In-situ measurement method and device for radial run-out of grinding wheel

A radial runout and measurement method technology, which is applied in the direction of measuring devices, workpiece feed movement control, instruments, etc., can solve the problems of not being able to measure the specific position of the high and low points of the runout, restricting the grinding process of the grinding wheel, and being unable to control the grinding wheel. Achieve the effects of reducing measurement difficulty, efficient on-site measurement, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

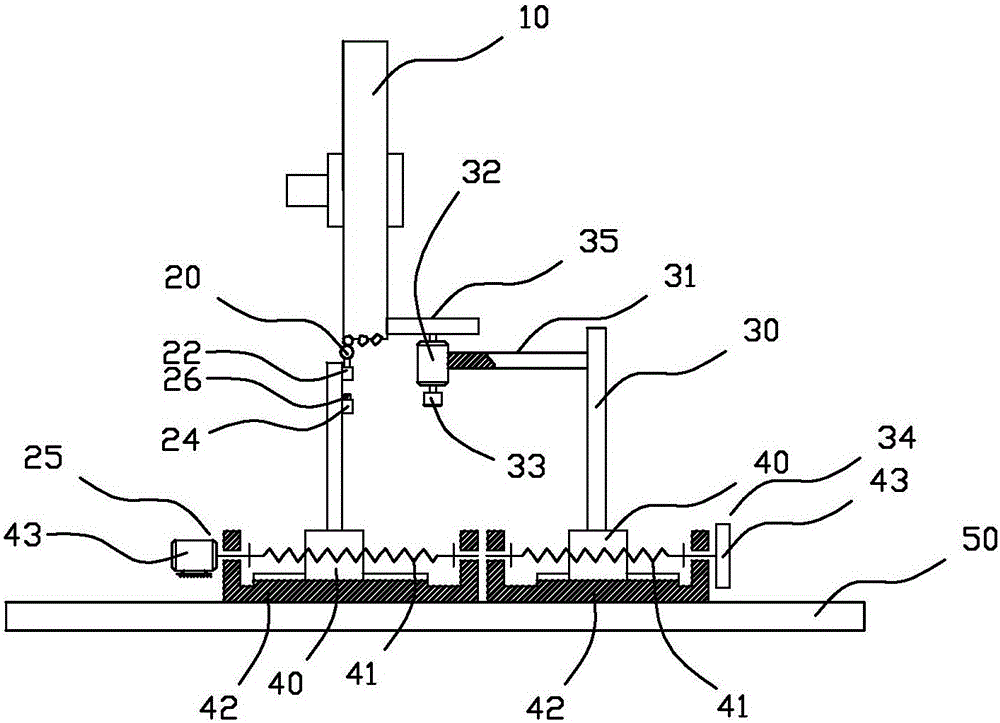

[0038] In order to solve the shortcomings of large measurement errors and incomplete measurement data in the prior art, the present invention provides an on-site measurement method for the radial runout of the grinding wheel, and an on-site measurement of the radial runout of the grinding wheel for realizing the method The device measures the radial runout of the grinding wheel and simultaneously measures the circumferential phase angle to obtain the specific position of the radial runout of the grinding wheel for effective control.

