Pneumatic closure of ground yarn transportation into winding bobbin, and winding unit and automatic winder

An automatic winding machine and bottom yarn technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve the problem that the bottom yarn cannot be obtained by operators or maintenance units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

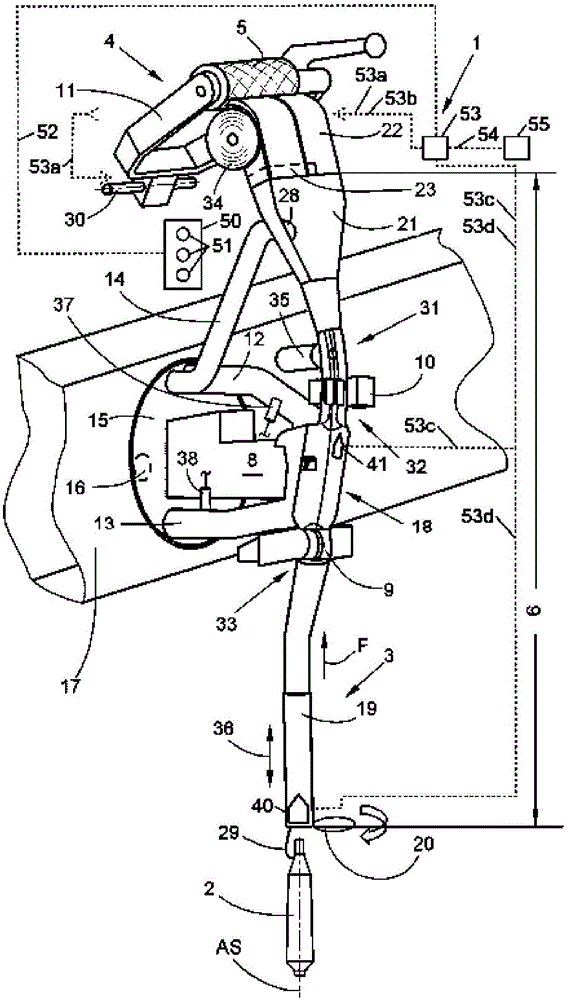

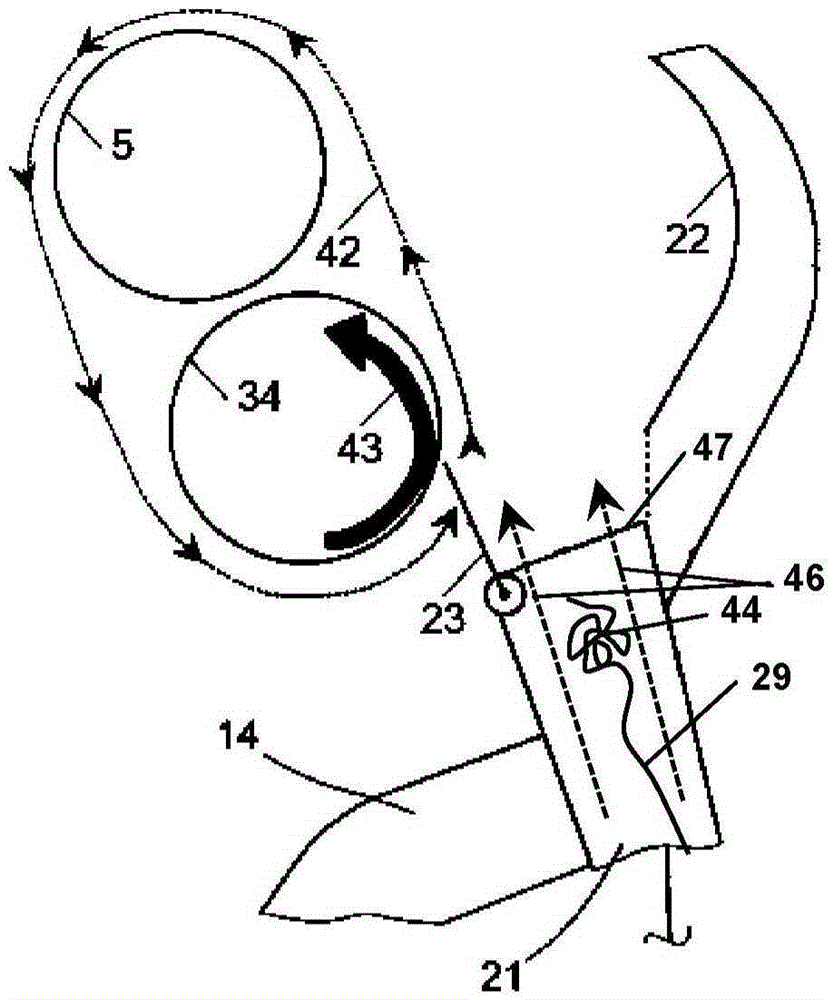

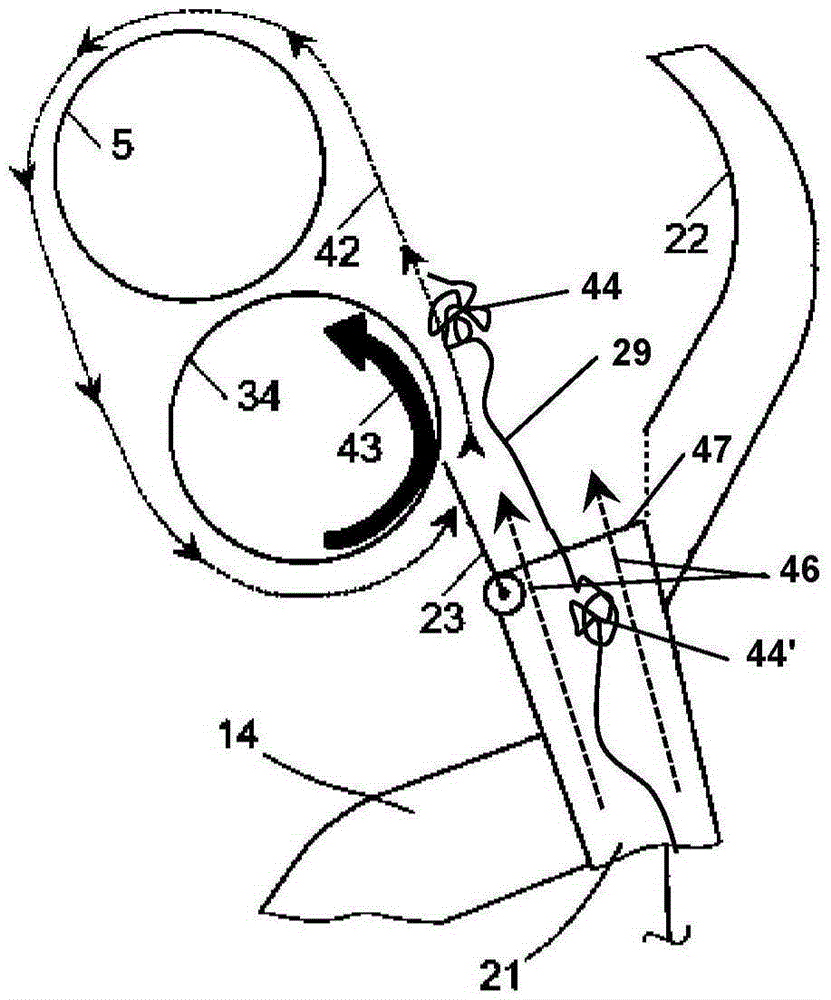

[0029] Basically taken from DE102010049515A1 (and numbered as such there) figure 1 A perspective view schematically shows a winding station 1 of an automatic winder with a multi-part yarn guide channel 6 surrounding the yarn path, which can be subjected to negative pressure and compressed air as required. The components and their mode of operation which are important for the understanding of the invention are described below, while further details on the mode of operation of the winding station 1 can also be found in DE 10 2010 049 515 A1.

[0030] The ground yarn 29 from the unwinding bobbin 2 in the unwinding position AS is guided in the yarn course F through the yarn guide channel 6 and rewound onto the winding bobbin 5 in the form of a cross-winding bobbin. The winding bobbin 5 is held in a creel 11 pivotable about a pivot axis 30 and is driven by a friction roller 34 which at the same time acts as a drum for the yarn traversal required to form a cross-wound bobbin. effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com