Simple hoisting mechanism

A simple hoisting technology, applied in cranes, transportation and packaging, etc., can solve the problems of complicated installation, disassembly, maintenance procedures, complex hoisting mechanism structure, single hoisting function, etc., saving manpower and material resources, scientific and reasonable design, simple hoisting Institutional Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

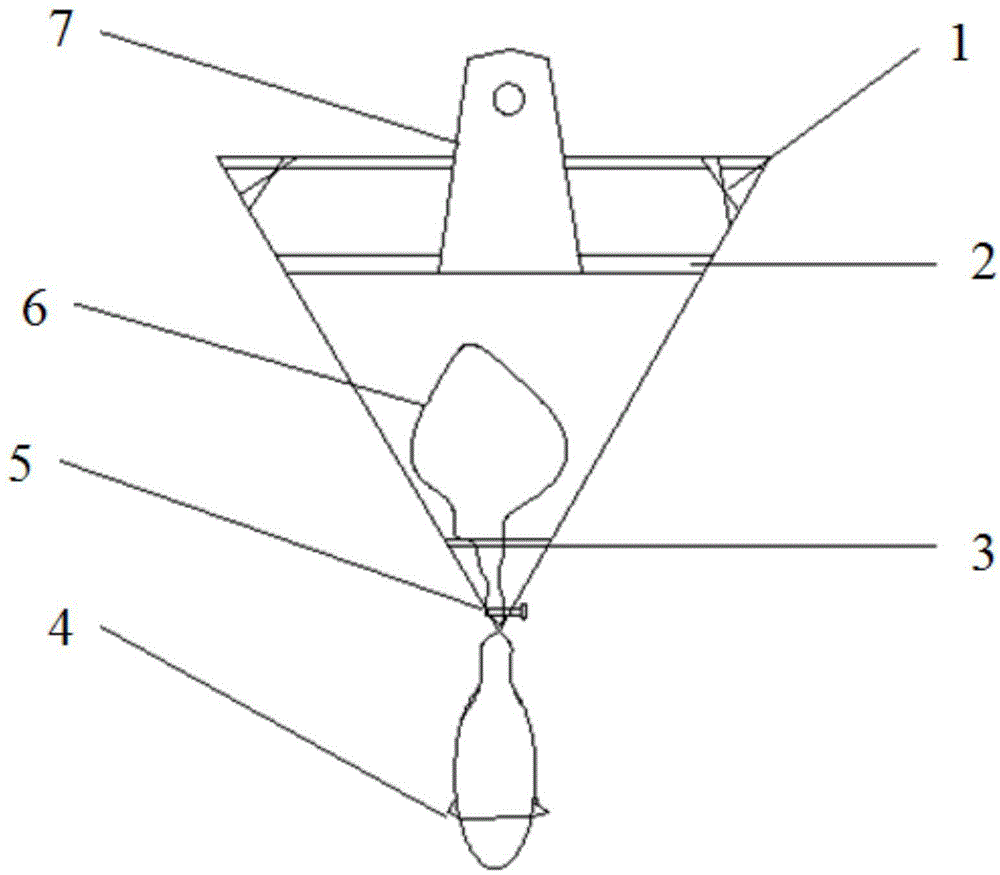

[0012] A simple hoisting mechanism, including a frame, a hoisting mechanism and a fixing mechanism, the frame is an inverted triangle structure, including a frame body, a reinforcing rib 1, and a support plate 2, and the hoisting mechanism includes a hoisting plate 7 and hoisting cables 6. The fixing mechanism includes an arresting rod 3, a shut-off valve 5 and a rope lock 4. The hoisting mechanism is placed inside the frame. The board is placed under the reinforcing rib and fixedly connected to both sides of the frame. The bottom of the hoisting board is connected to the support board according to regulations, and the top is provided with hoisting holes. The arresting board is provided with 2 holes, and the arresting board is placed under the supporting board. It is fixedly connected with both sides of the frame, the cut-off valve is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com