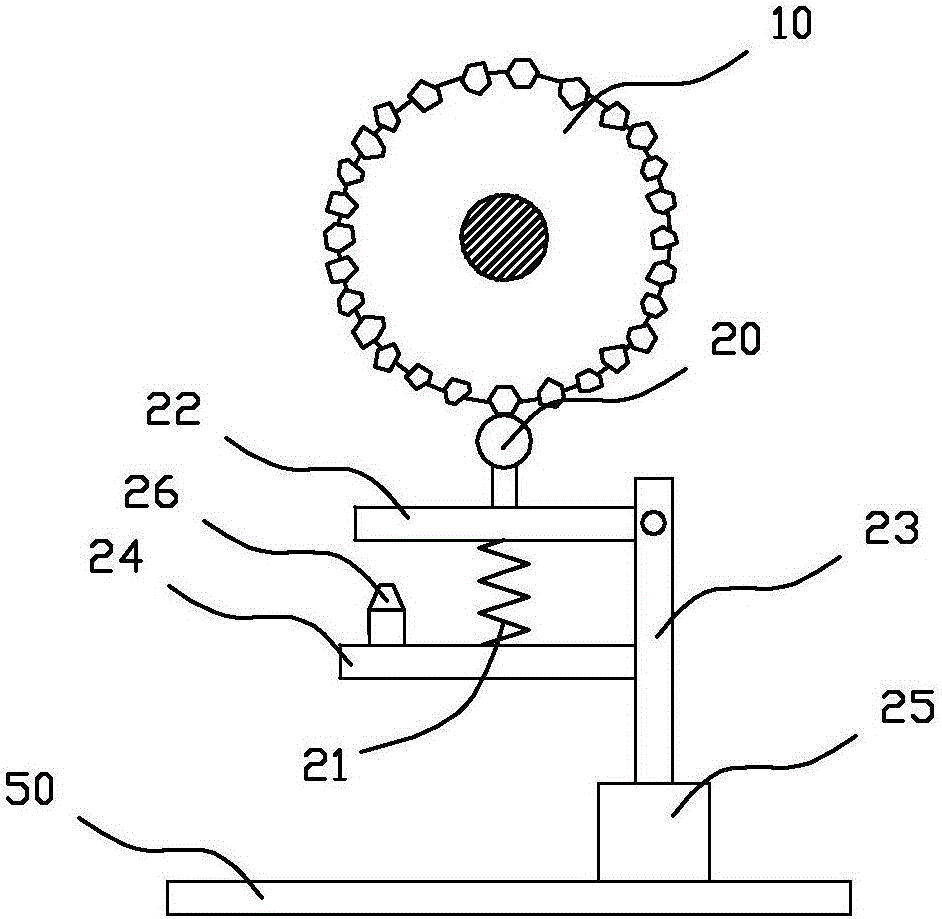

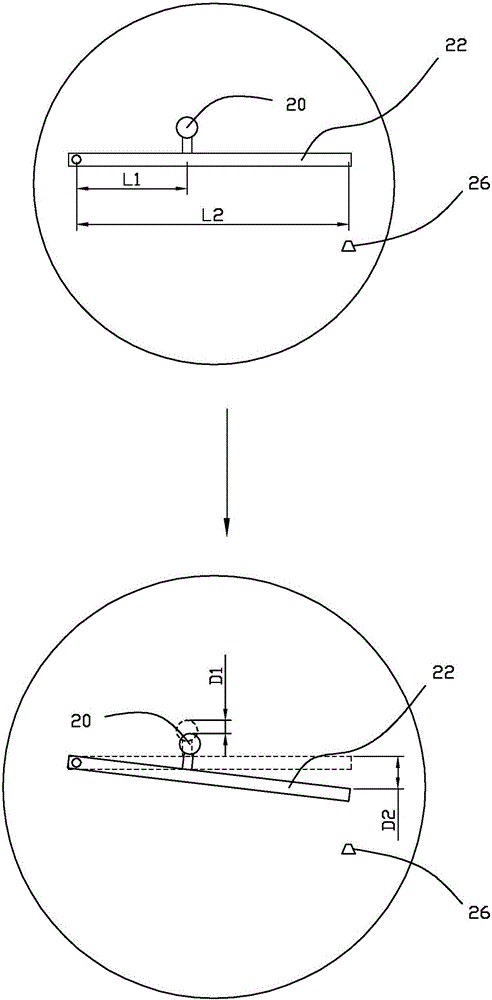

[0039]In the in-situ measurement method for the radial runout of the grinding wheel, the circumferential side of the grinding wheel 10 is inspected by the elastic contact, and the in-position grinding wheel 10 is driven by the driving mechanism to rotate to reflect the radial runout. The elastic contact keeps pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com