A heating component in an ICP etching device and a method for arranging the heating component

A technology for heating components and devices, applied in induction heating devices, induction heating and other directions, can solve problems such as cracking, achieve the effect of improving capacity and uniformity, and reducing the influence of induction magnetic fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

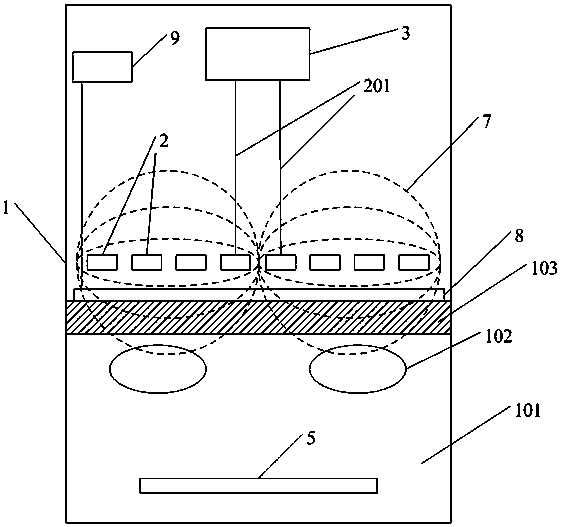

[0041] based on the following Figure 3 ~ Figure 5 , specifically explain the preferred embodiment of the present invention.

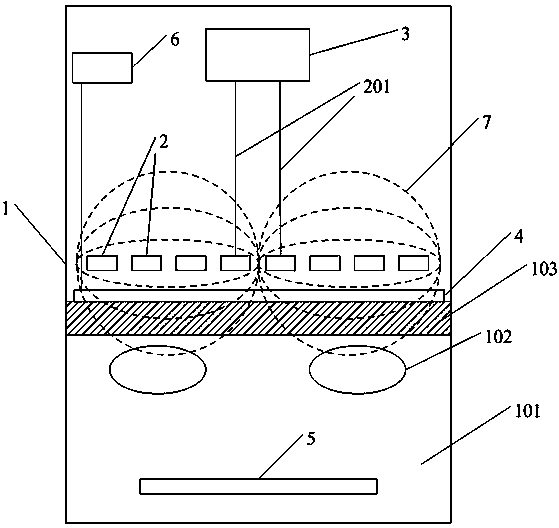

[0042] Such as image 3 Shown, described ICP etching device 1 comprises:

[0043] An induction coil 2, the two ends of the induction coil 2 are connected to the radio frequency source 3 through a lead wire 201, and under the excitation of the radio frequency source 3, the induction coil 2 generates an induced magnetic field;

[0044] A vacuum chamber 101, the reaction gas in the vacuum chamber 101 generates a plasma 102 under the action of the induced magnetic field generated by the induction coil 2, and etches the semiconductor substrate 5;

[0045] A ceramic radio frequency window 103, which isolates the induction coil 2 from the vacuum cavity 101, the ceramic radio frequency window 103 is flat or dome-shaped;

[0046] The heating assembly 8 includes a resistance wire 801 and a power source 9 connected to both ends of the resistance wire. The resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com