Multi-ink-box printing system with electromagnetic oscillation device

A printing system and electromagnetic oscillation technology, applied in printing and other fields, can solve problems such as adverse effects on picture quality, increased cost of ink cartridges, lack of ink cartridges, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will now be described in conjunction with the accompanying drawings.

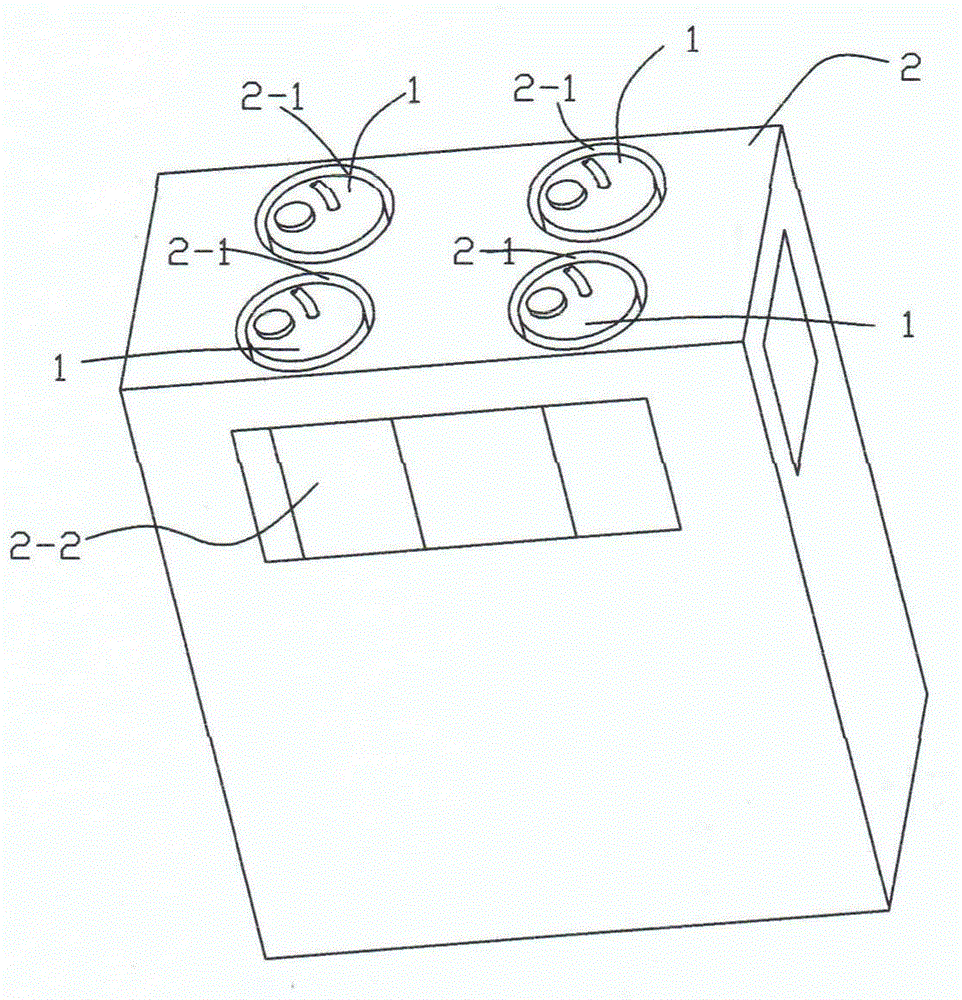

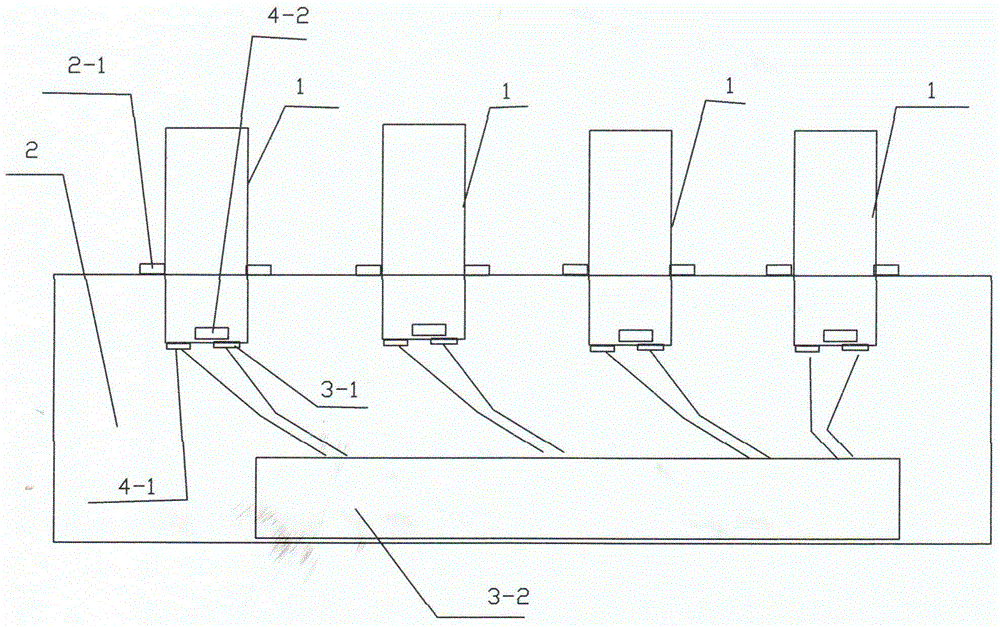

[0013] figure 1 It is a schematic diagram of the first preferred embodiment of the multi-ink cartridge printing system with electromagnetic oscillation device with oscillation and heater in the present invention. Such as figure 1 As shown, the multi-functional multi-ink cartridge ink supply box device with vibration and constant temperature functions includes a plurality of ink cartridge containers 1, a box body 2 for accommodating the ink cartridge containers, an automatic heating heater and a vibration device, the box The body is divided into upper and lower layers. The upper layer of the box body is provided with several independent spaces 2-1 for accommodating the ink cartridge container, and the lower layer is used to store the vibration equipment. The vibration equipment includes the vibration generation element 3-1 and the control circuit board. 3-2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com