Camera module motor, camera module and electronic device

A camera module and motor technology, applied in TV, electrical components, color TV, etc., can solve the problems of magnet 3 multi-space, camera module motor volume, camera module volume, etc., to achieve the effect of reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] As mentioned in the background art, the camera module motor in the prior art needs a magnet to provide a magnetic field, which leads to a large volume of the camera module motor, and thus makes the camera module using the camera module motor Larger volume.

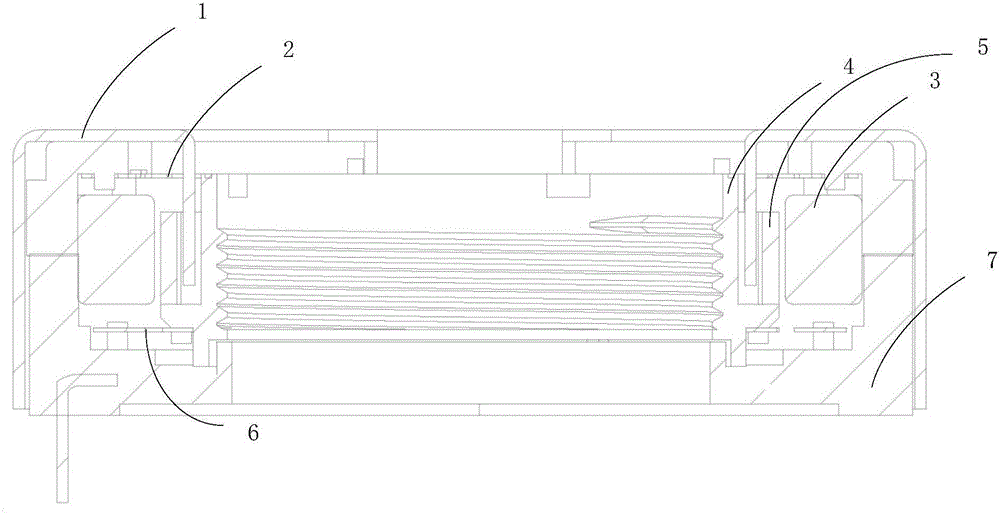

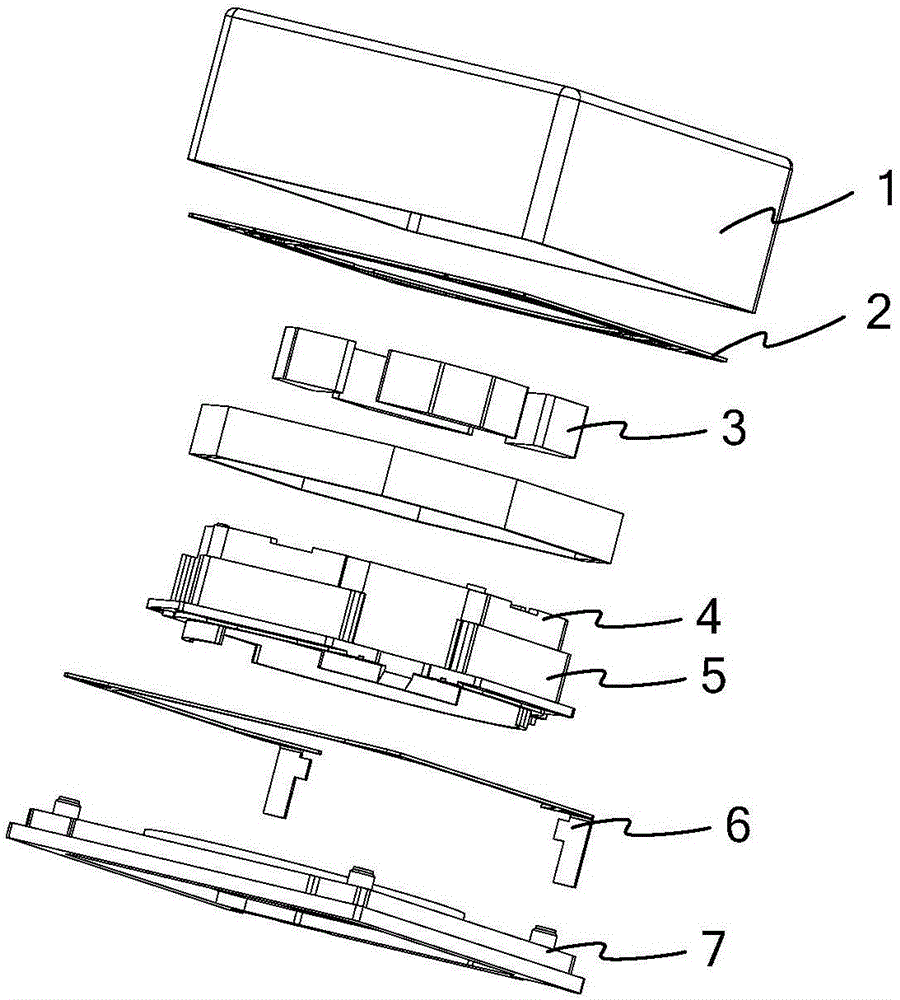

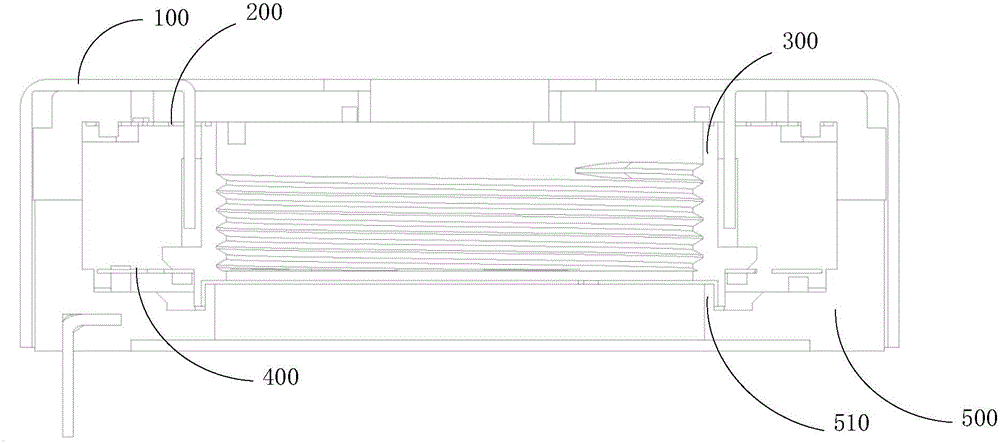

[0025] In view of this, the embodiment of the present application provides a camera module motor, which includes a housing, an upper elastic piece, a lens carrier, a coil, a lower elastic piece and a base, and the housing and the base form a hollow receiving cavity after fitting , the upper elastic piece, the lens carrier and the lower elastic piece are located in the storage cavity, and the lens carrier accommodates a lens;

[0026] The coil is wound on the surface of the lens housing and is located between the lens housing and the dustproof wall of the housing;

[0027] The dustproof retaining wall of the housing is magnetic.

[0028] Correspondingly, the embodiment of the present application also provides a cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com