A high-precision harmonic gear transmission built-in torque sensor and its measurement method

A technology of torque sensor and harmonic gear, which is applied in force/torque/power measuring instrument, measuring force, measuring device, etc., can solve the problems of increasing the number of parts of torque sensor, increasing the flexibility of transmission system, and complex system structure, etc. Achieve the effects of reducing weight and volume, less changes in mechanical parts, and reducing system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and implementation examples.

[0038] The invention obtains the magnitude of the moment by measuring the strain of the flexwheel of the harmonic gear transmission.

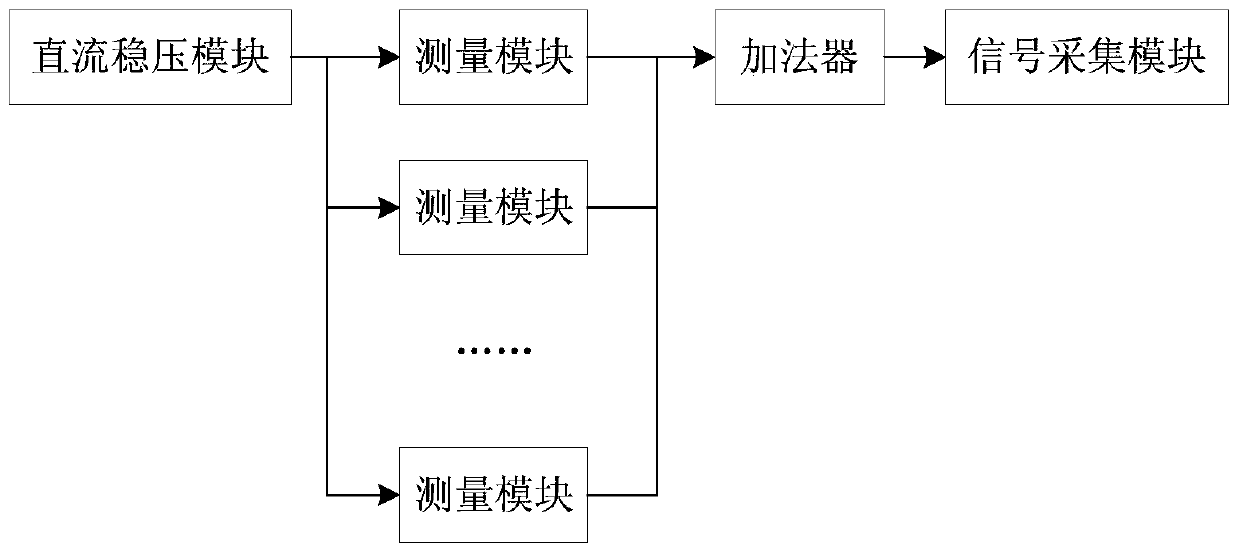

[0039] Such as figure 1 As shown, the device is composed of 1 DC voltage stabilization module, 10 measurement modules, 1 adder and 1 signal acquisition module. The DC voltage stabilization module provides power for other modules, and the output voltages of the 10 measurement modules are accumulated by an adder, and converted into digital signals by the signal acquisition module, which is the torque measurement value.

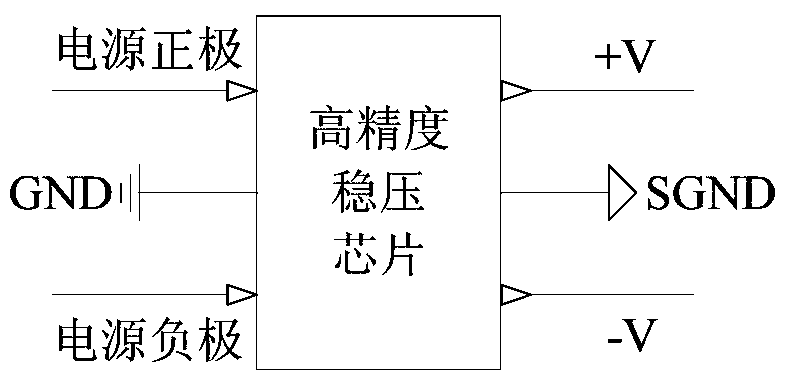

[0040] figure 2 It is a schematic diagram of a DC voltage regulator module, which uses a high-precision voltage regulator chip to convert the power supply voltage into high-precision and low-noise positive and negative voltages (±V) and digital ground (SGND).

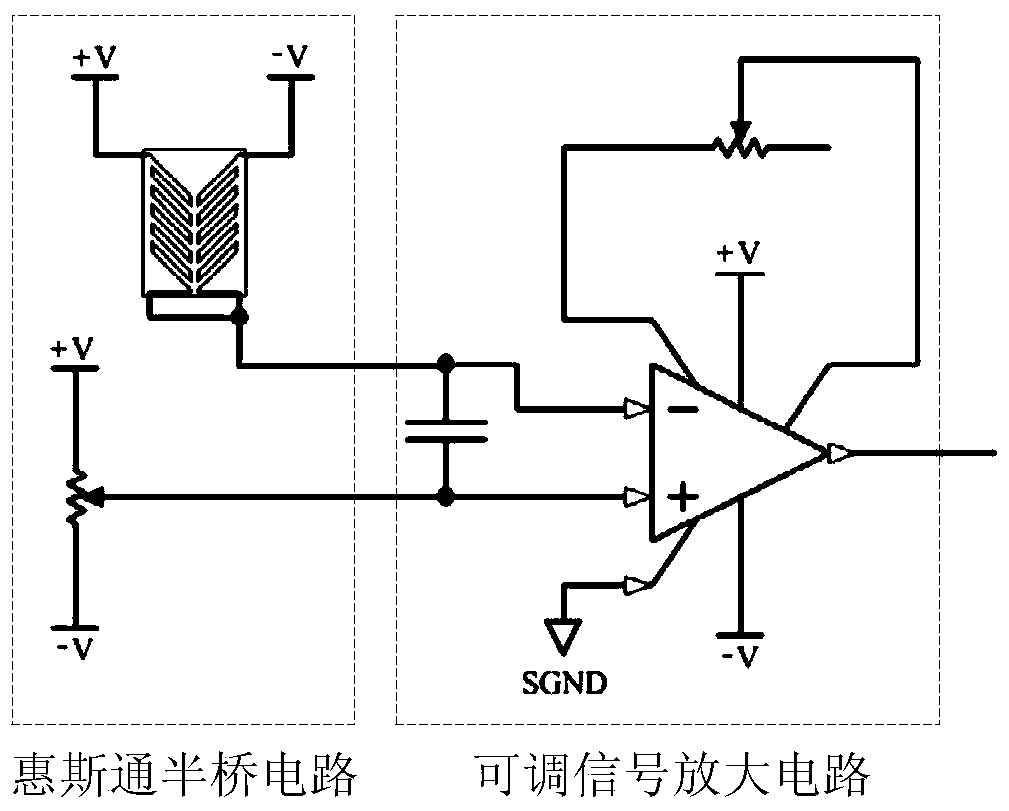

[0041] image 3 It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com