Fireproof wall and gasification device and method

A gasification device and fire-resistant wall technology, applied in the field of gasification devices capable of liquid slag discharge, can solve the problems of reducing carbon-containing fuel gasification productivity and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

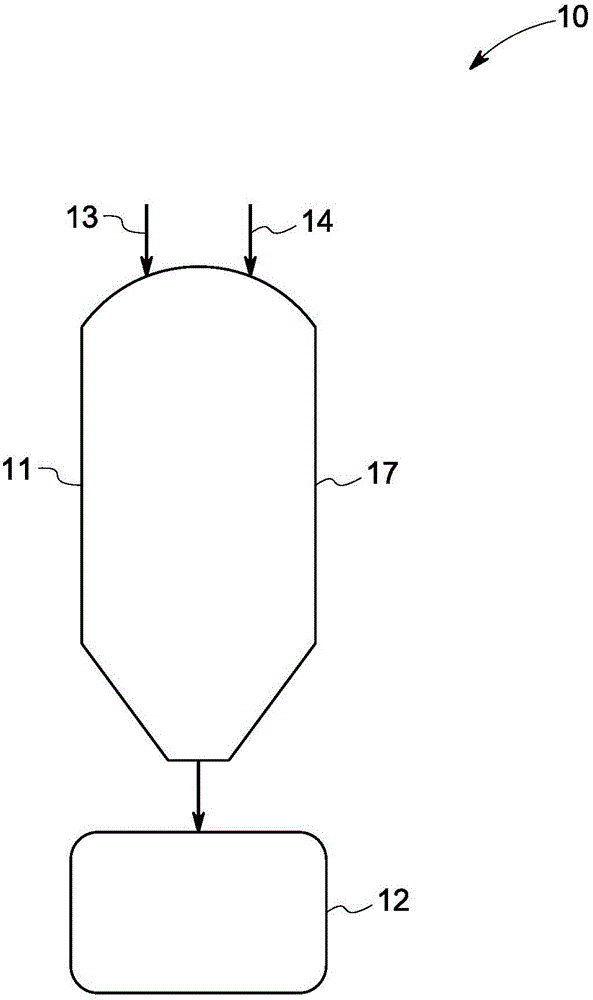

[0012] figure 1 Shown is a schematic diagram of one embodiment of a gasification apparatus 10 of the present invention for gasification of carbonaceous fuels, such as coal. In the embodiment of the present invention, the gasification device 10 is not limited to any specific gasification device. In some embodiments, the gasification device 10 may include a gasifier (SlaggingGasifier) capable of generating liquid slag during operation. In some other embodiments, the gasifier producing liquid slag may comprise an entrained bed gasifier. During operation, a portion of the ash in the entrained bed gasifier may be removed in the form of slag, for example when the entrained bed gasifier operates at a temperature higher than the temperature at which the ash is melted. In addition, a portion of coal ash is produced as a dry fine powder and / or a black fine powder slurry.

[0013] like figure 1 As shown, the gasification device 10 includes a gasification device 11 . In some embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com