A stacking rgv vehicle

A stacking and frame technology, applied in the direction of conveyors, storage devices, mechanical conveyors, etc., can solve the problem of inaccurate lifting height of RGV vehicles, achieve the effect of reducing space and ensuring balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

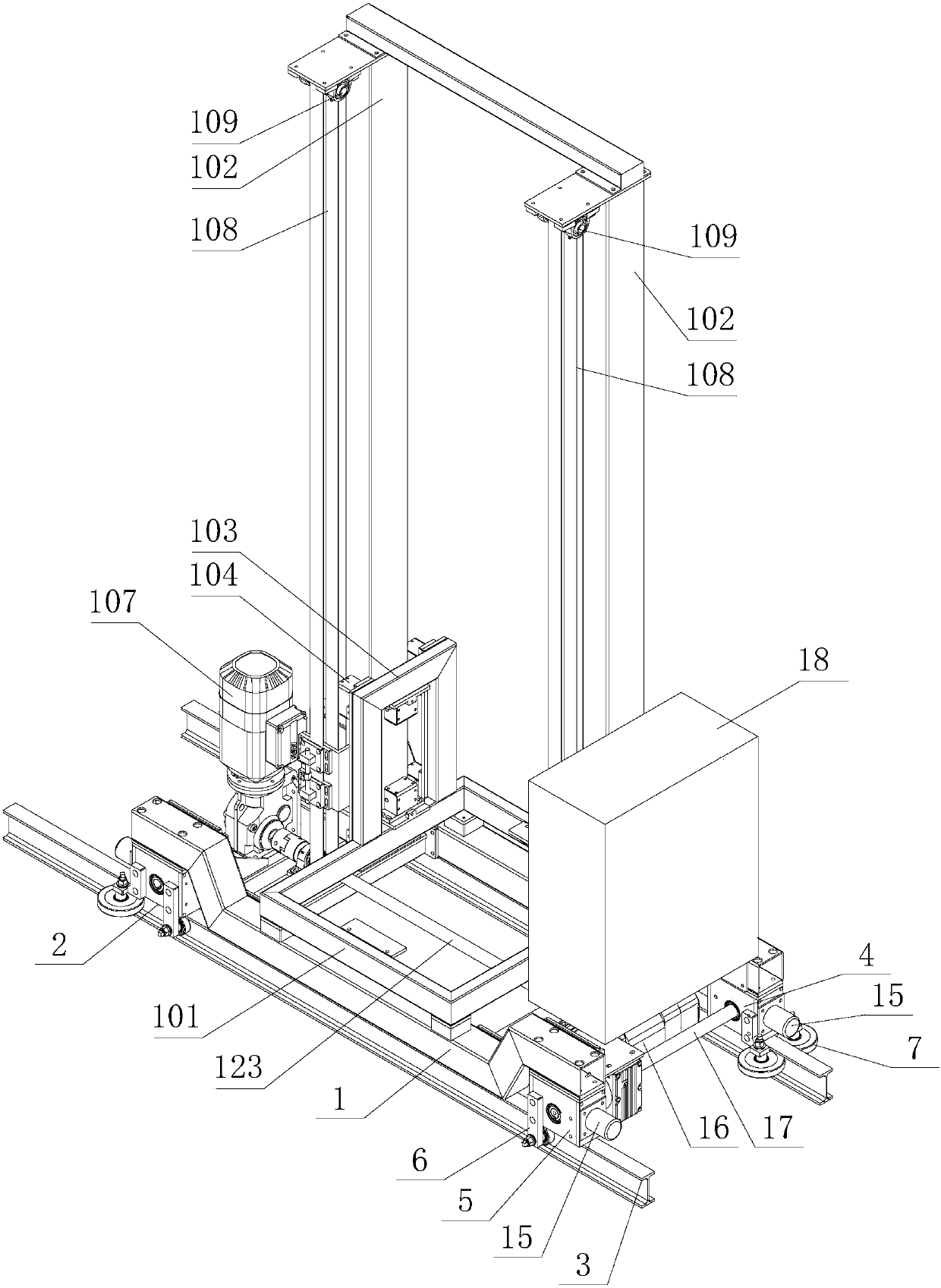

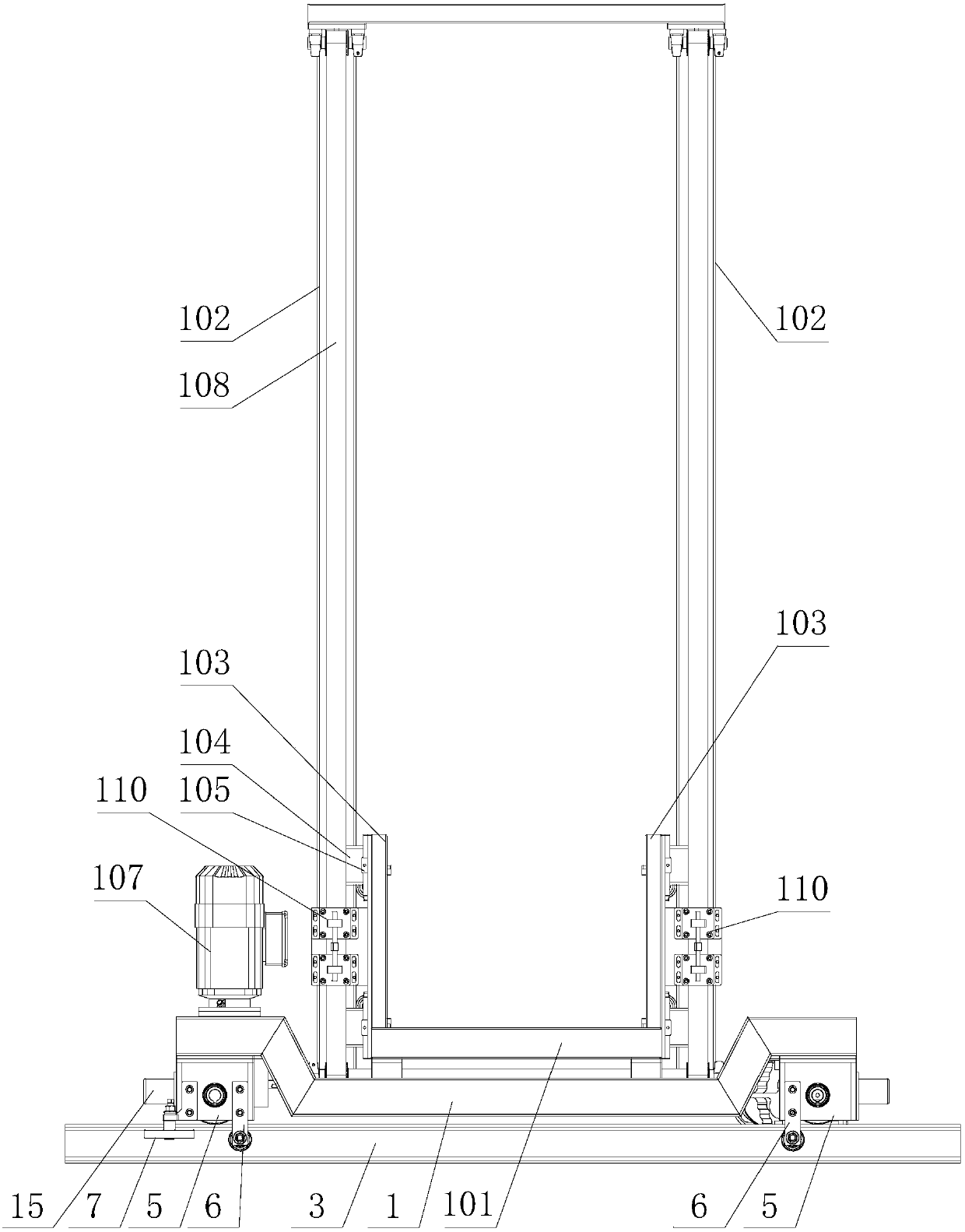

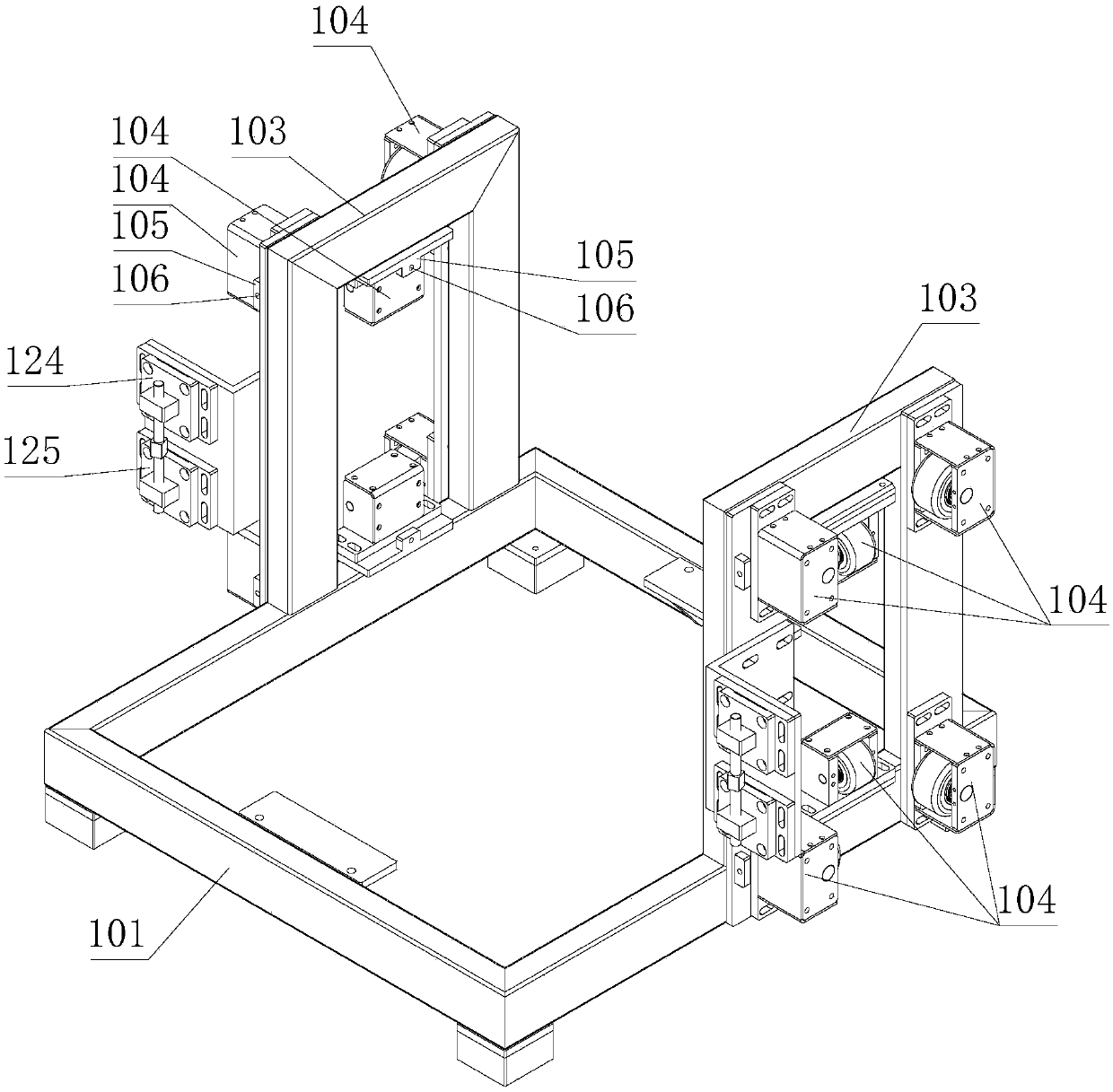

[0021] refer to figure 1 , figure 2 It is an embodiment of a stacking RGV vehicle of the present invention. A stacking RGV vehicle includes a running device and a lifting device. The running device includes a vehicle frame, two sets of wheels and a driving motor. The front end and the rear end of the car are respectively fixed with a group of wheels, and the driving motor drives one of the wheels; the lifting device includes a lifting base 101, two guide pillars 102, a lifting motor and a timing belt, and the vehicle frame at the front and rear of the lifting base 101 A guide post 102 is respectively arranged on the top, the lifting base is placed on the vehicle frame between the two guide posts, the lifting motor is fixed on the vehicle frame, and the lifting motor drives the lifting base to go up and down through the synchronous belt, and the vehicle frame is provided with a power supply for the motor. The storage battery 18.

[0022] Each group of wheels includes two roa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com