Front disc and rear disc combined hand brake system

A handbrake, front pump technology, applied in bicycle accessories, bicycle brakes and other directions, can solve the problems of poor braking effect, unsafe operation, laborious and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

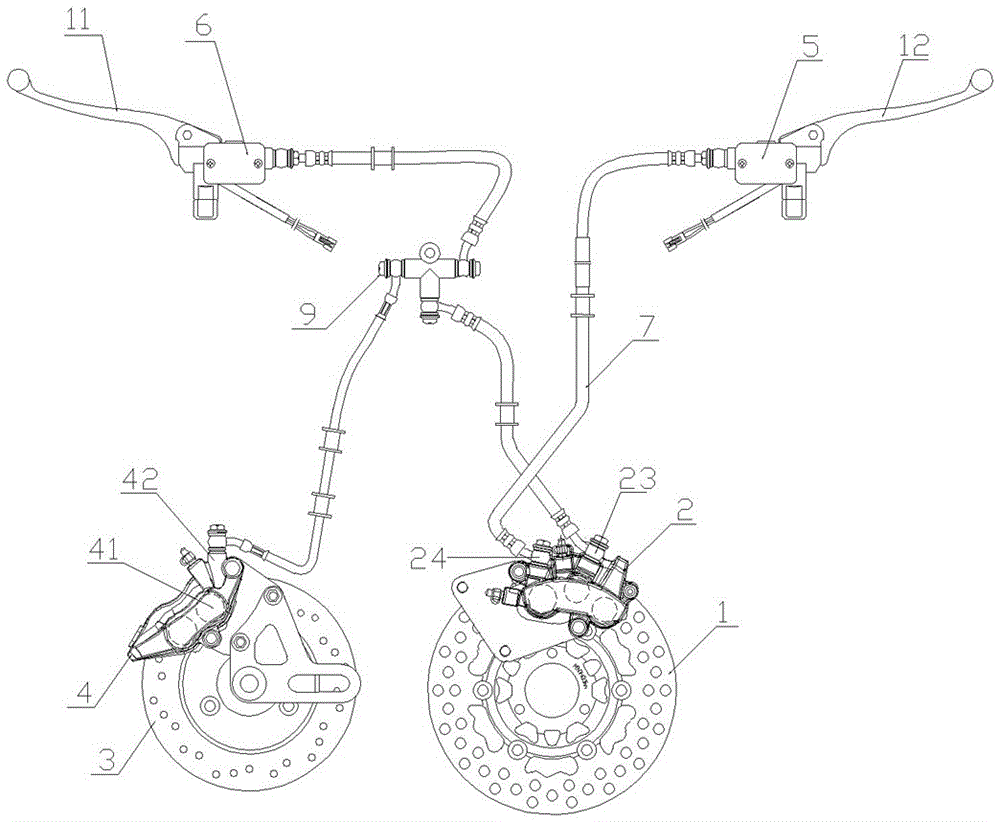

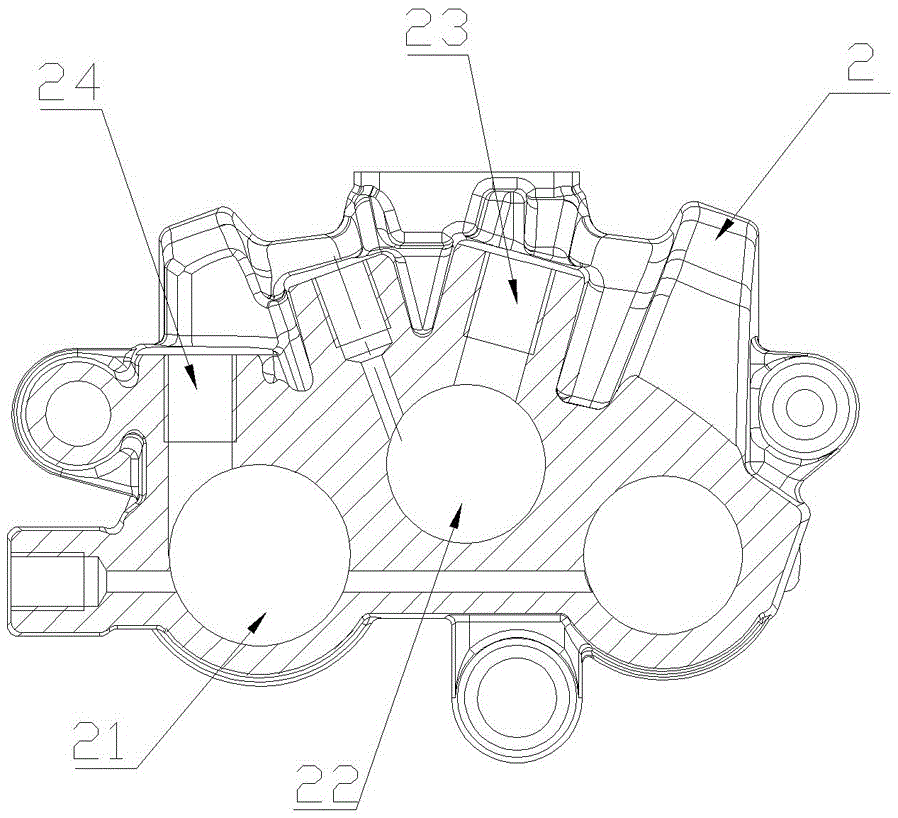

[0011] Refer to attached figure 1 , a front-disc and rear-disc combined handbrake system, including a front brake cylinder 2 fixed on a front wheel 1, a rear brake cylinder 4 fixed on a rear wheel 3, a front pump 5, a rear pump 6 and several oil pipes 7 , the front pump 5 and the rear pump 6 are respectively fixed on the left and right handles of motorcycles or electric vehicles, and the brakes are controlled by hand, and the front brake cylinder 2 and the rear brake cylinder 4 are pushed by the oil cylinder to implement hydraulic braking.

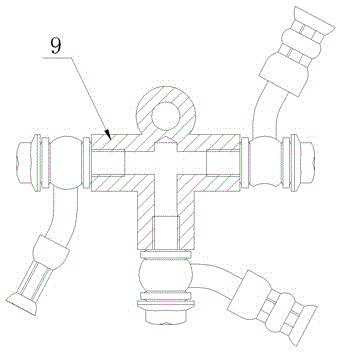

[0012] Refer to attached figure 1 And attached figure 2 , the hand brake system also includes a three-way connector 9 that divides the rear brake oil circuit into two. The three-way connector 9 is a "T"-shaped three-way pipe with three ends. The front brake cylinder 2 There are more than two oil cylinders and two oil inlets, one of which is connected to the front pump 5 through the oil pipe 7, and the other oil inlet is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com