Method for evaluating service life of accessory of aircraft engine

An aero-engine and engine technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of not fully reflecting the actual life of accessories, backwardness, and huge cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

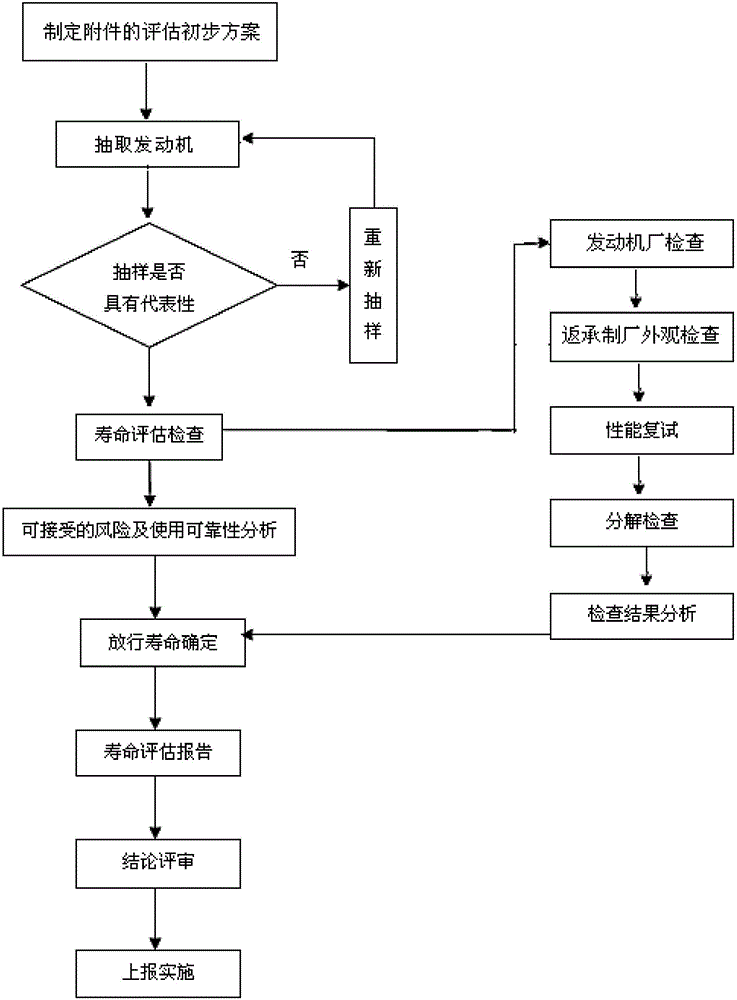

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , the evaluation method of aero-engine accessory life of the present invention, comprises the following steps:

[0021] 1) Formulate a preliminary plan for the assessment of the annex;

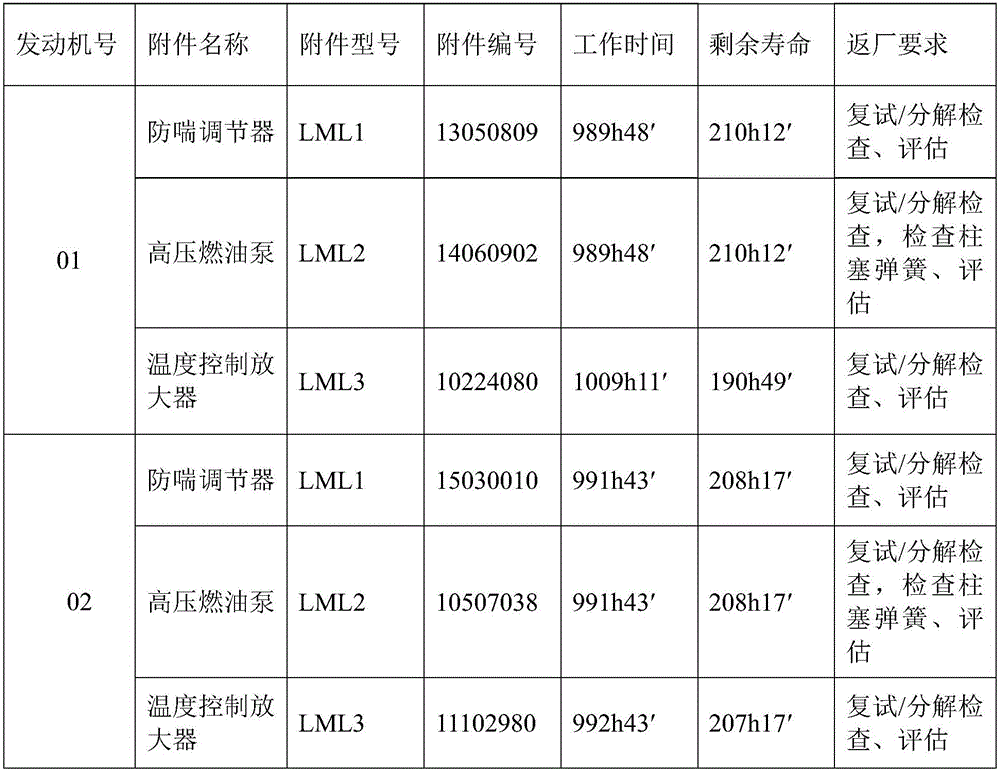

[0022] After a certain engine has been used for 1000 hours, the anti-surge regulator, high-pressure fuel pump, and temperature-controlled amplifier accessories are extracted for return to the factory for evaluation. It is planned to release the three accessories of the anti-surge regulator, high-pressure fuel pump, and temperature-controlled amplifier until 1200 hours. To this end, the "Letter on the 1000-hour life assessment of some accessories of No. 01 and No. 02 engines" was prepared.

[0023] 2) extract the engine;

[0024] According to the principle of life priority, the accessories with the first release life are selected first to return to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com