Automatic deviation-preventing rope guider of winch

An anti-deviation, rope guide technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of poor winch reel, short life cycle and high cost of the wire rope, saving manpower and time, installation Convenience and simplicity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

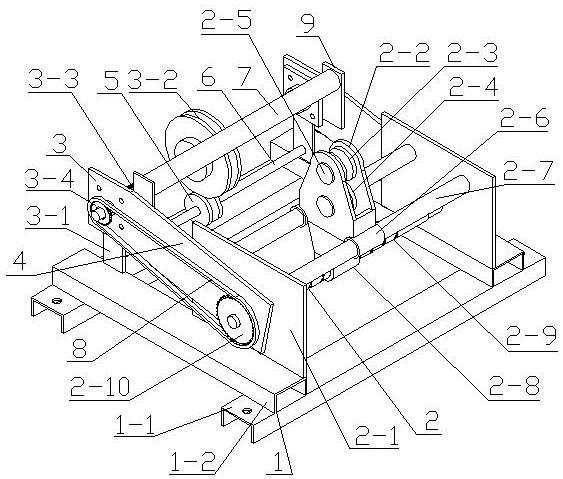

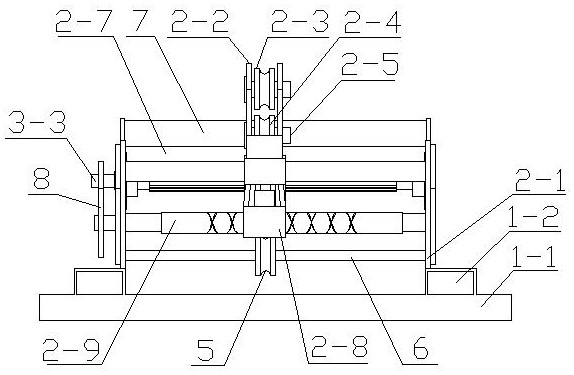

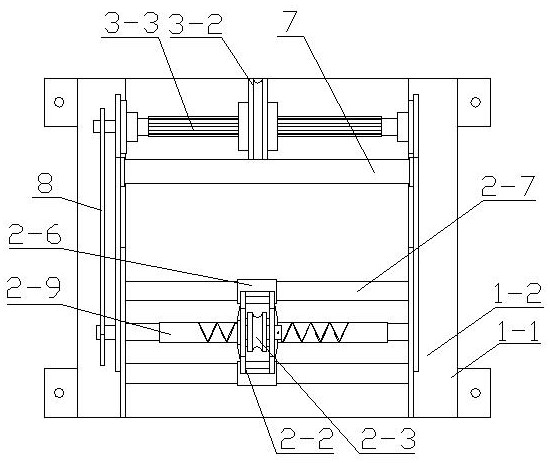

[0022] see Figure 1-Figure 5 , The present embodiment is an automatic anti-deviation rope guide for a winch, which is composed of a main frame 1, a reciprocating mechanism 2 and a wire rope friction drive mechanism 3 and the like. The main frame 1 is a rectangular channel steel welded member, which is composed of two transverse channel steels 1-1 and two longitudinal channel steels 1-2, and the two longitudinal channel steels 1-2 are placed on the upper part of the transverse channel steels 1-1 , The two ends of the transverse channel steel 1-1 are processed with mounting holes, which can be fixed with ground anchors.

[0023] The rear portion of the main frame 1 is provided with a reciprocating mechanism 2, and the reciprocating mechanism 2 is composed of a rear support 2-1, a reciprocating coil rope frame 2-2, an upper guide wheel 2-3, a lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com