A five-sided valve structure

A valve core and valve shell technology, applied in the field of five-sided valve structure, can solve the problems of limited use site, leakage of water and electricity, and energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

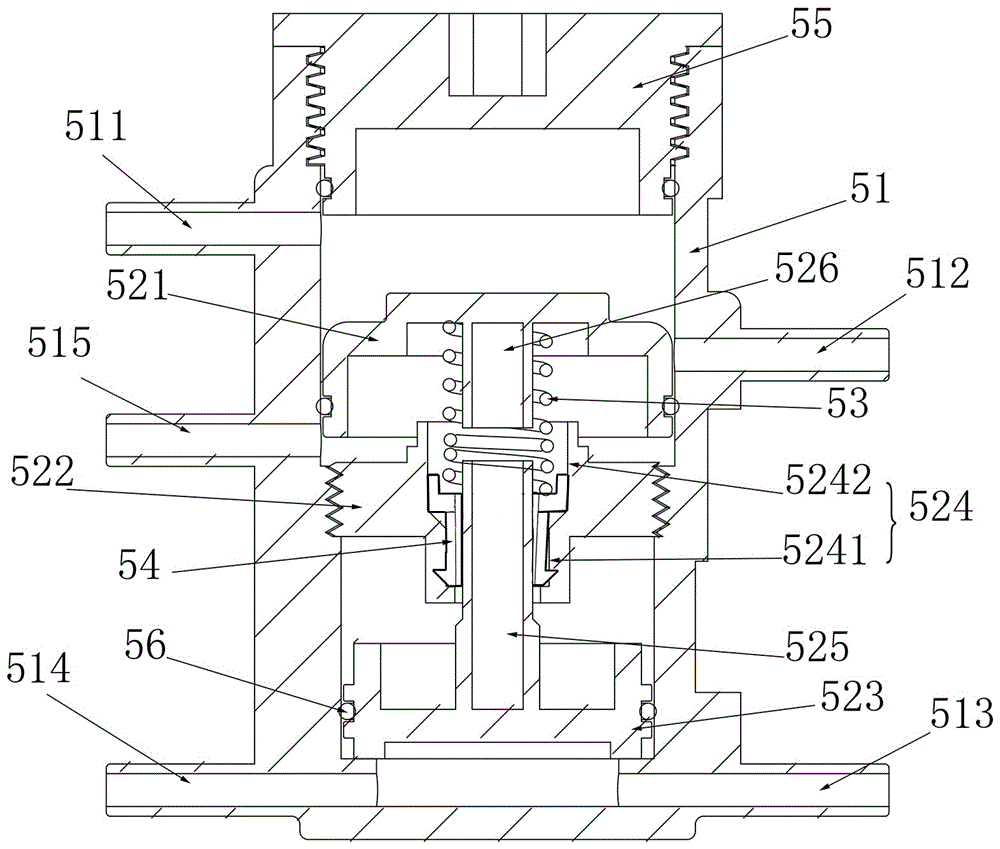

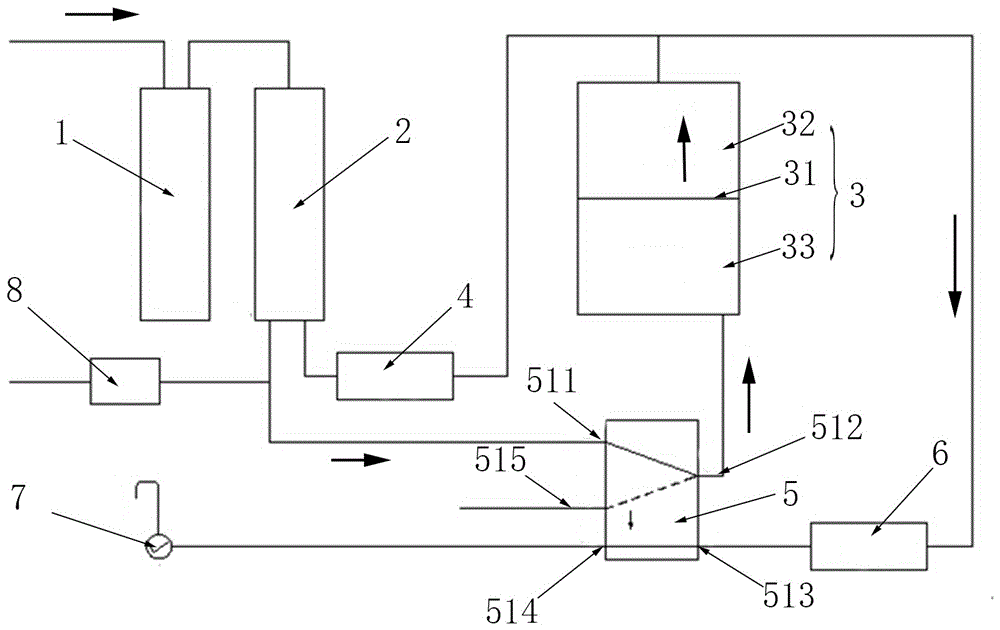

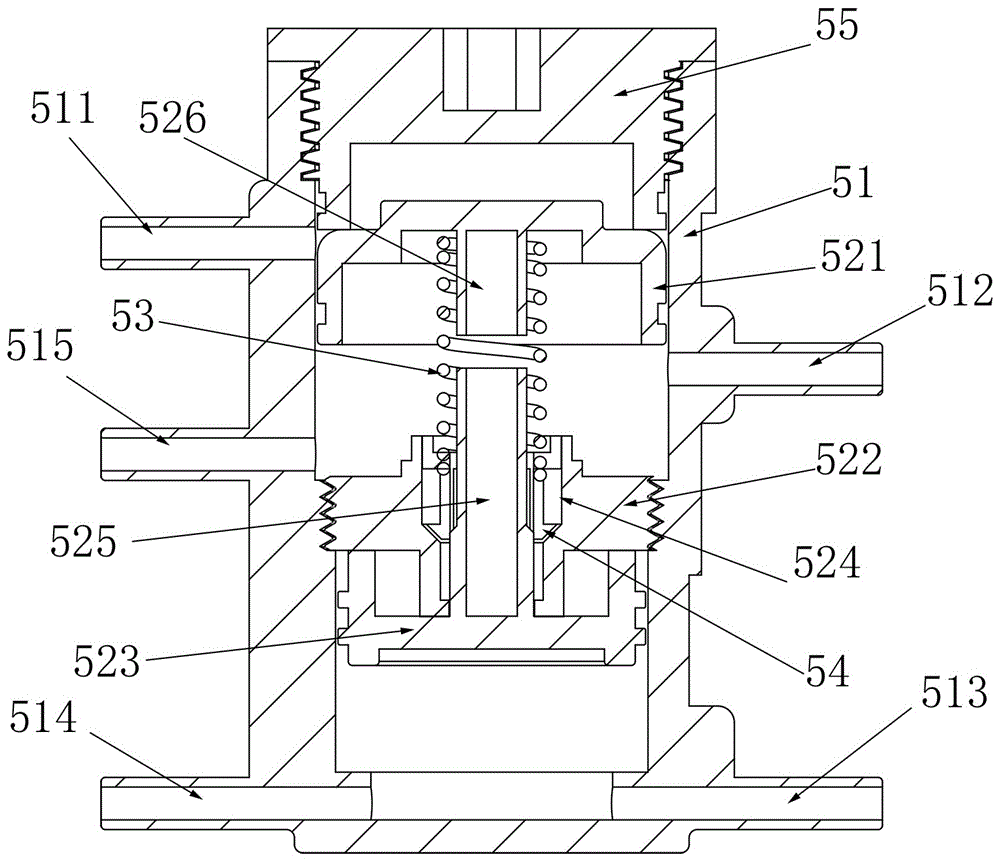

[0019] See attached picture. The five-sided valve 5 of the present embodiment includes a valve housing 51, a valve core, an upper cover 55 and a spring 53; There are five ports; the valve core is placed in the valve housing 51 and fixed by the upper cover 55; the valve core is divided into an upper valve core 521, a fixing part 522 and a lower valve core 523, and the fixing part 522 is fixed on the On the inner wall of the valve housing 51, the center of the fixing member 522 has a through hole 524, and a buckle 54 is built in the through hole; Buckle 54 ; the upper valve core 521 has a spring positioning post 526 , one end of the spring 53 is against the buckle 54 in the center of the fixing part 522 , and the other end is sleeved on the spring positioning post 526 . The outer circumference of the upper spool 521 and the lower spool 523 is provided with an annular sealing groove, and a sealing member 56 is installed in the sealing groove, and the upper spool 521 , the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com