Amorphous reactor

A reactor and amorphous technology, applied in the field of amorphous reactors, can solve the problems of reducing the volume of reactors, occupying a large space, and inconvenient installation, so as to reduce the overall space ratio, facilitate maintenance and replacement, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

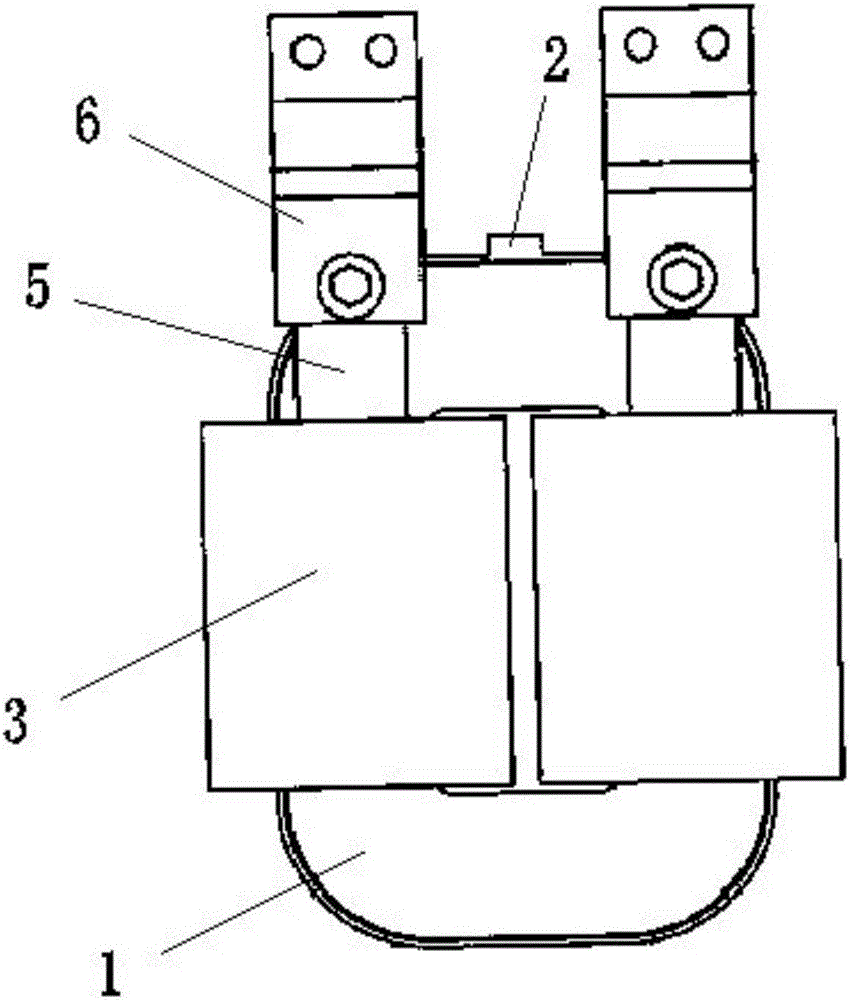

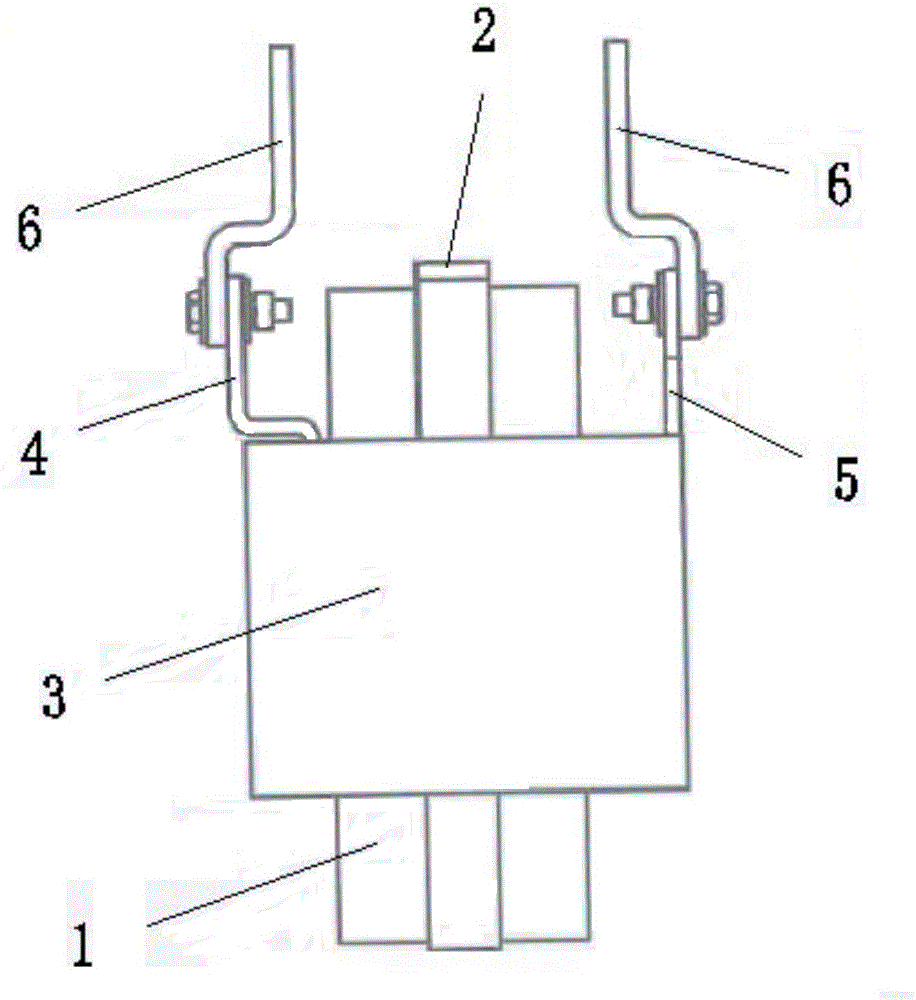

[0013] The present invention is described below in conjunction with accompanying drawing.

[0014] as attached Figure 1-2 As shown, an amorphous reactor according to the present invention includes a casing. For the convenience of illustration, the casing is not shown in the figure. An amorphous iron core 1 is arranged in the casing, and the amorphous iron core 1 passes through the hoop 2 fastening, two groups of coils 3 are arranged on the amorphous iron core 1, and the two groups of coils 3 are respectively arranged on both sides of the amorphous iron core 1; each group of above-mentioned coils 3 is provided with a first contact 4 and The second contact 5, the first contact 4 and the second contact 5 are drawn from the upper side of the coil 3; the first contact 4 includes a vertical part and a bent part, and the bent part is drawn from the coil 3 , the vertical part is arranged on the bending part, the distance from the vertical part to the center line of the amorphous iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com