A failure assessment method for "four tubes" of boilers based on on-site state inspection parameters

A technology for testing parameters and failure assessment, which is applied in the field of power industry and can solve problems such as cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

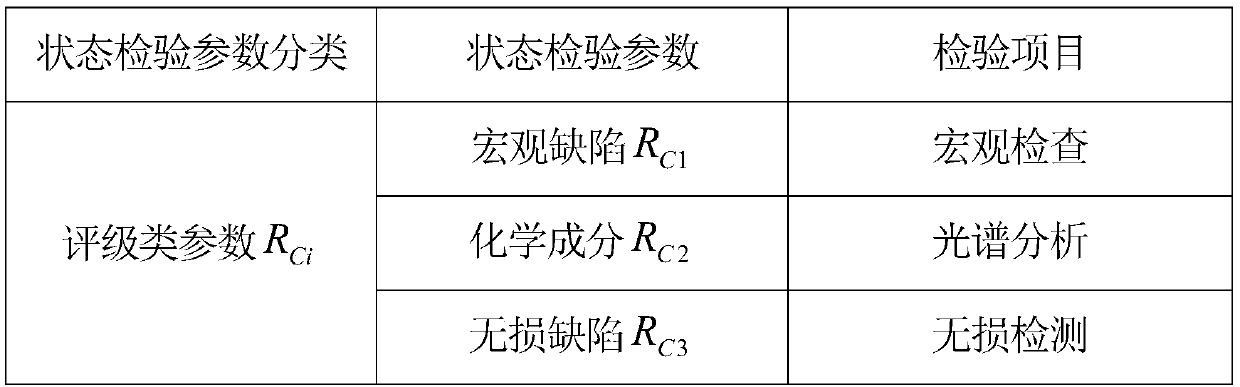

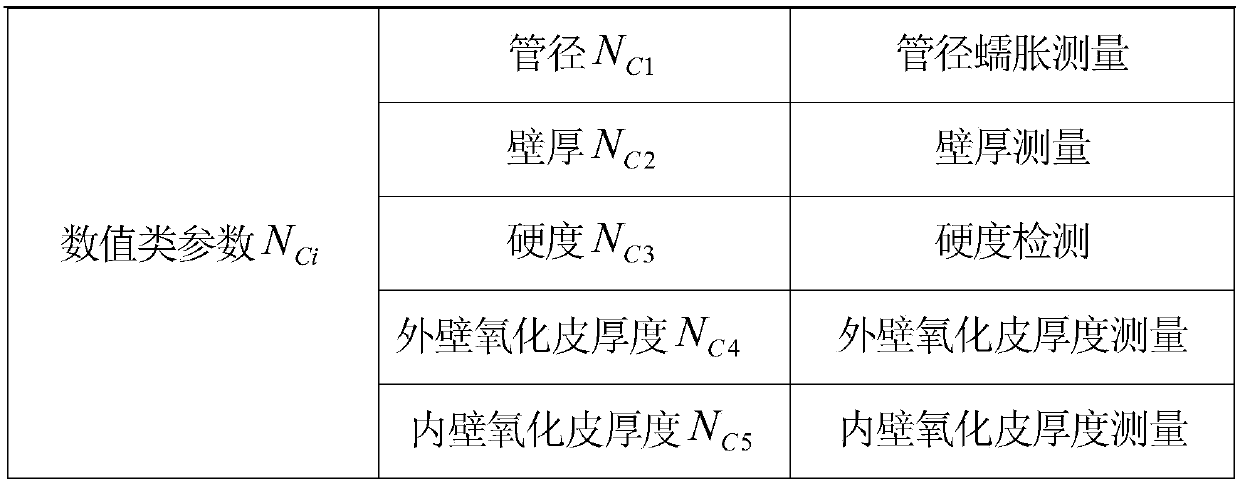

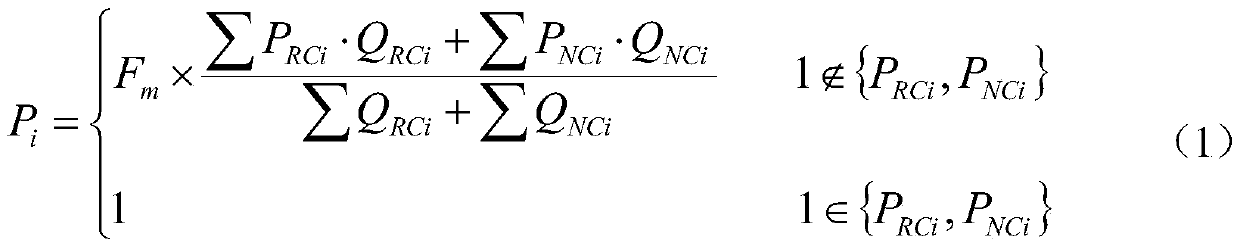

Embodiment Construction

[0057] 1) Clarify the evaluation object and basic information

[0058] First of all, it is clear which part of the boiler's "four-pipe" economizer, water wall, superheater and reheater the evaluation object is. In order to know the actual state of each furnace tube of the component in detail, it is generally recommended to select multiple locations (straight pipe, elbow or weld) on a furnace tube for inspection. Since this inspection point will eventually participate in the failure probability assessment, Therefore, it can also be called an evaluation point. In addition, it is also necessary to collect basic information on the design pipe diameter, design wall thickness, and design material of clear evaluation points.

[0059] 2) Clarify the life cycle stage of the assessment object

[0060] The failure probability of the "four tubes" of the boiler is closely related to its life cycle stage. In the early stage of the life cycle of the components, the failure probability is h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap