Composite woven and knitted bubble shirt shell fabric

A technology for composite fabrics and shirt machines, applied in the field of fabrics and textile fabrics, can solve the problems of no three-dimensional effect and achieve the effect of enhancing the three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

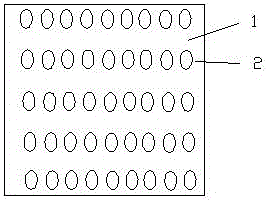

[0010] see figure 1 , The present invention relates to a woven and knitted composite fabric for a bubble shirt, comprising a shirt fabric body 1, and a plurality of rows of bubbles 2 are arranged on the outer surface of the shirt fabric body 1 . The bubbles 2 are heat-pressed to have an oval shape and protrude from the fabric body 1 .

[0011] The fabric body 1 is made of fabric, one side of the fabric is a woven fabric, and the other side is a knitted fabric. An anti-ultraviolet layer is arranged under the fabric, and the anti-ultraviolet layer is formed by interweaving warp yarns and weft yarns. The warp yarns and weft yarns are cotton yarns or polyester yarns, and the surface of the warp yarns or weft yarns is coated with an anti-ultraviolet protective layer. The fabric layer The periphery is covered with an elastic coating made of PU material. The protective layer is a titanium dioxide layer. The inner surface of the anti-ultraviolet layer is provided with a soft air-pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com