A 3D printing method for side elevation dyeing

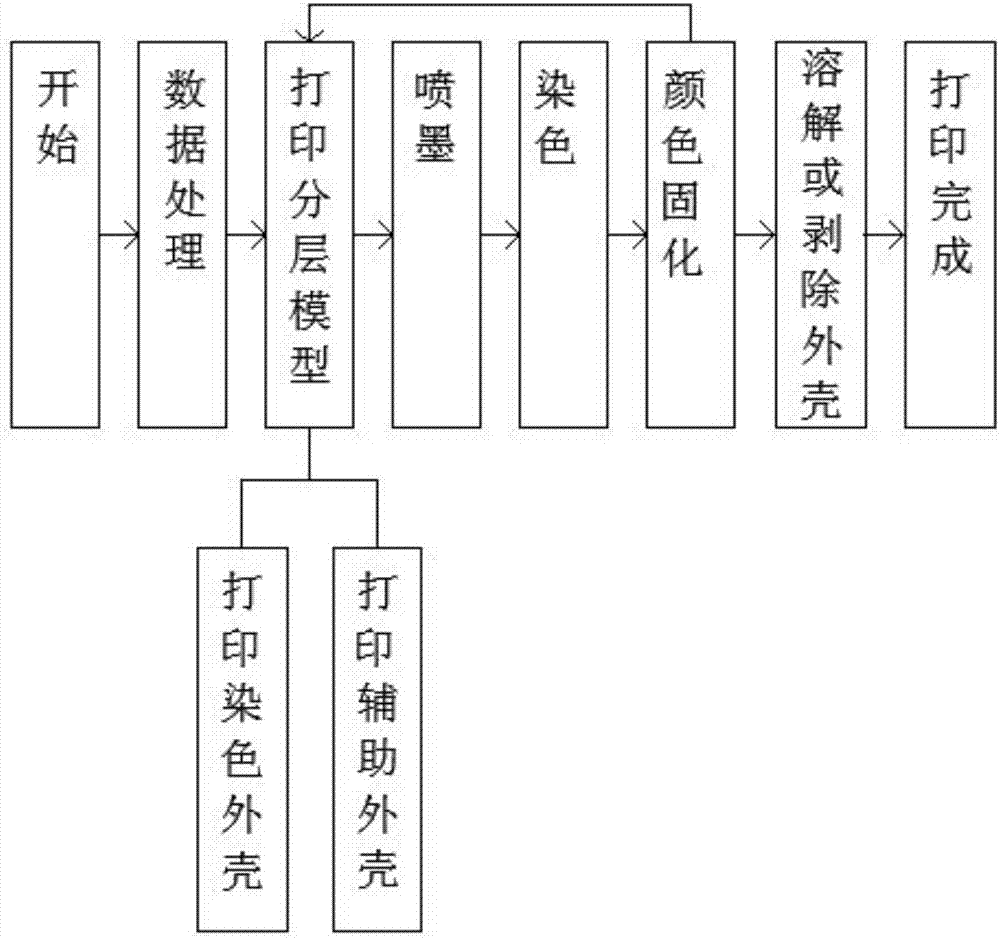

A 3D printing and side elevation technology, which is applied in the field of 3D printers and printer equipment, can solve the problems that the direction of ink drop penetration is not easy to control, cannot meet the requirements of side elevation dyeing, and the color of imaging points on the side elevation is missing, etc., to achieve printing Good dyeing effect, good application prospect, color controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The color three-dimensional printer shown in this embodiment is a triangular columnar 3D printer. For the specific structure, please refer to the appendix of the instruction manual. Figure 5 Shown:

[0068] Including color ink cartridge 4, frame 5, movable platform 6, high-permeability filament extrusion head 7, low-permeability filament extrusion head 8, color ink nozzle 9, loading platform 10, base 11, high-permeability material Silk storage box 13, low-permeability material filament storage box 15 and corresponding conduit 14, the frame of triangular columnar 3D printer is installed on the base, and a liftable loading platform 10 is installed at the lower end of the inside of the frame. A movable platform 6 is driven and installed in the frame above the platform, and the lower end of the movable platform is respectively equipped with a high-permeability filament extrusion head 7, a low-permeability filament extrusion head 8, and a color ink nozzle 9, and a high-perm...

Embodiment 2

[0076] The color three-dimensional printer shown in this embodiment is a kind of XYZ three-axis three-axis three-dimensional printer. Image 6 Shown:

[0077] It includes a movable platform 6, a high-permeability filament extrusion head 7, a low-permeability filament extrusion head 8, a color ink nozzle 9, a loading platform 10 and a base 19, and the loading platform 10 is installed in the middle of the base. The platform is used to carry 3D printed objects. Z-axis columns 18 are fixed vertically at the four corners of the base on the outer periphery of the platform, and a Y-axis slideway 17 is fixed horizontally at the upper ends of the Z-axis slides on the left and right sides. 1. An X-axis slideway 16 is installed for horizontal movement between the Y-axis slideways on the right sides, and the X-axis slideway can move along the Y-axis slideway; a movable platform 6 is installed on the X-axis slideway, which can The mobile platform can move along the X-axis guideway;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com