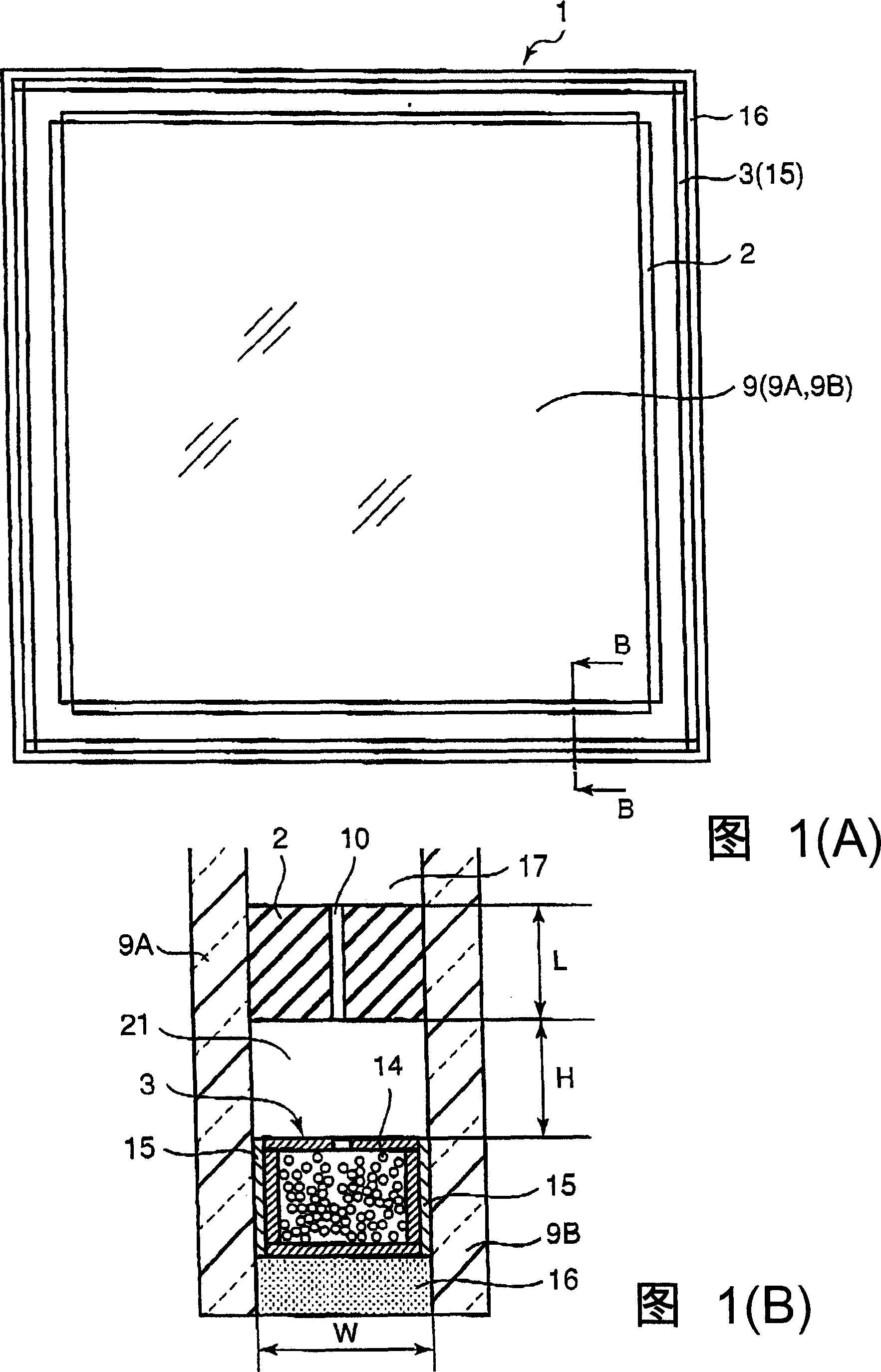

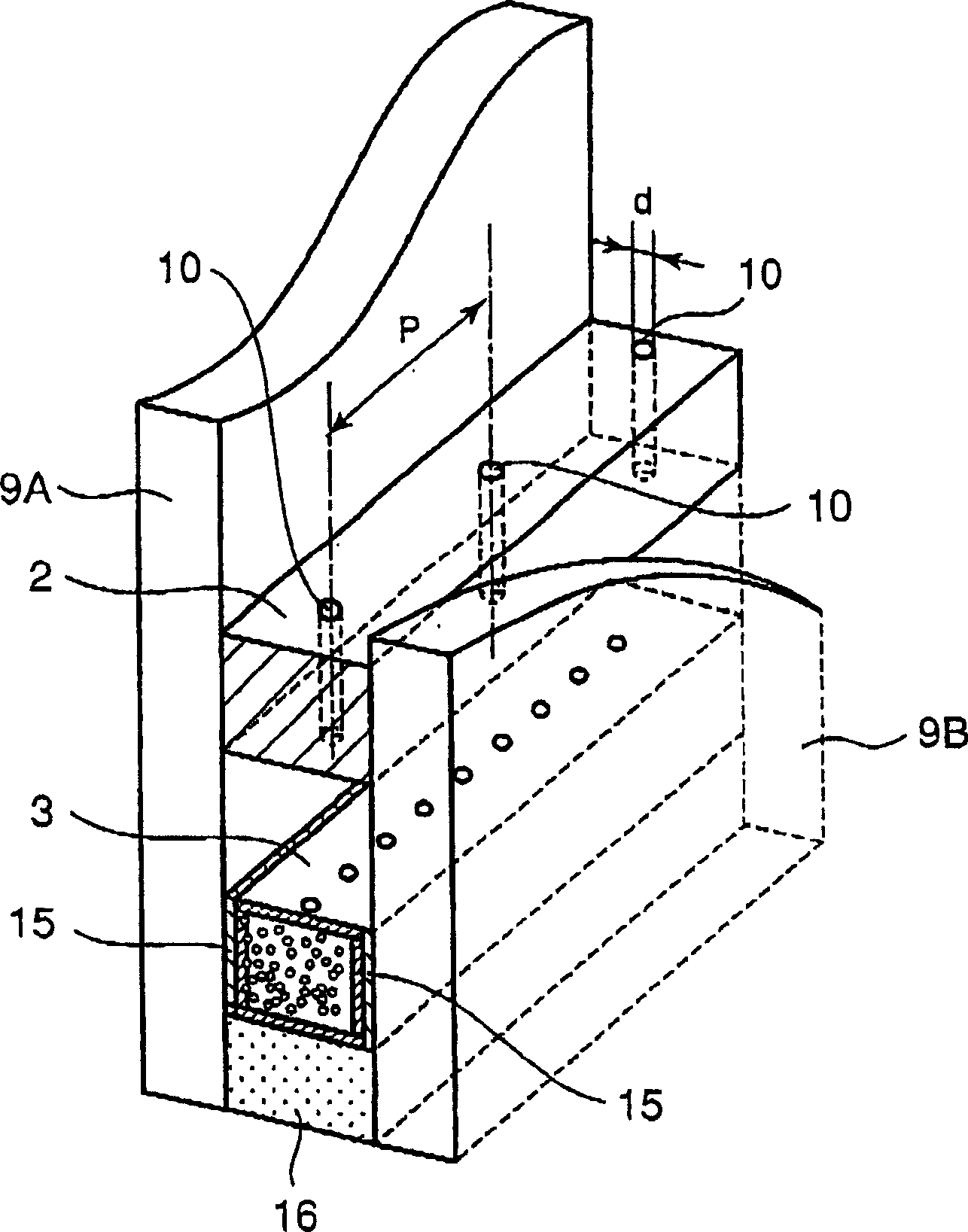

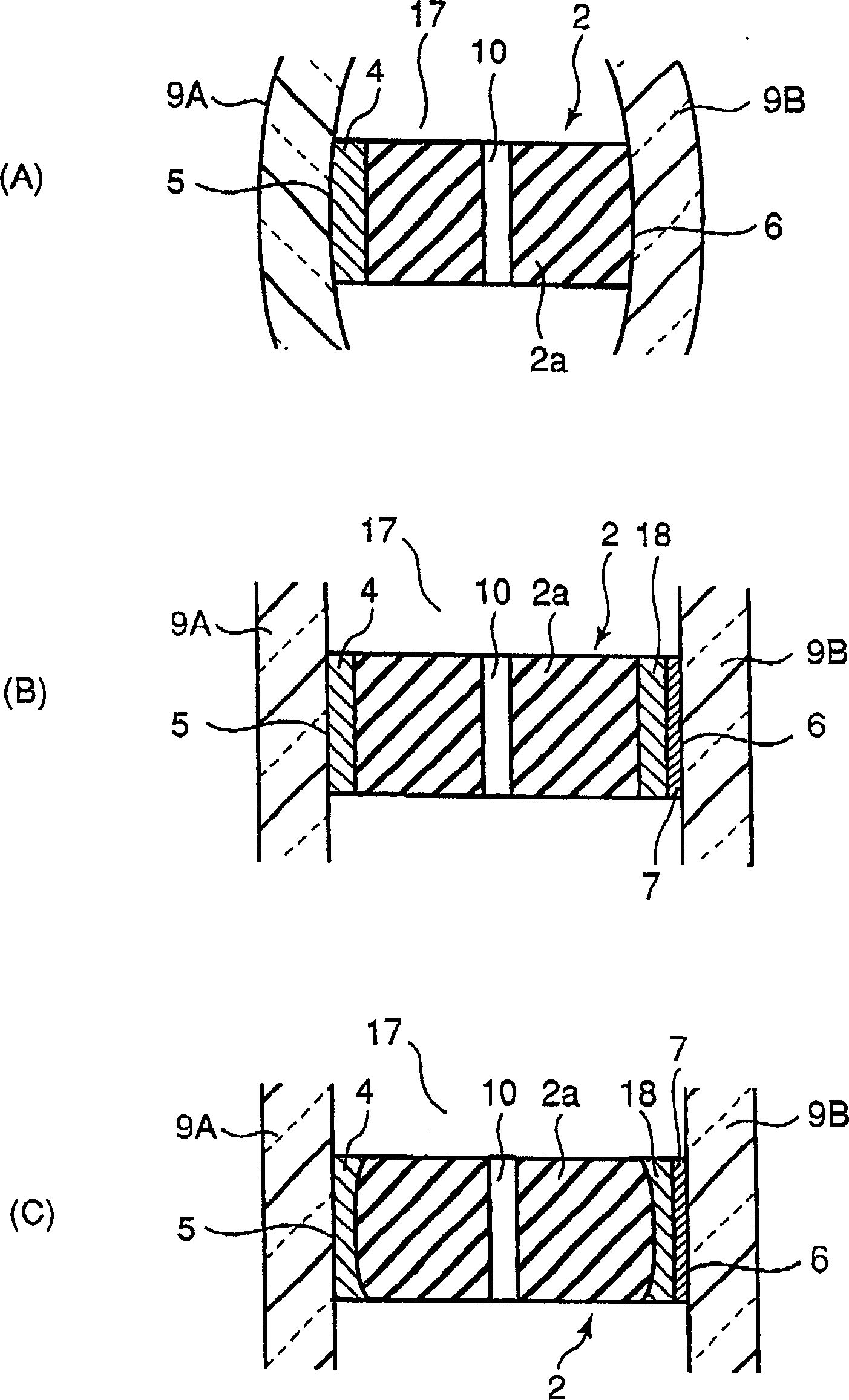

[0064] figure 2 (A) is a partial cross-sectional view around the resonance member of the double glazing according to the first embodiment of the present invention.

[0065] As shown in the drawing, the resonance member 2 having the small hole 10 is installed between the two plate glasses 9A and 9B. An inelastic fixing material 4 is provided between one side surface (left side in the figure) of the rigid body portion 2a of the resonance member 2 and the first plate glass 9A. That is, the opposing portion of the resonance member 2 that faces the first plate glass 9A is fixed to the first plate glass 9A on the adhesive surface 5 via the fixing material 4 . On the other hand, the opposing portion of the resonance member 2 corresponding to the second plate glass 9B is in airtight contact with the second plate glass 9B on the non-adhesive surface 6, and is non-contact with the second plate glass 9B. bonding. For the fixing material 4 , adhesives such as epoxy resin, silicone resi...

