Mine hoist drum with skid resisting function

A mine hoist and functional technology, applied in the direction of the clockwork mechanism, the hoisting device, etc., can solve the problems of difficulty in processing spiral grooves, and achieve the effect of simple structure and avoiding rope bites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the invention is further introduced:

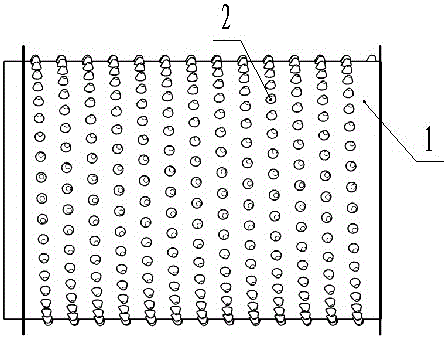

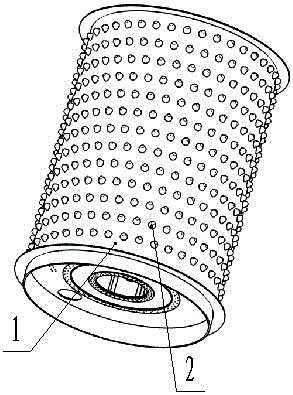

[0015] A mine hoist reel with anti-slip function, comprising a cylinder body 1, a plurality of bumps 2 are welded on the outer surface of the cylinder body 1, and the plurality of bumps 2 are spirally distributed on the outer surface of the cylinder body 1 .

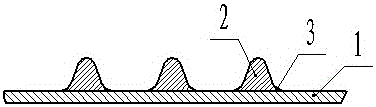

[0016] The upper part of the bump 2 is in the shape of a hemisphere, and the lower part is in the shape of a truncated cone.

[0017] A fillet 3 is provided at the welding place between the bump 2 and the cylinder body 1, and the radius of the fillet 3 is larger than the radius of the steel wire rope wound by the reel.

[0018] The above content is a further detailed description of the present invention in conjunction with specific preferred embodiments, and it cannot be assumed that the specific implementation of the present invention is limited to these descriptions. For those of ordinary skill in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com