no. 2 Embodiment approach

[0079] Figure 4 (A) is a partial cross-sectional view around the resonance member of the double glazing according to the second embodiment of the present invention.

[0080] As shown in the figure, the double-layer glass according to the second embodiment of the present invention and figure 2 Compared with the double-layer glass according to the first embodiment of the present invention in (A), the only difference is that the part facing the first plate glass 9A in the resonance member 2 is placed on the bonding surface by the adhesive material 11 . 5 is adhered to the first plate glass 9A. which is, figure 2 In (A), the adhesive material 11 is used instead of the fixing material 4 between the first plate glass 9A and the resonance member 2 .

[0081] The adhesive material can be a pressure-sensitive adhesive, which can be bonded in a short time at room temperature with only a slight force. In addition, due to its cohesive force and elasticity, it can not only firmly bond ...

no. 3 Embodiment approach

[0089] Figure 5 (A) is a cross-sectional view around the resonance member of the double glazing according to the third embodiment of the present invention.

[0090] As shown in the figure, the resonance member 2 is bonded to the plate glass 9A, 9B on both sides of the rigid body portion 2 a with adhesive materials 11 , 11 . Therefore, even if the bonding position of the resonance member 2 with respect to the plate glass 9A, 9B is wrong, it can peel and stick again easily. The adhesive material 11 can be integrally molded simultaneously with the rigid body part 2a by extrusion molding of resin. Such integral molding eliminates the need to install the adhesive material 11 in the resonance member 2 in a separate process, thereby reducing work steps and improving production efficiency. The adhesive material 11 is preferably transparent in appearance like the resonance member 2 .

[0091] Figure 5 In (A), the adhesive materials 11, 11 are made of elastic soft resin, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com